Pretreatment device and pretreatment method for high-hardness fluorine-containing wastewater

A pretreatment device, high hardness technology, applied in the field of water treatment, can solve the problems of blockage of heating pipes, frequent chemical cleaning of devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] The water quality characteristics of the wastewater treated in Example 1 are that the hardness is 300 mg / L, the pH is 7.2, the total silicon content is 87 mg / L, the fluoride ion content is 85 mg / L, the calcium ion content is 58 mg / L, and the magnesium ion content is 36 mg / L; the influent flow of wastewater is 300t / h.

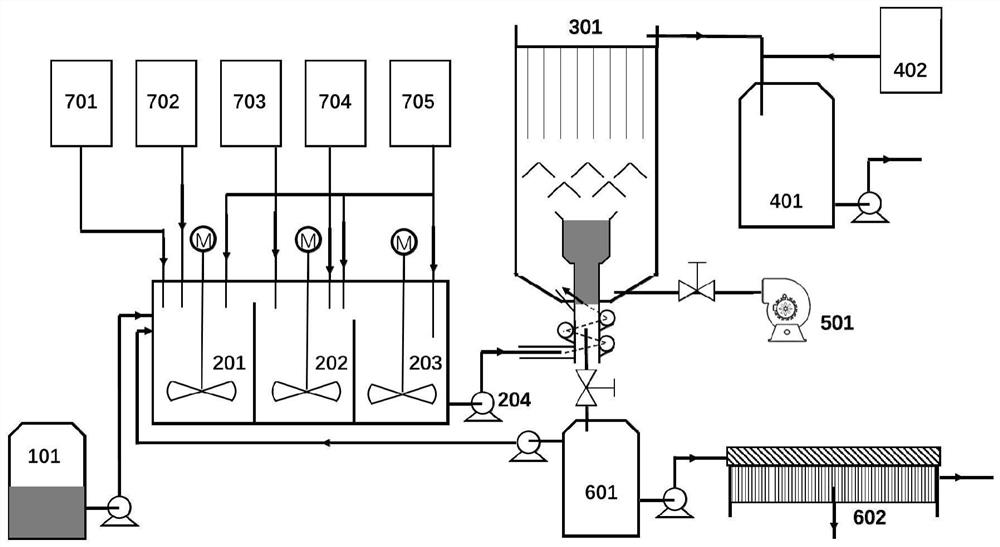

[0121] The structural representation of the pretreatment device that adopts in embodiment 1 is as figure 1 As shown, it includes a wastewater storage tank 101, a primary coagulation reaction tank 201, a secondary coagulation reaction tank 202, a tertiary coagulation reaction tank 203, a microfiltration membrane filter 301 and a water production tank 401 connected in sequence, and also includes The aeration system 501 connected to the microfiltration membrane filter 301, the mud storage tank 601 connected to the microfiltration membrane filter 301, and the plate and frame filter press 602 connected to the mud storage tank 601, wherein,

[0122] The first...

Embodiment 2

[0133] The water quality characteristics of the wastewater treated in Example 2 are that the hardness is 385 mg / L, the pH is 8.2, the total silicon content is 65 mg / L, the fluoride ion content is 96 mg / L, the calcium ion content is 75 mg / L, and the magnesium ion content is 46 mg / L; the influent flow of waste water is 200t / h.

[0134] The pretreatment device adopted in embodiment 2 is the same as embodiment 1.

[0135] The steps for preprocessing include:

[0136] (1) After the wastewater enters the primary coagulation reaction tank, add lime and polyaluminum chloride to the water body, and then add sodium hydroxide until the pH in the wastewater is 9, and the residence time of the tank body is 1.5 hours; add lime to the wastewater After the step, the mass ratio of the sum of calcium ions and magnesium ions in the waste water to the total silicon is 5:1; after the step of adding polyaluminum chloride to the waste water, the mass ratio of the aluminum ions in the waste water t...

Embodiment 3

[0143] The water quality characteristics of the wastewater treated in Example 3 are that the hardness is 486mg / L, the pH is 7.4, the total silicon content is 48mg / L, the fluoride ion content is 64mg / L, the calcium ion content is 86mg / L, and the magnesium ion content is 67mg / L; the influent flow of waste water is 350t / h.

[0144] The pretreatment device adopted in embodiment 3 is the same as embodiment 1.

[0145] The steps for preprocessing include:

[0146] (1) After the waste water enters the primary coagulation reaction tank, add lime and aluminum sulfate in the water body, then add sodium hydroxide until the pH in the waste water is 9, and the residence time of the pond body is 50min; after adding the lime step in the waste water, The mass ratio of the sum of calcium ions and magnesium ions in the waste water to the total silicon is 5:1; after the step of adding aluminum sulfate to the waste water, the mass ratio of the aluminum ions in the waste water to the fluoride io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com