Method for separating and purifying benzenediol isomer

A technology for purifying catechol and isomers, which is applied in the field of separating and purifying catechol isomers, and can solve the problem of increased investment in solvent ratio production equipment, undisclosed crystallization and purification of catechol, and different crystallization and purification methods. problems, to achieve the effect of reducing investment in production equipment, increasing dissolving capacity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

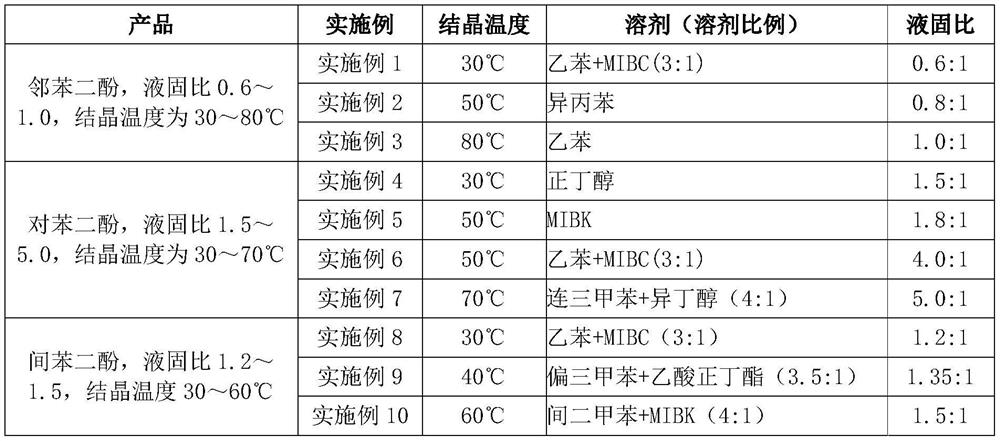

Examples

Embodiment approach

[0033](1) The aromatic hydrocarbon solvent is a benzene solvent with a boiling point of 136-176°C, for example: the aromatic hydrocarbon solvent includes but not limited to ethylbenzene, xylene isomers, trimethylbenzene isomers, , At least one of the isomers of propylbenzene and methylethylbenzene.

[0034] (2) The polar solvent uses alcohols with a boiling point of 105-176°C, ketones with a boiling point of 105-176°C or esters with a boiling point of 105-176°C; the alcohols include but are not limited to n-butyl At least one of alcohol, isobutanol, methyl isobutyl carbinol (abbreviated as MIBC), n-pentanol, isoamyl alcohol, n-hexanol, n-heptanol, 2-heptanol; the ketones include but Not limited to at least one of methyl isobutyl ketone and cyclohexanone; the esters include but not limited to at least one of n-butyl acetate, isobutyl acetate, n-pentyl acetate, and isoamyl acetate .

[0035] (3) The crude product of catechol can be the crude product of catechol with a purity o...

Embodiment 1

[0046] A method for separating and purifying hydroquinone isomers is used to separate and purify hydroquinone monomers from a certain gasified phenol slag purchased in the market. The components of the gasified phenol slag are shown in Table 1 below:

[0047] Table 1

[0048] Components of gasified phenol residue Content / wt% Catechol 31.4 Resorcinol 25.1 Quinol 16.8 4-Methylcatechol 16.2 benzoic acid 3.0 2-naphthol 1.5 2-Methylquinoline 1.3 Trimethylphenol 0.4 5-indanol 1.6 Ethyl quinone 2.7

[0049] The method for separating and purifying hydroquinone isomers may comprise the following steps:

[0050] Step A1, rectification: Take 20kg of the above gasified phenol slag and carry out vacuum rectification, the pressure at the top of the tower is 10kPa absolute pressure, the theoretical plate of the rectification tower is 30, the reflux ratio is fixed at 20, and the cooling medium at the top of the tower i...

Embodiment 2

[0053] A method for separating and purifying hydroquinone isomers, used to separate and purify hydroquinone monomers from the gasified phenol slag described in Embodiment 1 of the present invention, may include the following steps:

[0054] Step B1 is the same as Step A1 in Embodiment 1 of the present invention.

[0055] Step B2: Add 80 g of cumene solvent to 100 g of the crude catechol product, heat to dissolve the material completely, slowly cool down to 50° C. for crystallization, keep for 2 hours, separate by suction filtration to obtain 75 g of filter cake, and then filter the The cake was dried under vacuum at 100°C to obtain 64 g of pure catechol product. After testing: the catechol content of the pure catechol product is 99.9wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap