Compound thickening agent and preparation method thereof

A thickening agent and matching technology, which is applied in the field of printing and dyeing auxiliaries, can solve the problems of increasing the volume of aggregates and difficulty of movement, low paste-forming rate of thickener white paste, and low efficiency of de-paste, etc. Improve thickening efficiency, improve the effect of thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

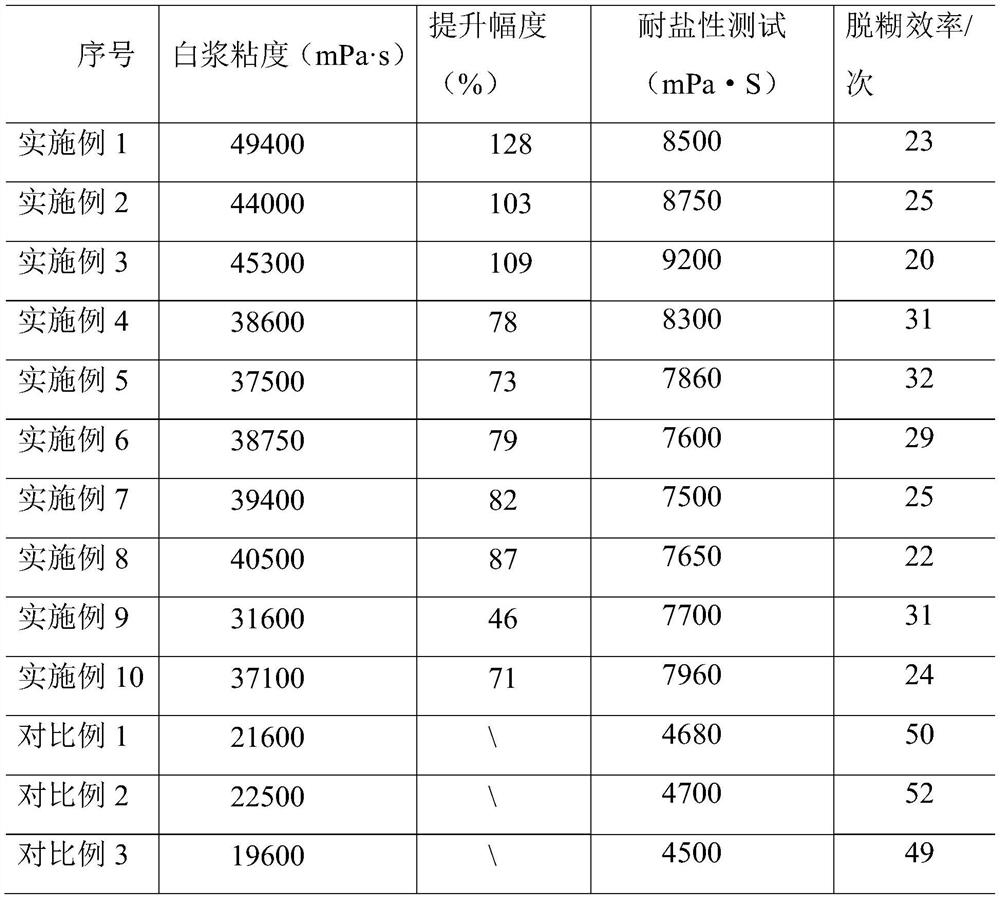

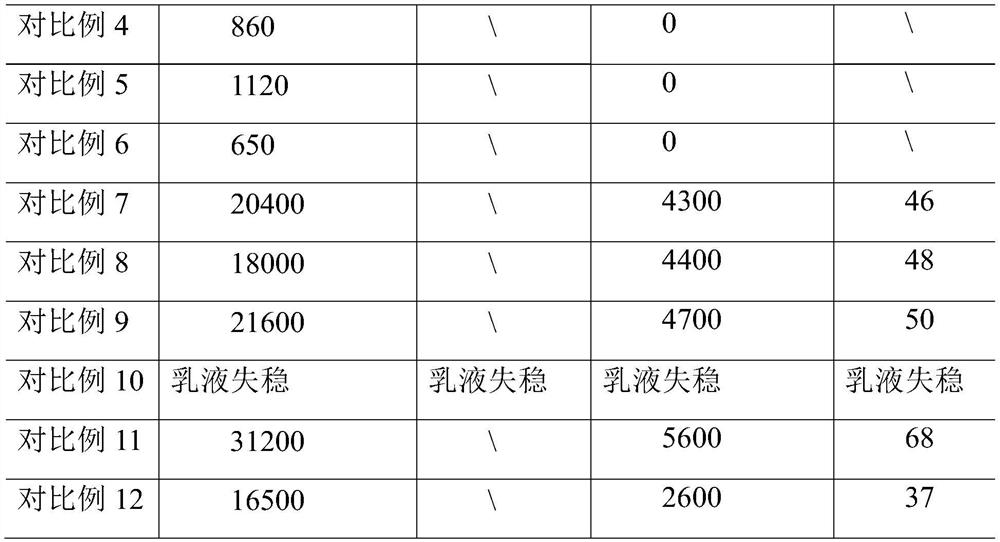

Examples

preparation example Construction

[0059] The present invention also provides a kind of preparation method of described composite thickener, comprises the steps:

[0060] (1) Carry out reverse-phase suspension polymerization of unsaturated cationic monomers, crosslinking agents and functional monomers in hydrocarbon solvents under the action of initiators and emulsifiers, and then invert phases to obtain cationic emulsions;

[0061] (2) Under the action of initiator and emulsifier, unsaturated acidic monomers, crosslinking agents and functional monomers are subjected to reverse phase suspension polymerization in hydrocarbon solvents and then phase inversion to generate acrylic anionic emulsions;

[0062] (3) Compounding the cationic emulsion described in step (1) with the acrylic anionic emulsion described in step (2) to obtain the composite thickener.

[0063] In some embodiments, step (1) includes the following sub-steps:

[0064] (1-1) Preparation of water phase: dissolve unsaturated cationic monomers and f...

Embodiment 1

[0078] Preparation of the cationic emulsion: 14 g of dimethyl diallyl ammonium chloride, 2 g of potassium persulfate, 34 g of acrylamide and 30 g of deionized water were uniformly mixed under stirring at room temperature to prepare an aqueous phase. 2g of diallyl phthalate, 5g of sorbitan monooleate, and 35g of kerosene were uniformly mixed to form an oil phase. Add the water phase to the oil phase, stir and emulsify at 700rpm for 10min to obtain a stable emulsion. Under the protection of nitrogen, raise the temperature of the emulsion in the flask to 50-60°C, the reaction will start gradually, and the temperature of the system will gradually rise. After reaching room temperature, 3 g of Pingpinga O was added and stirred for 10 min. The average particle size Z-average of the cationic emulsion was measured to be 3.5um.

[0079] Preparation of anionic emulsion: neutralize 50g of acrylic acid with 70g of liquid caustic soda under stirring at room temperature, and add 0.5g of po...

Embodiment 2

[0082] Preparation of the cationic emulsion: 10 g of methacryloyloxyethyltrimethylammonium chloride, 3 g of ammonium persulfate and 30 g of deionized water were uniformly mixed under stirring at room temperature to obtain an aqueous phase. 3g of divinylbenzene, 34g of ethyl acrylate, 5g of sorbitan monostearate, and 35g of kerosene were uniformly mixed to form an oil phase. Add the water phase to the oil phase and stir at 600rpm for 15min to obtain a stable emulsion. Under the protection of nitrogen, raise the temperature of the emulsion in the flask to 50-60°C, the reaction will start gradually, and the temperature of the system will gradually rise. To room temperature, add 3g Pingpingjia A-25, and stir for 10min. The average particle diameter Z-average=4.8um of the cationic emulsion was measured.

[0083] Preparation of anionic emulsion: 60g of methacrylic acid was neutralized with 70g of liquid caustic soda under stirring conditions at room temperature, and 0.7g of ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com