Copper alloy surface polishing solution and preparation method thereof

A technology of surface polishing and copper alloy, applied in the field of metal polishing liquid, can solve the problems that the surface gloss needs to be improved, and can not have both pickling, polishing, sealing, copper alloy surface over-etching, etc., so as to improve the surface scratch repair performance , The effect of stable foaming and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

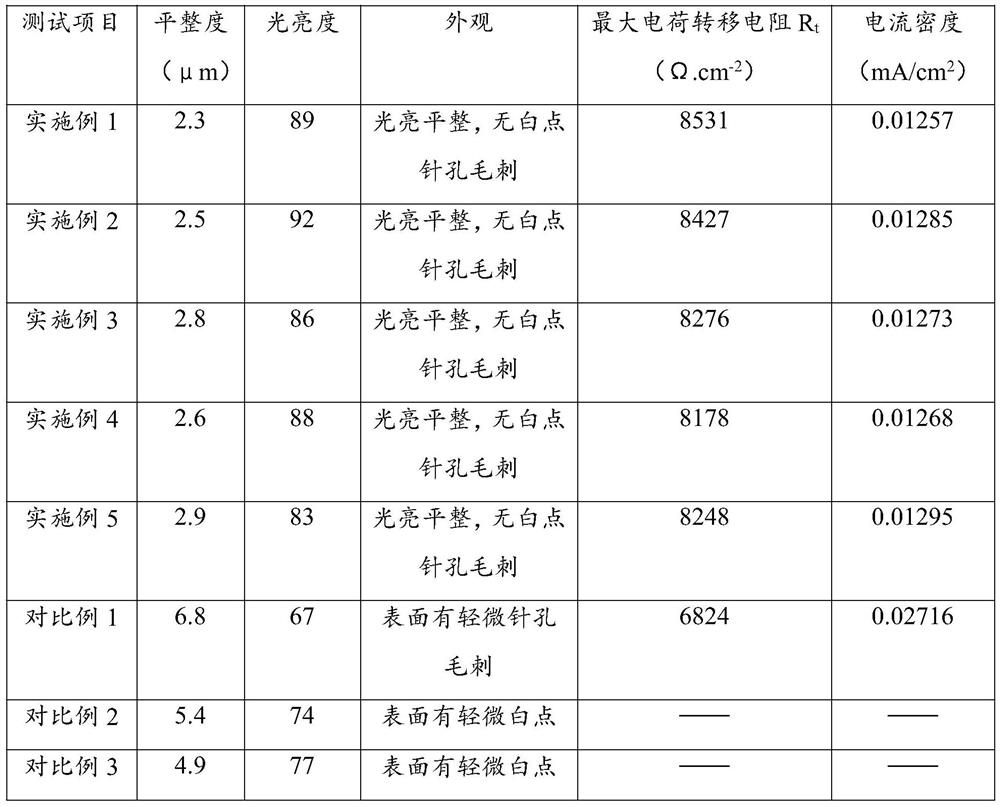

Embodiment 1

[0030] The present embodiment provides a copper alloy surface polishing solution, which includes 12vt% phosphoric acid, 8vt% sulfuric acid, 40g / L sodium chloride, 0.45g / L compound corrosion inhibitor, 0.23g / L surfactant, 8vt% methanol, 2.8g / L dodecylphenol ethoxylate, 28vt% hydrogen peroxide, 5g / L ethanol, and the rest is deionized water.

[0031] The preparation method of the copper alloy surface polishing liquid of the present embodiment comprises the following steps:

[0032] Add 5kg diethanolamine, 0.9kg quinoline, 21kg deionized water into the reaction kettle, then add 2.8kg thiourea, heat up to 92°C, keep warm and stir evenly, add 0.6kg benzotriazole, cocamide propyl hydroxyl For sulfobetaine, after cooling to room temperature, add 0.46kg sodium molybdate, keep stirring at 46°C for 25min to obtain a compound corrosion inhibitor.

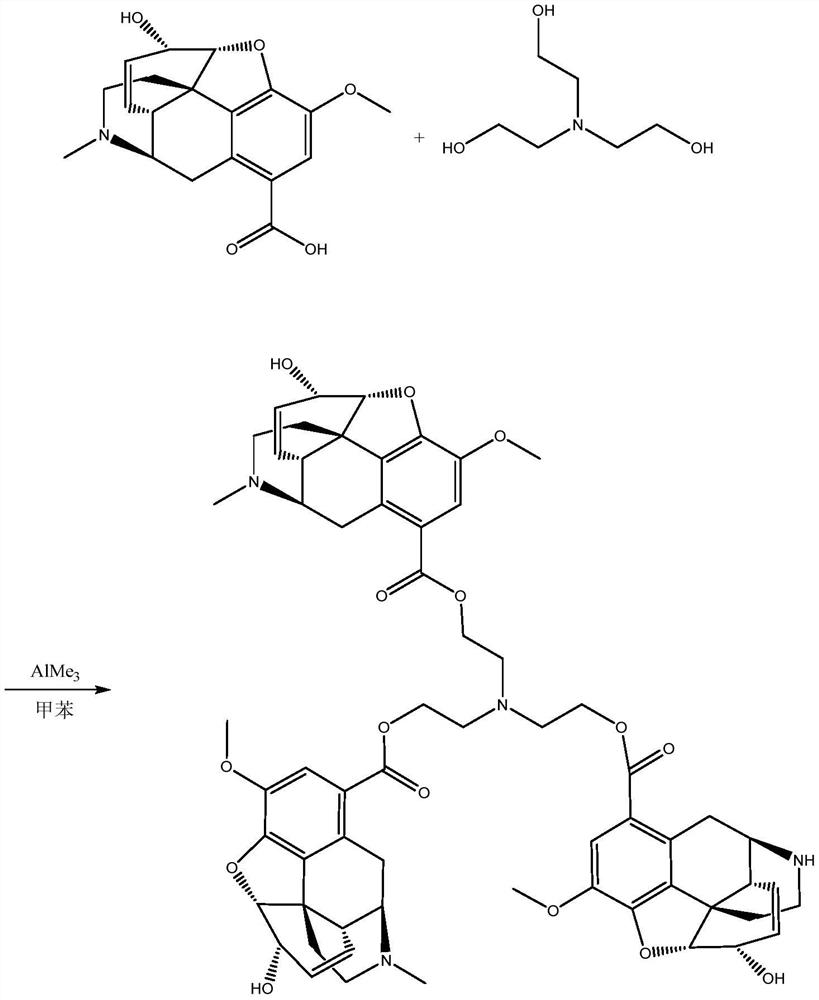

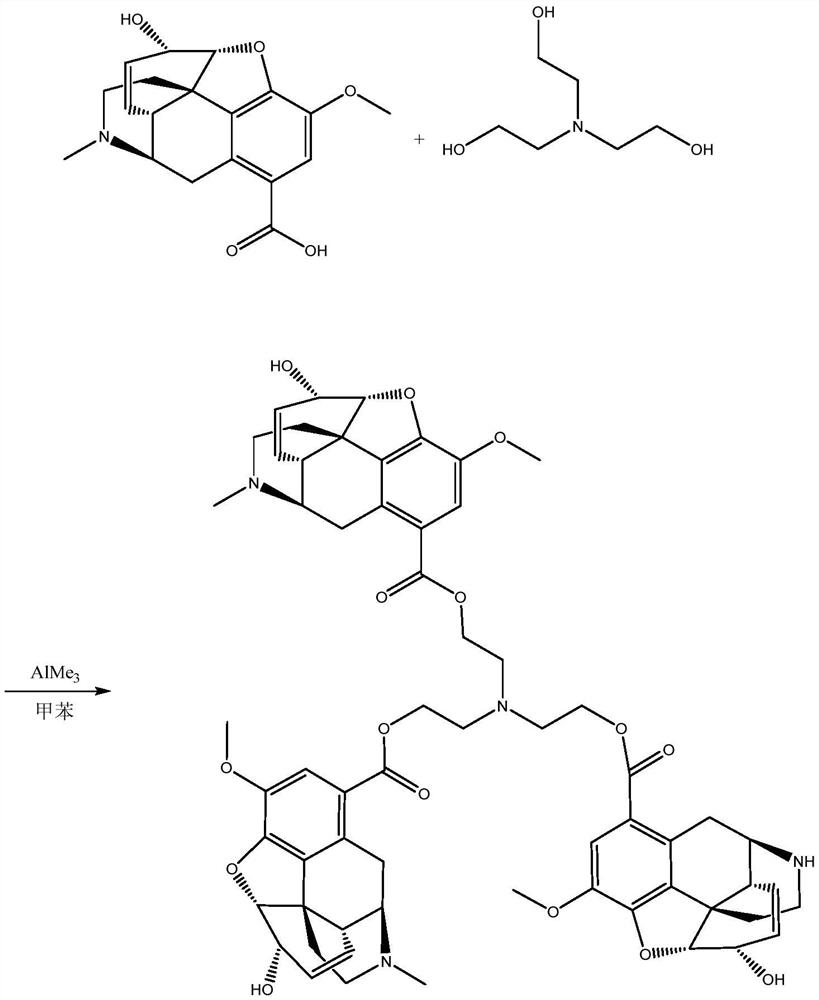

[0033] Add 12kg of cocoic acid, 75kg of toluene, and 0.25kg of catalyst trimethylaluminum successively in the reactor, raise the temperature...

Embodiment 2

[0041] The present embodiment provides a copper alloy surface polishing solution, which includes 9vt% phosphoric acid, 8vt% sulfuric acid, 39g / L sodium chloride, 0.45g / L compound corrosion inhibitor, 0.22g / L surfactant, 7vt% methanol, 2.8g / L dodecylphenol ethoxylate, 30vt% hydrogen peroxide, 7g / L ethanol, and the rest is deionized water.

[0042] The preparation method of the copper alloy surface polishing liquid of the present embodiment comprises the following steps:

[0043] Add 5kg diethanolamine, 1.3kg quinoline, 20kg deionized water into the reaction kettle, then add 2.5kg thiourea, heat up to 92°C, heat and stir evenly, then add 0.7kg benzotriazole, 0.09kg cocoamidopropyl Hydroxysultaine, cooled to room temperature, added 0.09kg sodium molybdate, and stirred at 47°C for 27 minutes to obtain a compound corrosion inhibitor.

[0044] Add 12.35kg of coconut oil, 100kg of toluene, and 0.36kg of catalyst trimethylaluminum to the reactor in turn, raise the temperature to 72°...

Embodiment 3

[0048] The present embodiment provides a copper alloy surface polishing solution, which includes 14vt% phosphoric acid, 8vt% sulfuric acid, 42g / L sodium chloride, 0.45g / L compound corrosion inhibitor, 0.19g / L surfactant, 8vt% methanol, 3.2g / L dodecylphenol ethoxylate, 28vt% hydrogen peroxide, 6g / L ethanol, and the rest is deionized water.

[0049] The preparation method of the copper alloy surface polishing liquid of the present embodiment comprises the following steps:

[0050] Add 5kg diethanolamine, 1.2kg quinoline, 20kg deionized water into the reaction kettle, then add 3.5kg thiourea, heat up to 92°C, heat and stir evenly, then add 0.8kg benzotriazole, 0.12kg cocoamidopropyl Hydroxysultaine, after cooling to room temperature, add 0.56kg sodium molybdate, keep stirring at 48°C for 25min to obtain compound corrosion inhibitor.

[0051] Add 12.70kg of cocoic acid, 110kg of toluene, and 0.21kg of catalyst trimethylaluminum to the reaction kettle in sequence, raise the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com