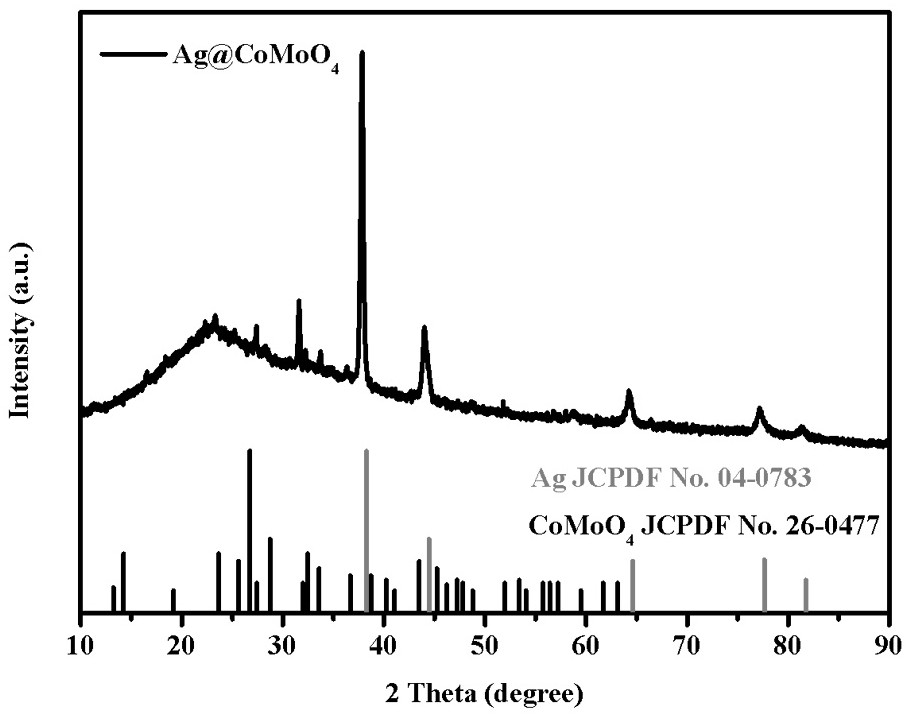

Preparation method of Ag-coated CoMoO4 oxygen evolution electrocatalyst

An electrocatalyst and catalyst technology, applied in chemical instruments and methods, electrodes, inorganic chemistry, etc., can solve problems such as poor durability, achieve good stability, good electrocatalytic performance, and increase current density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

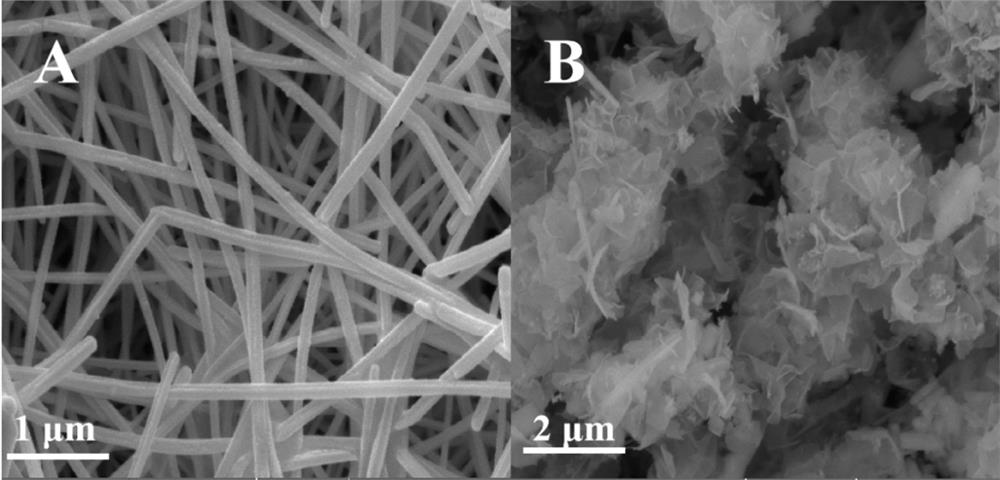

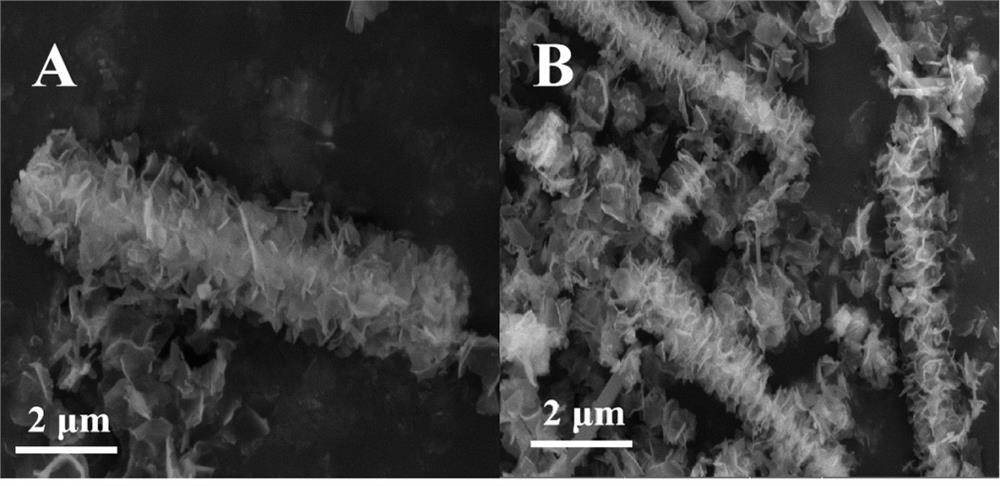

Embodiment 1

[0037]Add 375 mg of polyvinylpyrrolidone (55000) and 25 mL of 1,2-propanediol into 100 mL round bottom flasks respectively, and stir magnetically in an oil bath at 160 °C for 1 h. Add 250 μL of sodium chloride solution and 10 mL of silver nitrate solution, and continue the reaction for 40 min. After naturally cooling to room temperature, the resulting mixture was placed in a centrifuge tube, added acetone to 45 mL, and centrifuged (rotating at 8000 rpm for 5 min). Pour off the supernatant, add ethanol to 10 mL, ultrasonically disperse until uniform, add acetone to 45 mL, and centrifuge. Repeat the above operation. Disperse the product obtained above into 120 mL methanol, store it for later use, and the quantification is about 1 mg / mL.

[0038] Weigh 0.3284 g of 2-methylimidazole into a 50 mL round bottom flask, add 10 mL of methanol and 10 mL of silver nanowires, and stir magnetically. Weigh 0.291 g of cobalt nitrate hexahydrate and dissolve it in 20 mL of methanol, pour it...

Embodiment 2

[0041] Same as Example 1, except that the mixture of 10 mL of methanol and 10 mL of silver nanowires was changed to 20 mL of methanol solution, and other synthesis conditions were not changed, and CoMoO 4 catalyst.

Embodiment 3

[0043] The same as in Example 1, except that the mixture of 10 mL of methanol and 10 mL of silver nanowires was changed to a mixture of 5 mL of silver nanowires and 15 mL of methanol, and the other synthesis conditions were not changed, and Ag 5 @CoMoO 4 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com