Graphene negative electrode material and preparation method and application thereof

A graphene negative electrode and graphene technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low theoretical capacity and limited electrochemical performance of lithium-ion batteries, and achieve simple preparation process and good storage capacity , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

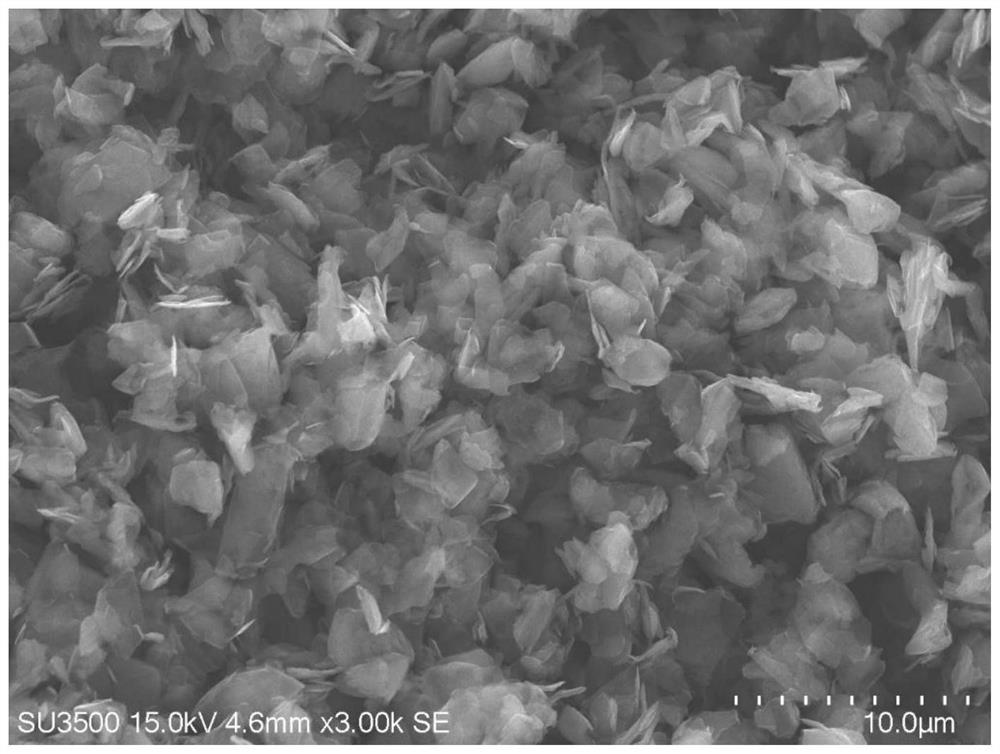

[0037] The preparation method of the graphene negative electrode material of the present invention comprises: using a jet mill to pulverize the graphene raw material to obtain the graphene negative electrode material. According to research of the present invention, by this preparation method, graphene raw material can be pulverized, obtains the graphene of smaller particle size (being graphene negative electrode material), also can have certain exfoliation simultaneously, reduces the obtained small particle size graphite The layer number and thickness of graphene, more importantly, can ensure the surface flatness of the obtained graphene, so that it has a suitable defect density, and at the same time ensure the integrity of the sheet structure of the graphene negative electrode material. Research shows that the obtained The surface of the prepared graphene negative electrode material is smooth, and there are basically no interlayer fractures, wrinkles and the like. In addition...

Embodiment 1

[0055] 1. Preparation of graphene raw material with supercritical fluid: Add natural graphite into the reaction kettle, pass carbon dioxide into it, and raise the temperature to about 50°C, control the pressure so that the carbon dioxide passed into the reaction kettle is in a supercritical state, so that the graphite raw material is in a supercritical state. The intercalation reaction is carried out in a supercritical state. After about 120 minutes of reaction, the reaction ends, and the reactor is depressurized to peel off the reacted graphite raw material to obtain the graphene raw material.

[0056] 2. Preparation of graphene negative electrode material

[0057] (1) 30g graphene raw material is divided into 5-6 times and added in jet pulverizer, to carry out stirring pulverization process under 500-3000r / min rotating speed, processing time is 24-30h, obtain pulverization product;

[0058] (2) Sieve the pulverized product, the mesh number of the sieve used is 2000-6000 mesh...

Embodiment 2

[0071] The difference between embodiment 2 and embodiment 1 is that in the step (3) of preparing graphene negative electrode material, repeat step (1) and step (2) altogether 12 times (that is, pulverize altogether 13 times), all the other conditions are the same as in embodiment 1 same.

[0072] After testing, the Raman spectrum I of this graphene negative electrode material D / I G = 0.6, the average particle size is about 800nm; XRD analysis results show: have the diffraction angle of ultrafine graphene, that is, the diffraction angle 2θ=25.4 ° of (002) interlayer spacing (its XRD pattern is shown in Figure 11 shown); the specific surface area is 2.7m 2 / g, the number of layers is 3 layers, and the carbon content is greater than 99.99%.

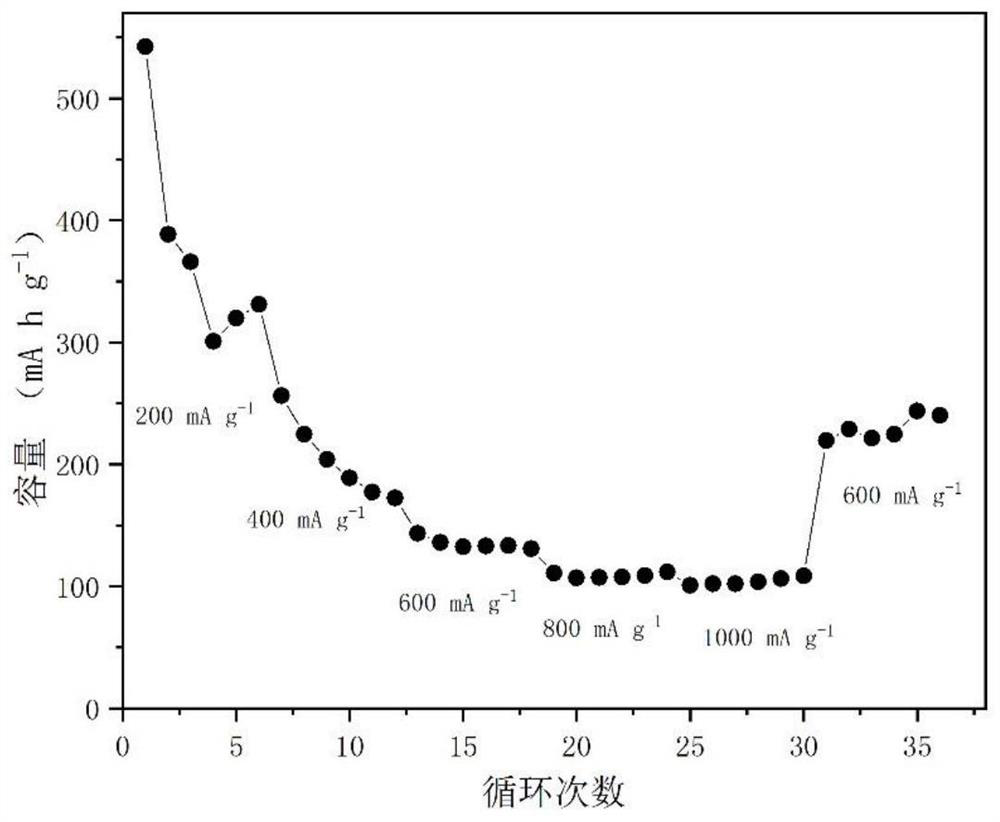

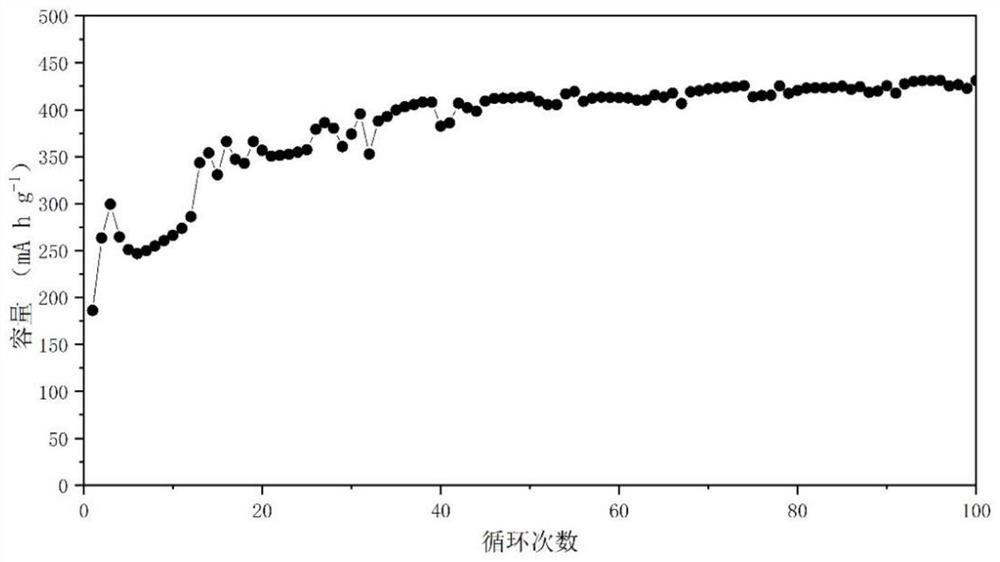

[0073] The rate performance curve of the lithium-ion battery measured in embodiment 2 is shown in Figure 4 (See Figure 4 The curve corresponding to the graphene negative electrode material in the middle), which is at 200mA g -1 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com