Graphdiyne composite material for fuel preparation through photocatalytic CO2 reduction and preparation method thereof

A composite material and graphyne technology, applied in the field of photocatalytic CO2 reduction to fuel, can solve the problems of photocatalytic reduction efficiency and poor selectivity, and achieve the effects of enhancing photocatalytic efficiency, improving photocatalytic reduction efficiency, and promoting separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

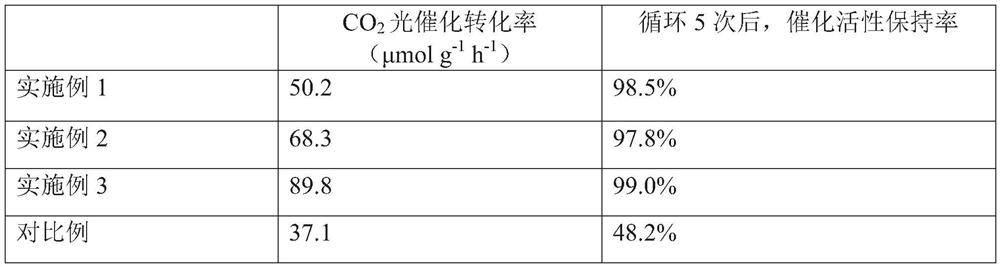

Embodiment 1

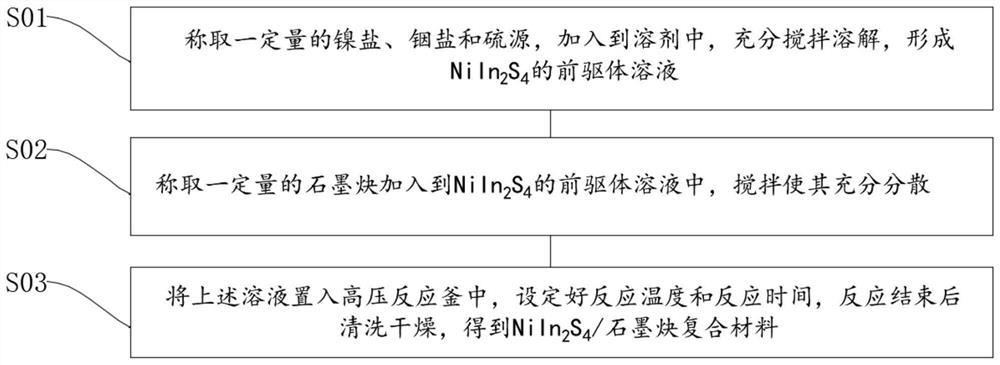

[0032] S01, take by weighing 1.0mmol of nickel chloride hexahydrate, 2.0mmol of indium trichloride, and 8.0mmol of thiourea, and add them to 70ml of N,N-dimethylformamide and ethylene glycol (volume ratio 1:1 ) in a mixed solvent, fully stirred and dissolved to form Niln 2 S 4 The precursor solution;

[0033] S02, weigh 0.2g graphdiyne, add to Niln 2 S 4 In the precursor solution, stir to make it fully dispersed;

[0034] S03, put the above solution into a high-pressure reactor, the reaction temperature is 200°C, the reaction time is 8h, after the reaction is completed, it is washed and dried to obtain Niln 2 S 4 / graphyne.

Embodiment 2

[0036] S01, take by weighing 1.0mmol of nickel chloride hexahydrate, 2.0mmol of indium trichloride, and 8.0mmol of thiourea, and add them to 70ml of N,N-dimethylformamide and ethylene glycol (volume ratio 1:1 ) in a mixed solvent, fully stirred and dissolved to form Niln 2 S 4 The precursor solution;

[0037] S02. Weigh 0.2g of nitrogen-doped graphyne and add to Niln 2 S 4 In the precursor solution, stir to make it fully dispersed;

[0038] S03, put the above solution into a high-pressure reactor, the reaction temperature is 200°C, the reaction time is 8h, after the reaction is completed, it is washed and dried to obtain Niln 2 S 4 / Nitrogen-doped graphyne.

Embodiment 3

[0040] S01, take by weighing 1.0mmol of nickel chloride hexahydrate, 2.0mmol of indium trichloride, and 8.0mmol of thiourea, and add them to 70ml of N,N-dimethylformamide and ethylene glycol (volume ratio 1:1 ) in a mixed solvent, fully stirred and dissolved to form Niln 2 S 4 The precursor solution;

[0041] S02. Weigh 0.2g of boron-doped graphyne and add to Niln 2 S 4 In the precursor solution, stir to make it fully dispersed;

[0042] S03, put the above solution into a high-pressure reactor, the reaction temperature is 200°C, the reaction time is 8h, after the reaction is completed, it is washed and dried to obtain Ni ln 2 S 4 / Boron-doped graphyne.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com