Oil-stain-resistant coating for melamine tableware and preparation method of oil-stain-resistant coating

A technology for preventing oil stains and tableware, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as human health, social environmental pollution, large impact of pollution, inconvenient cleaning of tableware, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

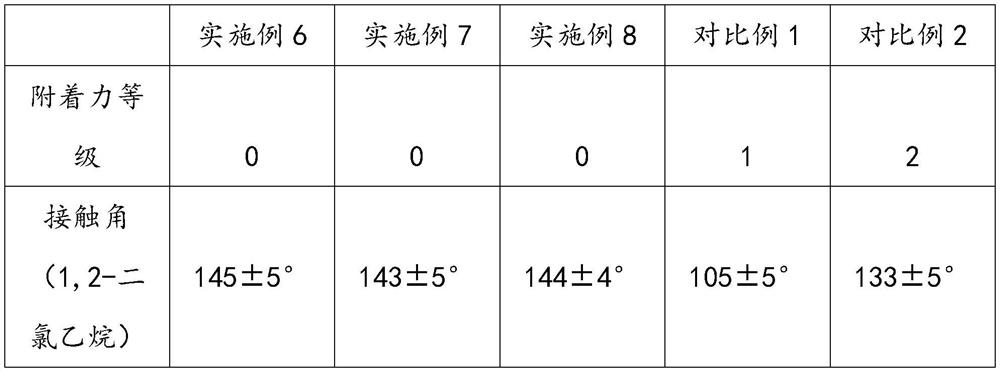

Examples

Embodiment 1

[0025] The multi-component composite powder is made by the following steps:

[0026] Step S1, adding aluminum chloride hexahydrate into 15% ethanol aqueous solution by volume fraction, stirring magnetically for 30 minutes, then adding it into a supergravity reactor, stirring at a constant speed of 2000r / min, adding an alcohol solution with a mass fraction of 10% ammonia water, and stirring at a constant speed Stir and react for 5 minutes, take it out, obtain a suspension, filter and wash with absolute ethanol three times, dry, then calcinate at 550°C for 10 hours, and then high-speed ball mill for 10 hours to obtain nanopowder, control aluminum chloride hexahydrate and ethanol The dosage ratio of the aqueous solution is 0.8mol: 1000mL, and the volume ratio of the alcohol solution of ammonia water to the aqueous ethanol solution is 0.5: 100;

[0027] Step S2: Add ethyl orthosilicate to absolute ethanol, stir at a constant speed for 15 minutes, add 10% dilute hydrochloric acid b...

Embodiment 2

[0029] The multi-component composite powder is made by the following steps:

[0030] Step S1, adding aluminum chloride hexahydrate into 15% ethanol aqueous solution by volume fraction, stirring magnetically for 30 minutes, then adding it into a supergravity reactor, stirring at a constant speed of 2000r / min, adding an alcohol solution with a mass fraction of 10% ammonia water, and stirring at a constant speed Stir and react for 5 minutes, take it out, obtain a suspension, filter and wash with absolute ethanol three times, dry, then calcinate at 550°C for 10 hours, and then high-speed ball mill for 10 hours to obtain nanopowder, control aluminum chloride hexahydrate and ethanol The dosage ratio of the aqueous solution is 0.9mol: 1000mL, and the volume ratio of the alcohol solution of ammonia water to the aqueous ethanol solution is 0.5: 100;

[0031] Step S2: Add ethyl orthosilicate to absolute ethanol, stir at a constant speed for 15 minutes, add 10% dilute hydrochloric acid b...

Embodiment 3

[0033] The multi-component composite powder is made by the following steps:

[0034] Step S1, adding aluminum chloride hexahydrate into 15% ethanol aqueous solution by volume fraction, stirring magnetically for 30 minutes, then adding it into a supergravity reactor, stirring at a constant speed of 2000r / min, adding an alcohol solution with a mass fraction of 10% ammonia water, and stirring at a constant speed Stir and react for 5 minutes, take it out, obtain a suspension, filter and wash with absolute ethanol three times, dry, then calcinate at 550°C for 10 hours, and then high-speed ball mill for 10 hours to obtain nanopowder, control aluminum chloride hexahydrate and ethanol The dosage ratio of the aqueous solution is 1mol: 1000mL, and the volume ratio of the alcohol solution of ammonia water to the aqueous ethanol solution is 0.6: 100;

[0035] Step S2: Add ethyl orthosilicate to absolute ethanol, stir at a constant speed for 15 minutes, add 10% dilute hydrochloric acid by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com