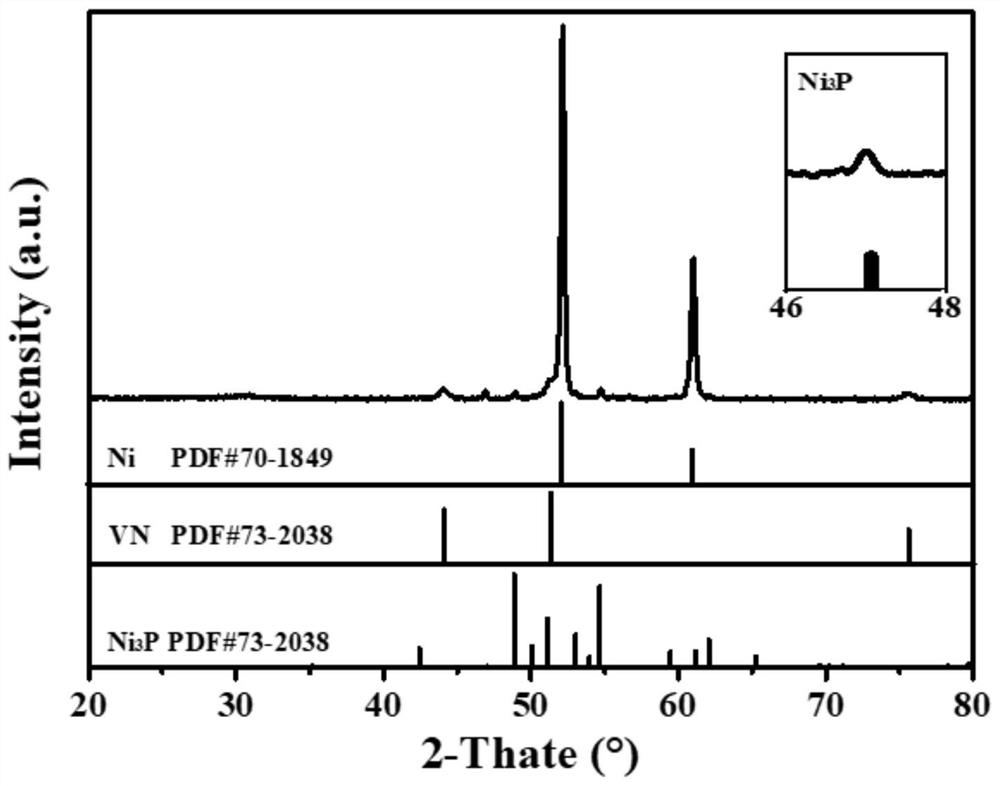

VN/Ni3P/Ni three-phase composite electrocatalyst as well as preparation method and application thereof

An electrocatalyst and reaction technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of single-phase catalyst activity limitation, complex preparation process, etc., and achieve low cost, high reaction yield, and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

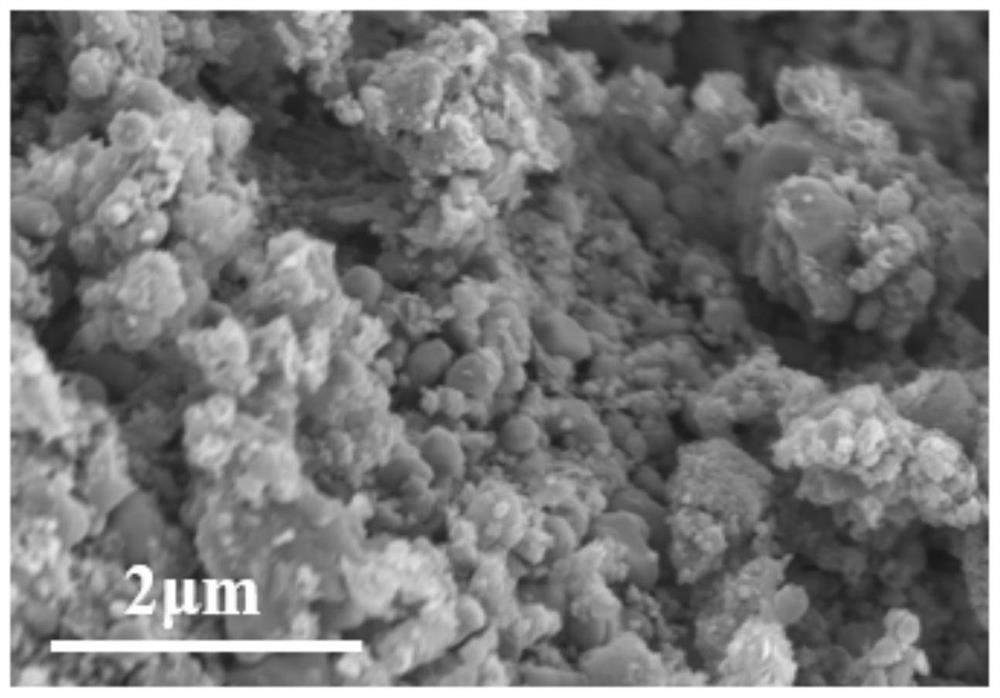

[0030] The invention provides a VN / Ni 3 The preparation method of P / Ni three-phase composite electrocatalyst specifically comprises the following steps:

[0031] Step 1: Dissolve nickel source, urea and ammonium fluoride in water at a molar ratio of (2-4):(23-26):(8-11), stir for 15-20 minutes to obtain a uniform solution, and then transfer to hydrothermal Place the still in an oven at 115-125°C to react for 15.5-16.5 hours to form a precipitate; the source of nickel is any one or more of nickel nitrate hexahydrate, nickel acetate hexahydrate and nickel chloride hexahydrate; The concentration is 0.044-0.058mol / L, and the filling ratio of the hydrothermal reactor is 70-80%;

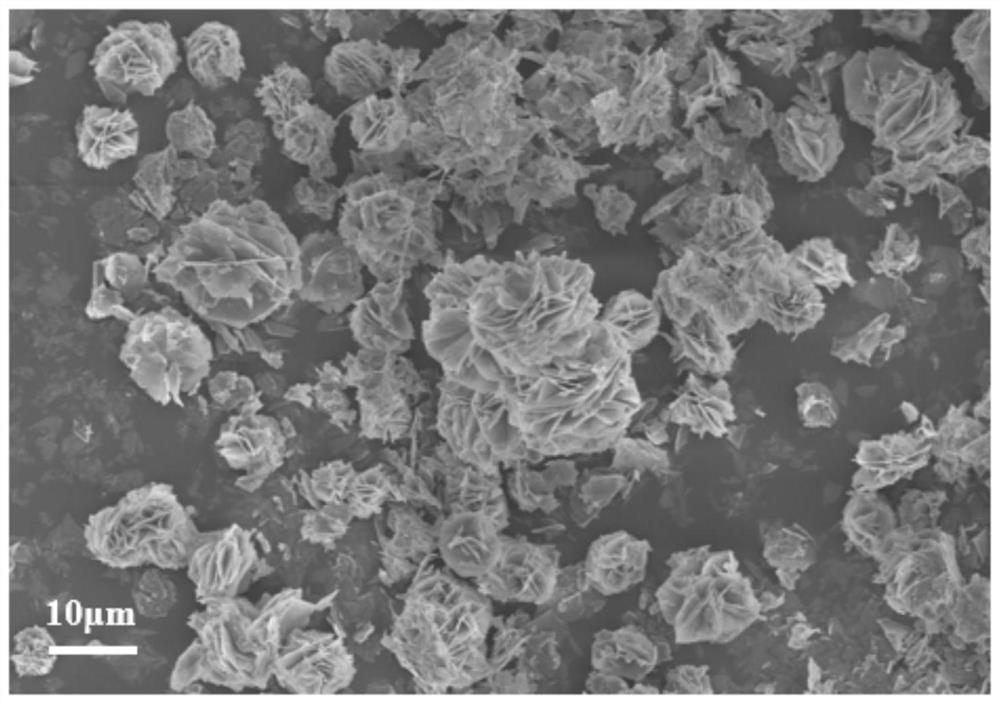

[0032] Step 2: After the reaction is completed and cooled naturally, the product is collected by suction filtration, washed alternately with water and ethanol for at least three times, and dried in a vacuum oven at 60°C for 6 hours to obtain a nickel hydroxide nanosheet precursor. Namely nickel hydroxide...

Embodiment 1

[0039] Step 1: Dissolve nickel nitrate hexahydrate, urea and ammonium fluoride in water at a molar ratio of 2:24:8, the concentration of nickel source is 0.045mol / L, the filling ratio of the hydrothermal reactor is 70%, and stir for 15 minutes A homogeneous solution was obtained, then transferred to a hydrothermal kettle and placed in an oven at 115°C for 15.5 hours to generate a precipitate;

[0040] Step 2: After the reaction is completed and cooled naturally, the product is collected by suction filtration, washed alternately with water and ethanol for at least three times, and dried in a vacuum oven at 60°C for 6 hours to obtain a nickel hydroxide nanosheet precursor;

[0041] Step 3: Weigh the nickel-containing hydroxide precursor, dicyandiamide, sodium hypophosphite and vanadium chloride with a mass ratio of 2:4:9:0.5, transfer the weighed sodium hypophosphite to a large porcelain boat and Concentrate on one end, and place the rest in an agate mortar for mechanical grindi...

Embodiment 2

[0044] Step 1: Dissolve nickel chloride hexahydrate, urea and ammonium fluoride in water at a molar ratio of 3:25:10, the concentration of nickel source is 0.050mol / L, the filling ratio of the hydrothermal reactor is 75%, stir A homogeneous solution was obtained in 18 minutes, then transferred to a hydrothermal kettle and placed in an oven at 120°C for 16 hours to generate a precipitate;

[0045] Step 2: After the reaction is completed and cooled naturally, the product is collected by suction filtration, washed alternately with water and ethanol for at least three times, and dried in a vacuum oven at 60°C for 6.0 hours to obtain a nickel hydroxide nanosheet precursor ;

[0046] Step 3: Weigh the nickel-containing hydroxide precursor, dicyandiamide, sodium hypophosphite and vanadium chloride with a mass ratio of 3:5:10:1, transfer the weighed sodium hypophosphite into a large porcelain boat and Concentrate on one end, and place the rest in an agate mortar for mechanical grindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com