Method for preparing phosphorus and magnesium doped polyaluminum chloride flocculant by utilizing secondary aluminum ash

A technology of polyaluminum chloride and flocculant, which is applied in the field of resource utilization of hazardous waste, can solve the problems of poor performance of PAC products, high content of harmful impurities, and restrictions on the application of aluminum ash, and achieve full utilization, efficient utilization, and high adsorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

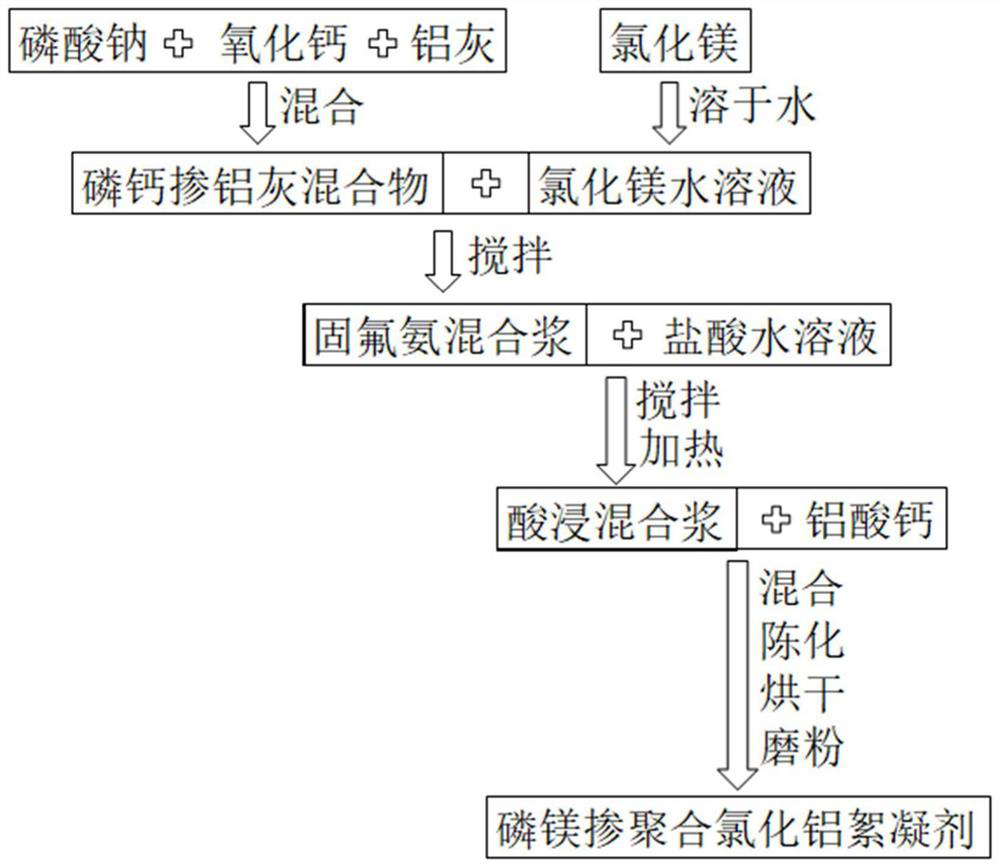

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Influence of the mass ratio of sodium phosphate, calcium oxide and aluminum ash on the performance of the prepared phosphorus and magnesium doped polyaluminum chloride flocculant

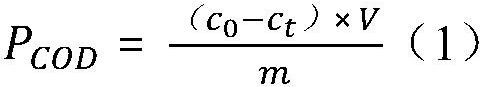

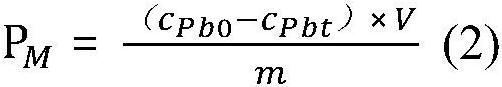

[0026] According to the mass ratio 7.5:1.0:100, 7.5:1.5:100, 7.5:2.0:100, 5:2.5:100, 5.5:2.5:100, 6.5:2.5:100, 7.5:2.5:100, 12.5:2.5:100 , 17.5: 2.5: 100, 7.5: 5: 100, 12.5: 5: 100, 17.5: 5: 100, 7.5: 7.5: 100, 12.5: 7.5: 100, 17.5: 7.5: 100, 18.5: 7.5: 100, 19.5 : 7.5: 100, 20: 7.5: 100, 17.5: 8.5: 100, 17.5: 9.5: 100, 17.5: 10: 100 were weighed and mixed with sodium phosphate, calcium oxide, and aluminum ash to obtain 21 groups of phosphorus-calcium-aluminum ash mixture . Weigh magnesium chloride and dissolve it in water to prepare a magnesium chloride aqueous solution with a concentration of 0.025 g / mL. According to the liquid-solid ratio of 0.5:1mL / g, mix the magnesium chloride aqueous solution and the phosphorus-calcium-aluminum ash mixture, and stir for 1 hour under sealed c...

Embodiment 2

[0035] Example 2 Influence of the concentration of magnesium chloride aqueous solution on the performance of the prepared phosphorus and magnesium mixed with polyaluminum chloride flocculant

[0036] The sodium phosphate, calcium oxide, and aluminum ash were weighed and mixed according to the mass ratio of 17.5:7.5:100 to obtain a phosphorus-calcium-aluminum ash mixture. Weigh magnesium chloride and dissolve it in water to prepare concentrations of 0.01g / mL, 0.015g / mL, 0.02g / mL, 0.025g / mL, 0.05g / mL, 0.075g / mL, 0.08g / mL, 0.085g / mL , 0.09g / mL magnesium chloride aqueous solution, a total of nine groups. According to the liquid-solid ratio of 1.5:1mL / g, the aqueous solution of magnesium chloride and the mixture of phosphorus, calcium and aluminum mixed with ash were mixed, and stirred for 2.5 hours under sealed conditions to obtain nine groups of solid fluorine and ammonia mixed slurry. Add hydrochloric acid to water to prepare an aqueous hydrochloric acid solution with a mass fr...

Embodiment 3

[0043] Example 3 The effect of the amount of calcium aluminate added on the performance of the prepared phosphorus and magnesium doped polyaluminum chloride flocculant

[0044] The sodium phosphate, calcium oxide, and aluminum ash were weighed and mixed according to the mass ratio of 17.5:7.5:100 to obtain a phosphorus-calcium-aluminum ash mixture. Weigh magnesium chloride and dissolve it in water to prepare a magnesium chloride aqueous solution with a concentration of 0.075 g / mL. According to the liquid-solid ratio of 2.5:1mL:g, mix the magnesium chloride aqueous solution and the phosphorus-calcium-aluminum ash mixture, and stir for 4 hours under sealed conditions to obtain the fluoride-ammonia mixed slurry. Add hydrochloric acid into water to prepare an aqueous hydrochloric acid solution with a mass fraction of 30%. According to the volume ratio of hydrochloric acid aqueous solution and fluoroammonia mixed slurry of 4:1, mix the volume ratio of hydrochloric acid aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com