Preparation method of photocurable hyperbranched polyurethane-epoxy acrylate

A hyperbranched polyurethane, epoxy acrylate technology, applied in polyurea/polyurethane coatings, epoxy resin coatings, coatings, etc., can solve the problems of increasing VOC emissions and production costs, reducing system viscosity, non-compliance, etc. Novel synthetic route, high hardness and flexibility, good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

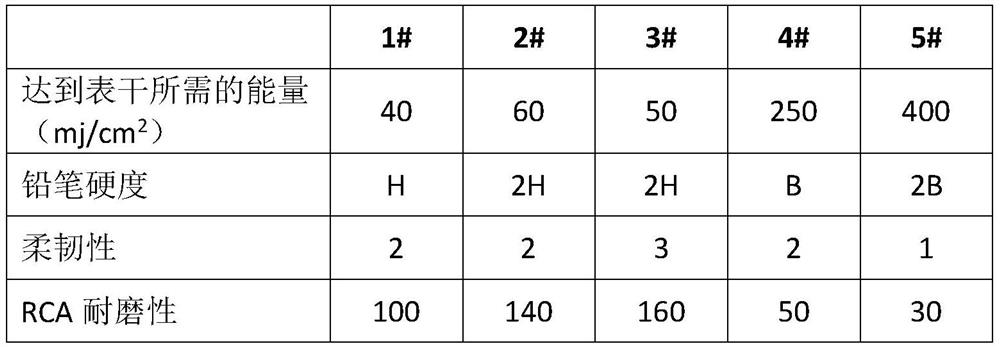

Examples

Embodiment 1

[0027] A kind of preparation method of photocurable hyperbranched polyurethane-epoxy acrylate, it comprises the following steps:

[0028] (1) After mixing 500 grams of polypropylene glycol (PPG1000) and 0.2 grams of dibutyltin dilaurate, slowly add it dropwise to 505 grams of HDI trimer (Covestro N3300), and react at 70 ° C until the NCO content reached 7.8%, the temperature of the reaction system was lowered to room temperature to obtain hyperbranched polyisocyanate.

[0029] (2) Add 149.7 grams of glycidol dropwise to the above system, add 0.05 grams of dibutyltin dilaurate, and continue to react at 80°C until the NCO content reaches below 0.2%, to obtain hyperbranched polyurethane-epoxy resin .

[0030] (3) Add a mixture of 147 grams of acrylic acid and 3.9 grams of tetrabutylammonium chloride dropwise to the above system and react at 100°C until the acid value of the system drops below 5mgKOH / g to obtain photocurable hyperbranched Polyurethane-epoxy acrylate.

Embodiment 2

[0032] A kind of preparation method of photocurable hyperbranched polyurethane-epoxy acrylate, it comprises the following steps:

[0033] (1) After mixing 176.7 grams of ethoxylated trimethylolpropane (EO9TMP) with 0.15 grams of dibutyltin dilaurate, slowly add it dropwise to 388.5 grams of isophorone diisocyanate IPDI, at 70 ° C Keeping warm until the NCO content reaches 18.6%, the temperature of the reaction system is lowered to room temperature to obtain hyperbranched polyisocyanate.

[0034] (2) Add 187.1 grams of glycidol dropwise to the above reaction system, add 0.03 grams of monobutyltin oxide, and continue to react at 80° C. until the NCO content reaches below 0.2%, to obtain hyperbranched polyurethane-epoxy resin.

[0035] (3) A mixture of 72 grams of acrylic acid, 129 grams of methacrylic acid and 3 grams of tetramethylammonium bromide was added dropwise to the above system, and reacted at 100 ° C until the acid value of the system dropped below 5 mg KOH / g, A photo...

Embodiment 3

[0037] A kind of preparation method of photocurable hyperbranched polyurethane-epoxy acrylate, it comprises the following steps:

[0038] (1) After mixing 88.7 grams of ethoxylated trimethylolpropane (EO3TMP) with 0.1 grams of dibutyltin dilaurate, slowly add dropwise to 220 grams of isophorone diisocyanate IPDI and 130.6 grams of toluene diisocyanate In the TDI mixture, keep warm at 65° C. until the NCO content reaches 23.8%, and then lower the temperature of the reaction system to room temperature to obtain hyperbranched polyisocyanate.

[0039](2) Add 185.3 grams of glycidol dropwise to the above reaction system, add 0.02 gram of stannous octoate, and continue to react at 80° C. until the NCO content reaches below 0.2%, to obtain hyperbranched polyurethane-epoxy resin.

[0040] (3) Add a mixture of 215 grams of methacrylic acid and 1 gram of tetrabutylammonium chloride dropwise to the above system, and react at 100 ° C until the acid value of the system drops below 5 mgKOH / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com