Antibacterial anti-loosening coating for titanium and titanium alloy implant materials

An implant material, titanium alloy technology, applied in the field of biomedical materials, can solve problems such as difficult to judge the antibacterial effect, cannot promote tissue and skin cell growth, and iodine coating cannot exert the strong antibacterial effect of free iodine, so as to help wounds Effects on healing, accelerated growth and wound healing, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] BPEI-NONOates preparation method among the present invention, comprises the following steps:

[0027] (1) Prepare a BPEI solution by dissolving BPEI in anhydrous methanol and tetrahydrofuran at a mass ratio of 1:4:13, and stir evenly at room temperature;

[0028] (2) Sodium methoxide (the molar ratio to BPEI is 2.5:1) was dissolved in anhydrous methanol and added to the BPEI solution, stirred evenly and placed in the internal high-pressure reactor;

[0029] (3) The high-pressure reactor was flushed twice with 140 kPa argon for 10 min each time to remove residual oxygen. Then filled with NO gas at 550 kPa, and the reaction was fully stirred at room temperature. The NO was then vented, the reactor was flushed twice with 140 kPa argon, and the product was precipitated with tetrahydrofuran / anhydrous ether. The solvent was quickly removed by filtration, and the product was washed with anhydrous diethyl ether, then dried in vacuo to give a pale yellow product. The product ...

Embodiment 1

[0031] An antibacterial and anti-loosening coating material based on titanium and titanium alloy implants and a preparation method thereof, comprising the following steps:

[0032] (1) Titanium metal samples are all round, with a diameter of 1.0 cm and a thickness of 1 mm. The titanium sheets are polished to a smooth surface with 600 mesh, 1200 mesh, 2500 mesh, and 6000 mesh sandpaper in sequence, and deionized water and The titanium sheets were ultrasonically cleaned with absolute ethanol for 15 min, and then dried in an oven at 50 °C for 12 h for later use. Prepare 30% H 2 o 2 With an acid etching solution with a volume ratio of concentrated sulfuric acid of 3:7, the cleaned and dried titanium sheet was immersed in the etching solution for 1 h, then rinsed with deionized water until neutral, and dried in an oven at 50°C for 12 h;

[0033] (2) Prepare BPEI-NONOates with BPEI with a molecular weight of 800Da and a molar ratio of primary and secondary amines of 1:1.8, and pre...

Embodiment 2

[0037] An antibacterial and anti-loosening coating material based on titanium and titanium alloy implants and its preparation method:

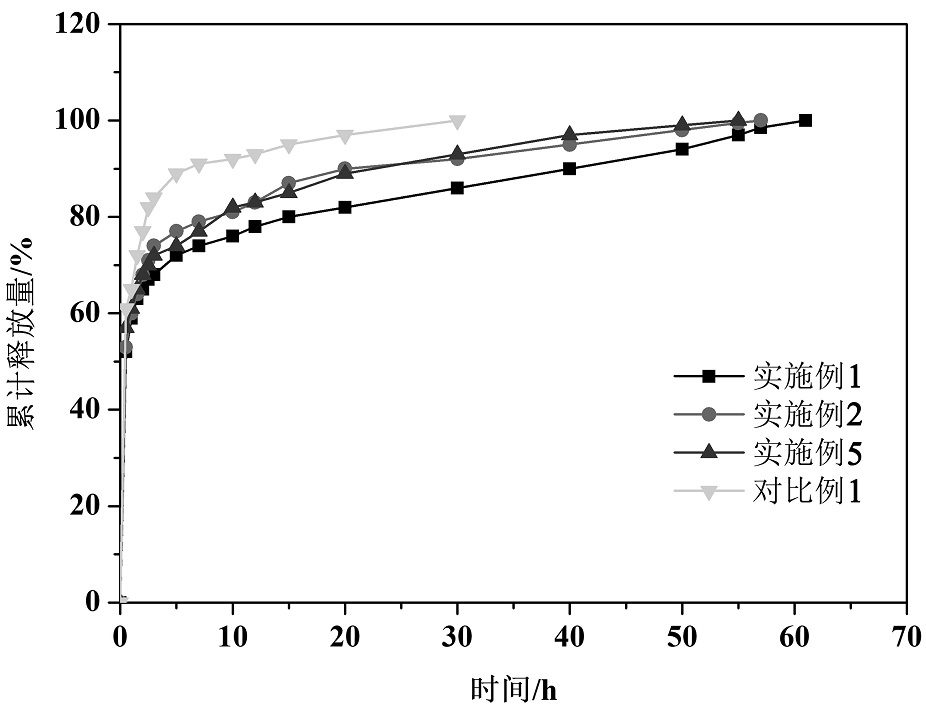

[0038] Others are the same as Example 1, the difference is that step (2) changes the molecular weight of BPEI to 500Da, the molar ratio of primary and secondary amines is 1:1.5, and then prepares BPEI-NONOates;

[0039] The NO release time of the coating prepared by this method was 55 h, and the gelatin film thickness was about 13.4 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com