Hydrolysis-regulated slow-release mud-resistant polycarboxylate superplasticizer and preparation method thereof

A technology of anti-mud type and polycarboxylate, which is applied in the field of polycarboxylate superplasticizers, can solve the problems of high soil sensitivity and poor slump performance, so as to improve soil tolerance, slump performance, and anti-slump performance. The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

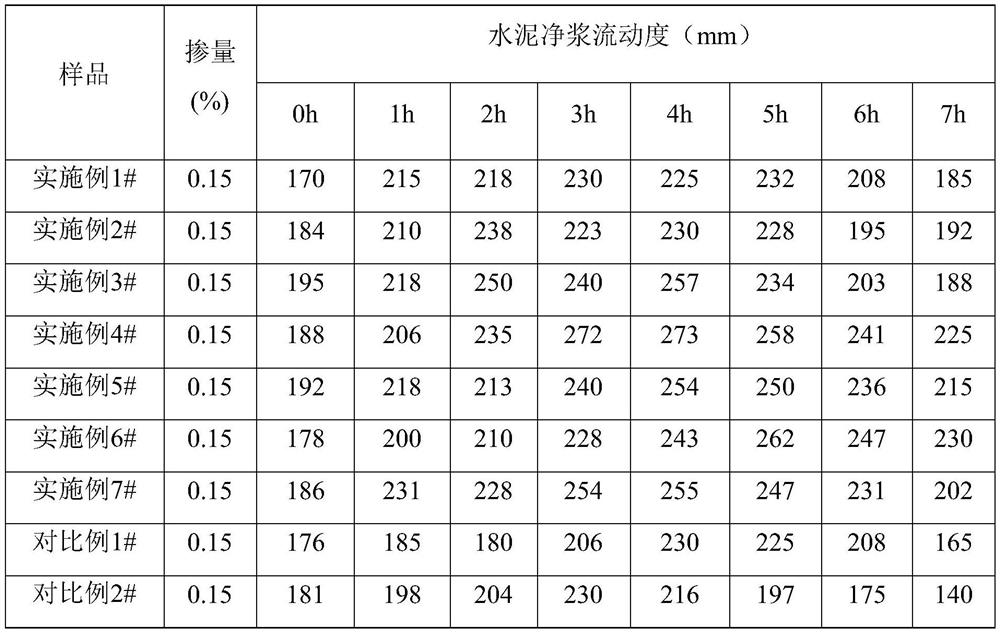

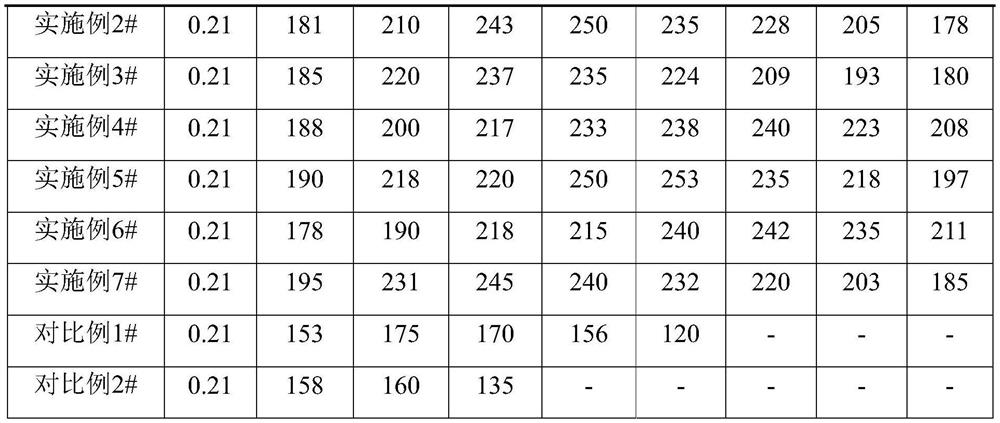

Examples

Embodiment 1

[0025] A hydrolysis-controlled slow-release mud-resistant polycarboxylate superplasticizer, the preparation method of which is as follows:

[0026] (1) In a glass reactor equipped with a thermometer and a stirrer, add 300 parts of prenol polyoxyethylene ether and 400 parts of deionized water in sequence, stir until the prenol polyoxyethylene ether is fully dissolved, then add 5 part of ammonium persulfate to obtain the reactant bottom solution;

[0027] (2) Mix 0.45 parts of sodium methylthiosulfate with 1.4 parts of thioglycolic acid and 60 parts of deionized water to make mixed solution 1; mix 10 parts of acrylic acid, 20 parts of hydroxyethyl acrylate, 10 parts of 2-hydroxyethyl Add 30 parts of deionized water after mixing methacrylate phosphate and 15 parts of methacryloyloxyethyl-ethyl-dimethylammonium bromide to make mixed solution 2;

[0028] (3) In the state of stirring, heat the bottom solution of the reactant in a water bath to raise the temperature to 20°C, first a...

Embodiment 2

[0030] A hydrolysis-controlled slow-release mud-resistant polycarboxylate superplasticizer, the preparation method of which is as follows:

[0031] (1) In a glass reactor equipped with a thermometer and a stirrer, add 300 parts of methallyl alcohol polyoxyethylene ether and 400 parts of deionized water in sequence, and stir until the methallyl alcohol polyoxyethylene ether is fully dissolved Add 2 parts of hydrogen peroxide to obtain the reactant bottom solution;

[0032] (2) Mix 1.8 parts of L-ascorbic acid with 2 parts of mercaptoethanol and 60 parts of deionized water to make mixed solution 1; mix 6 parts of acrylic acid, 8 parts of methacrylic acid, 15 parts of 2-hydroxyethyl methacrylate, Mix 10 parts of dimethylaminoethyl methacrylate and 12 parts of acryloyloxyethyltrimethylammonium chloride and add 30 parts of deionized water to make mixed solution 2;

[0033] (3) In the state of stirring, heat the reactant base solution in a water bath to raise the temperature to 50°...

Embodiment 3

[0035] A hydrolysis-controlled slow-release mud-resistant polycarboxylate superplasticizer, the preparation method of which is as follows:

[0036] (1) In a glass reactor equipped with a thermometer and a stirrer, add 300 parts of 4-hydroxybutyl vinyl polyoxyethylene ether and 400 parts of deionized water in sequence, and stir until 4-hydroxybutyl vinyl polyoxyethylene After the ether is fully dissolved, add 1 part of potassium persulfate to obtain the bottom solution of the reactant;

[0037](2) Mix 0.8 parts of L-ascorbic acid, 0.5 parts of erythorbic acid, 1.5 parts of mercaptopropionic acid, 1.8 parts of thioglycolic acid and 60 parts of deionized water to make mixed solution 1; mix 10 parts of methacrylic acid, 10 parts of Acid anhydride, 10 parts of 2-acrylamide-2-methylpropanesulfonic acid, 5 parts of hydroxypropyl acrylate, 17 parts of methacryloyloxyethyl-butyl-dimethylammonium bromide are mixed and then added to 30 parts of deionized Water, made mixed solution two; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com