Modified attapulgite loaded nano zero-valent iron composite material as well as preparation method and application thereof

A technology of nano-zero-valent iron and composite materials, applied in chemical instruments and methods, other chemical processes, restoration of contaminated soil, etc., can solve problems such as inability to exert dispersion effect, increase specific surface area, and limit loading efficiency, and achieve It is convenient for large-scale and industrial production and application, with fast removal rate and high removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of a modified attapulgite-loaded nano-zero-valent iron composite material

[0050] (1) First, put 5g of attapulgite in a muffle furnace and calcinate at 350°C for 1 hour to remove carbonate and structural water and increase its porosity. Then weigh 1 g of the above-mentioned attapulgite and 0.05 g of anionic surfactant SDS and disperse it in 40 ml of deionized water, sonicate for 0.5 h and then stir for 0.5 h.

[0051] (2) 5g FeCl 3 ·6H 2 O and 200ml of ethanol were added to the mixed solution of step (1), continued to sonicate for 0.5h and then stirred for 0.5h.

[0052] (3) Under nitrogen atmosphere, 25ml of 2wt% sodium borohydride aqueous solution was dropped into the mixed solution of step (2), and the dropping time was 0.5h. Rinse quickly three times with ethanol and deionized water respectively, centrifuge, and vacuum dry at 45°C for 24 hours to obtain the modified attapulgite-loaded nano-zero-valent iron composite material.

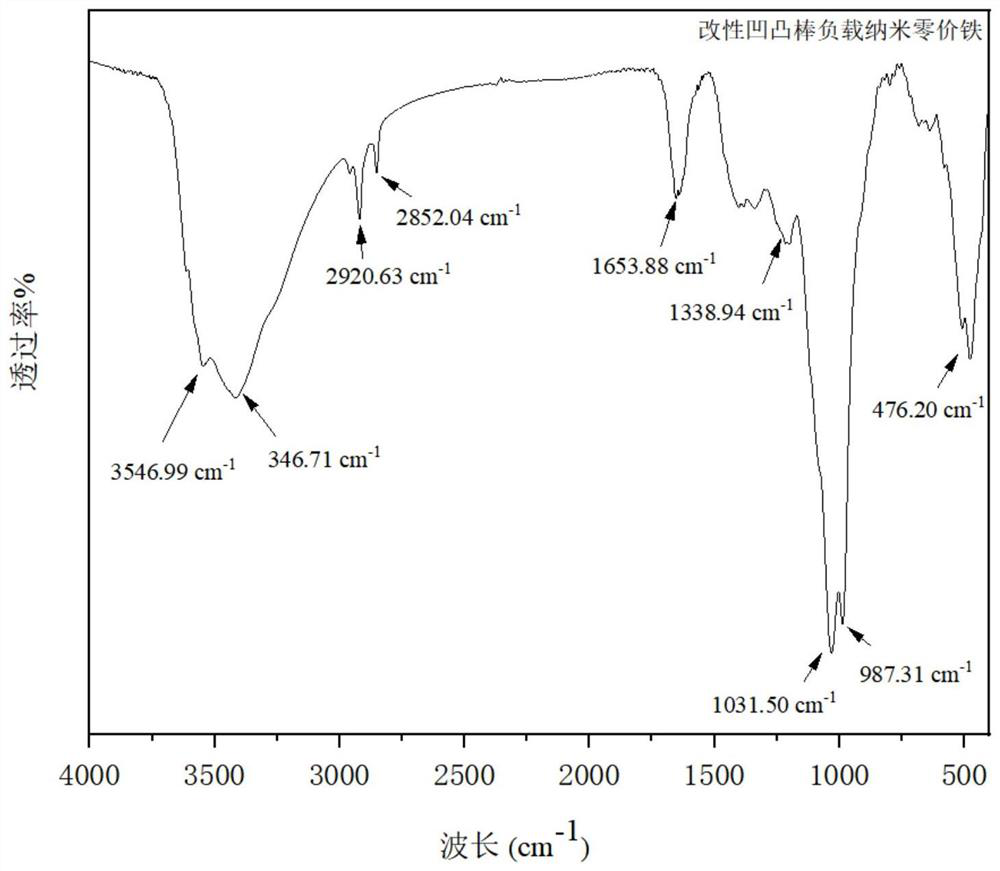

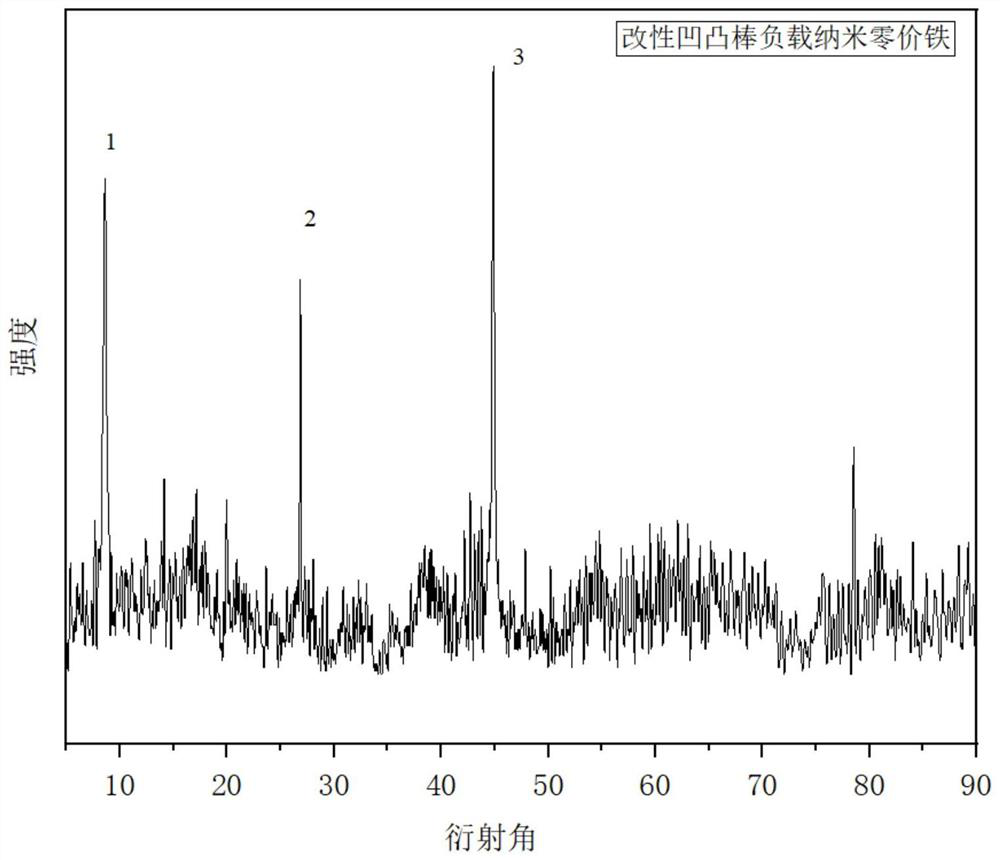

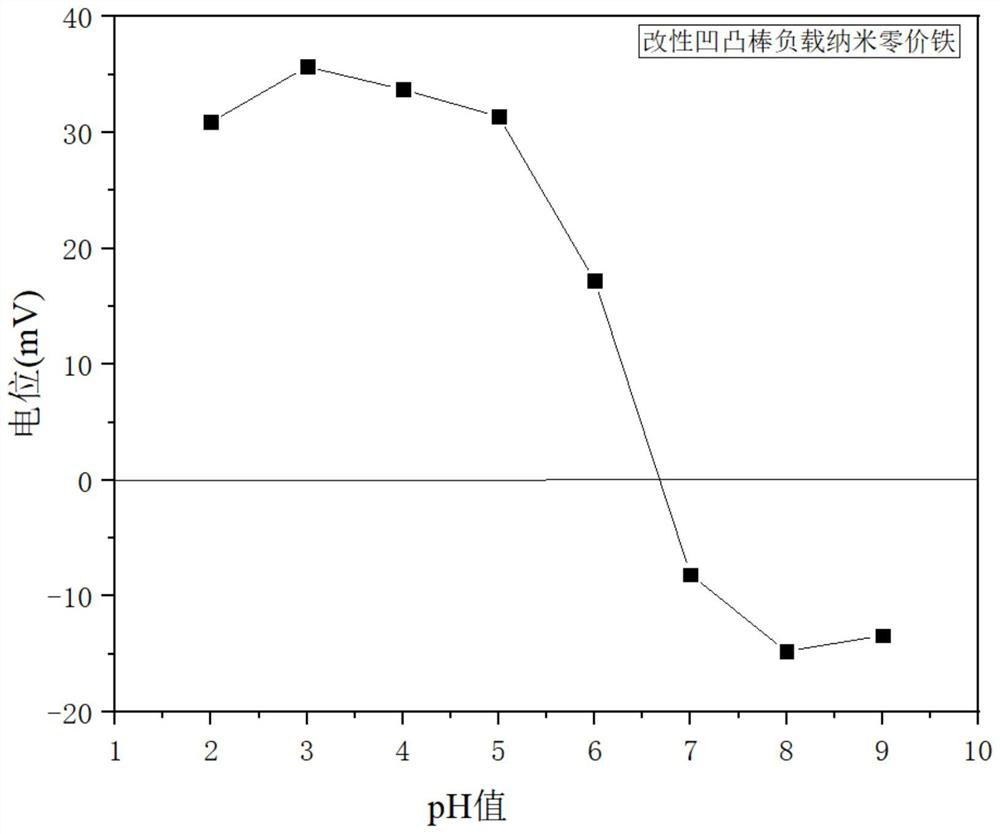

[0053] Using infrared...

Embodiment 2

[0055] Preparation of a modified attapulgite-loaded nano-zero-valent iron composite material

[0056] (1) First, put 5g of attapulgite in a muffle furnace and calcinate at 350°C for 1 hour to remove carbonate and structural water and increase its porosity. Then weigh 1 g of the attapulgite and 0.1 g of the anionic surfactant SDS and disperse it in 50 ml of deionized water, sonicate for 0.5 h and then stir for 0.5 h.

[0057] (2) 4.5g FeCl 3 ·6H 2 O and 150ml of ethanol were added to the mixed solution of step (1), and the ultrasonic wave was continued for 0.5h and then stirred for 0.5h.

[0058] (3) Under nitrogen atmosphere, 25ml of 2wt% sodium borohydride aqueous solution was dropped into the mixed solution of step (2), and the dropping time was 1 h. Rinse quickly three times with ethanol and deionized water respectively, centrifuge, and vacuum dry at 45°C for 24 hours to obtain the modified attapulgite-loaded nano-zero-valent iron composite material.

[0059] Use infrar...

Embodiment 3

[0061] Preparation of a modified attapulgite-loaded nano-zero-valent iron composite material

[0062] (1) First, put 5g of attapulgite in a muffle furnace and calcinate at 350°C for 1 hour to remove carbonate and structural water and increase its porosity. Then weigh 1 g of the above-mentioned attapulgite and 0.05 g of SDS and disperse it in 50 ml of deionized water, sonicate for 0.5 h and then stir for 0.5 h.

[0063] (2) 2.5g FeCl 3 ·6H 2 O and 200ml of ethanol were added to the mixed solution of step (1), continued to sonicate for 0.5h and then stirred for 0.5h.

[0064] (3) Under nitrogen atmosphere, 15ml of 2.5wt% sodium borohydride aqueous solution was dropped into the mixed solution in step (2), and the dropping time was 0.5h. Rinse quickly three times with ethanol and deionized water respectively, centrifuge, and vacuum dry at 45°C for 24 hours to obtain the modified attapulgite-loaded nano-zero-valent iron composite material.

[0065] Use infrared spectroscopy to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com