PDMS (polydimethylsiloxane) material containing benzimidazolyl dynamic covalent bonds as well as preparation method and application of PDMS material

A dynamic covalent bond and benzimidazole-based technology, which is applied in additive processing, prosthesis, medical science, etc., achieves the effects of lower processing temperature, wide application range, and improved dynamic adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

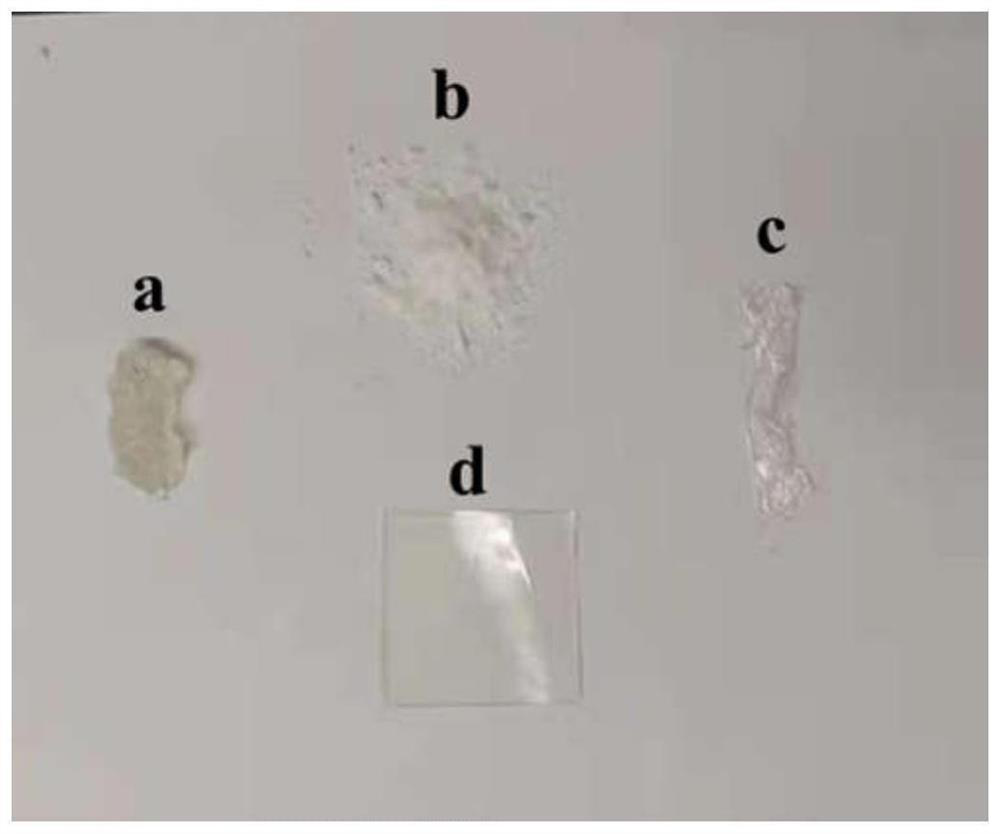

[0030] Dissolve 7.50g of modified amodimethicone DMS-A211, 0.99g of hexamethylene diisocyanate, 0.40g of 2-hydroxybenzimidazole and 2.03g of hexamethylene diisocyanate trimer in 40ml In tetrahydrofuran, stir and react at room temperature for 12 hours. After the reaction, pour the prepolymer into a polytetrafluoroethylene mold, remove the solvent at room temperature for 24 hours, remove the solvent at 50°C for 12 hours, and remove the solvent at 80°C for 12 hours. Take out and obtain the silicone rubber solid containing benzimidazolium urea bond, such as figure 1 Shown in a.

Embodiment 2

[0032] Reprocessing performance of PDMS elastomers containing benzimidazole-based dynamic covalent bonds is demonstrated.

[0033] The bulk polymer prepared in Example 1 is frozen and pulverized under liquid nitrogen conditions to obtain a polymer powder that can be used for laser sintering 3D printing (SLS), such as figure 1 Shown in b.

[0034] The bulk polymer prepared in Example 1 was melt-extruded by an extruder at 120° C. to obtain polymer strands, such as figure 1 As shown in c.

[0035] The bulk polymer prepared in Example 1 was hot-pressed at 120° C. and 10 MPa pressure for 30 minutes using a hot press to obtain a polymer sheet, such as figure 1 Shown in d.

Embodiment 3

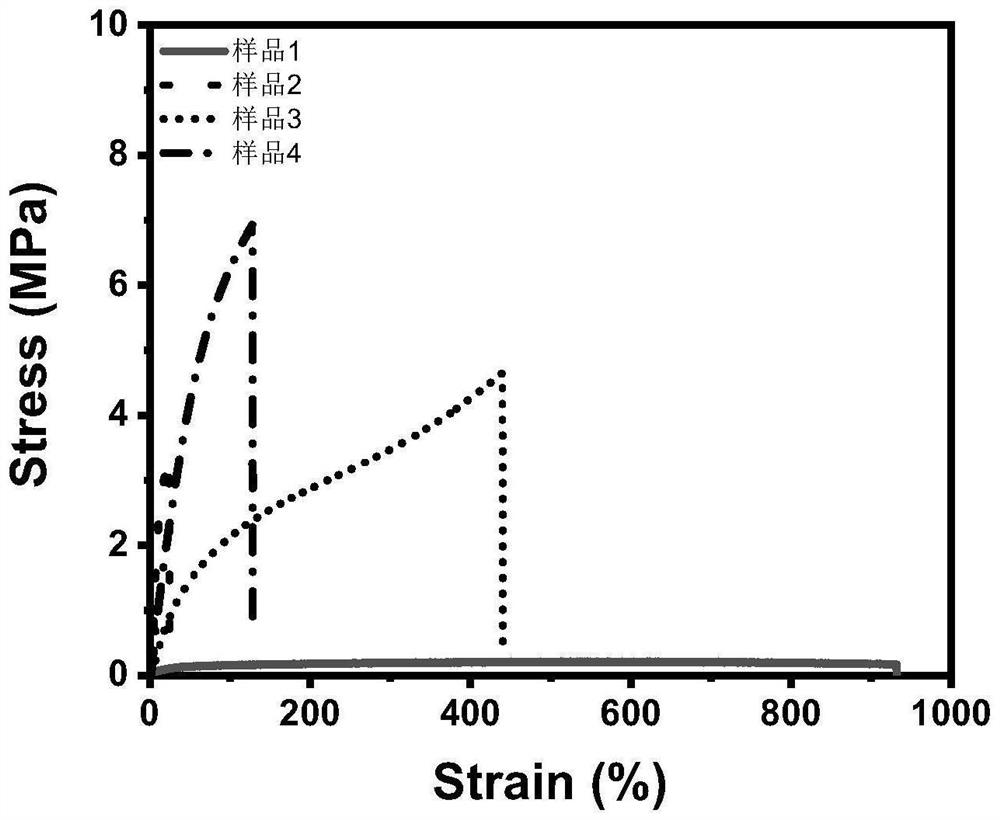

[0037] Tensile properties of PDMS elastomers containing benzimidazole-based dynamic covalent bonds. Several polymer materials with different proportions were prepared according to the method described in Example 1 and processed into polymer sheets according to the method described in Example 2. In the test, the obtained polymer sheet was cut into a dumbbell-shaped sample for testing, with a size of about 15 mm in length, 2 mm in width, and 0.8-1.5 mm in thickness. The testing machine uses a 1kN sensor at 50mm min -1 The tensile rate was uniaxially stretching the sample at 20°C, and the stress-strain curve was recorded, and 5 samples were tested in parallel for each group.

[0038] Such as figure 2 As shown, this type of material has good mechanical property adjustability (the adjustable range of elongation at break is 20%-1000%, and the adjustable range of strength is 0.01MPa-8.00MPa). Such materials can meet the mechanical performance requirements of practical application...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com