Colloid ink and method for constructing ordered nanoparticle single-layer film through ink-jet printing

A nanoparticle and inorganic nanoparticle technology, applied in the field of nanomaterials, can solve the problems of low utilization rate of raw materials, easy wrinkling in the transfer process, low surface tension, etc., and achieve simple and fast film formation process, easy large-scale preparation, and raw material utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

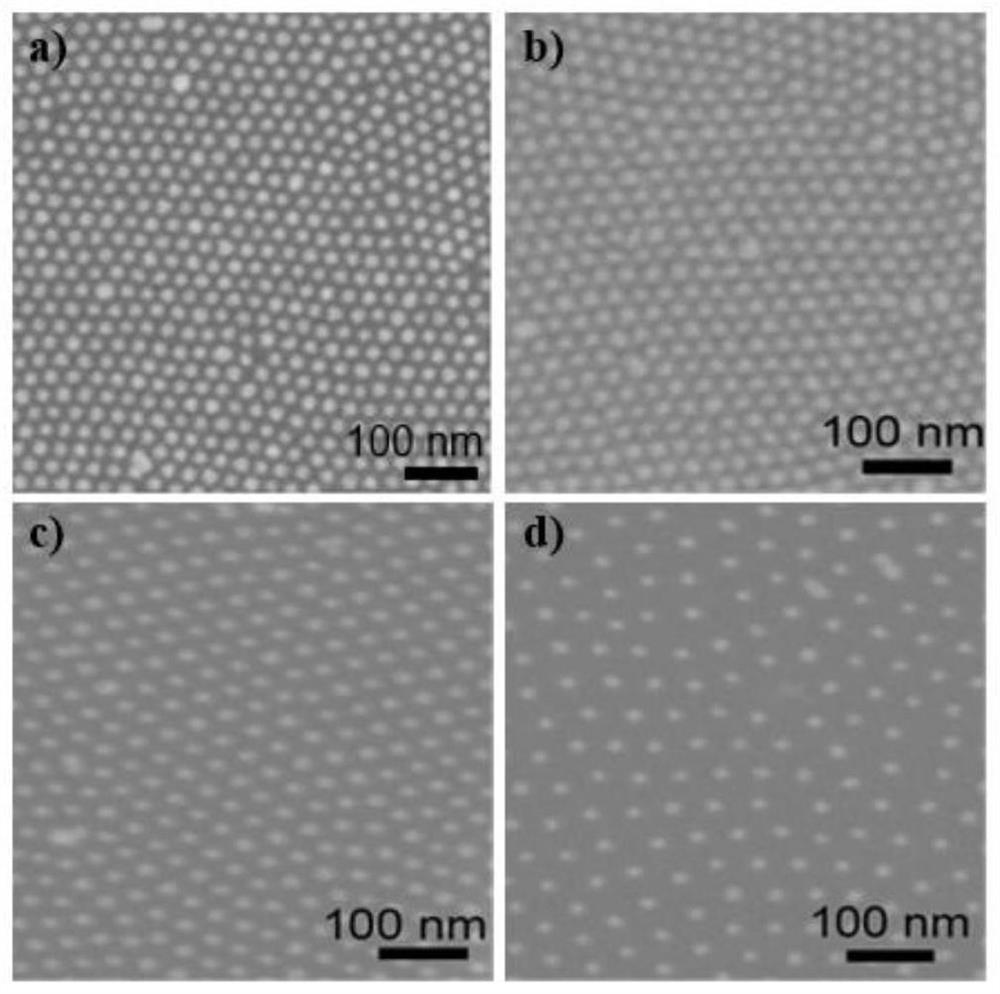

[0036] The preparation of polystyrene-grafted gold nanoparticle monolayer film by inkjet printing includes the following steps:

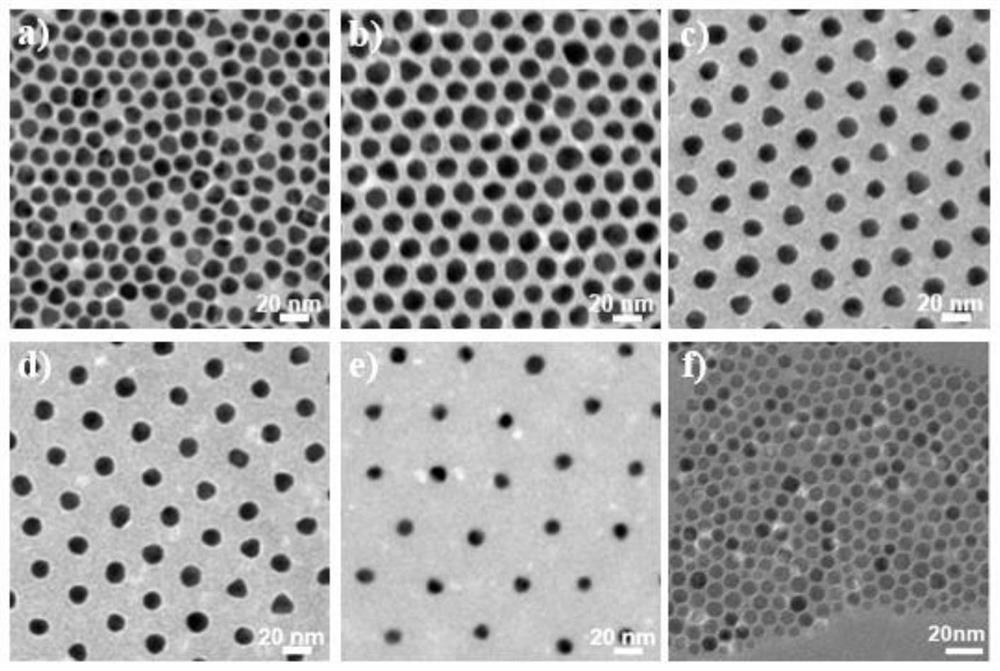

[0037] (1) Preparation of polystyrene-grafted gold nanoparticles: Using thiol-terminated oil-soluble polymer polystyrene (PS), the spherical gold nanoparticles obtained by hydrothermal method were modified by ligand exchange method. Wash to remove excess free polymer, dry and weigh for use. The molecular weight of the polymer used is 2000 g / mol, the solvent used for cleaning is dichloromethane, and the size of the gold nanoparticles is 15 nm.

[0038] (2) Preparation of ink: The polystyrene-grafted gold nanoparticles dried in step (1) were dispersed into the cyclohexanone solution, and dispersed by ultrasonic for 3 minutes, wherein the nanoparticle concentration was 75 mg / ml.

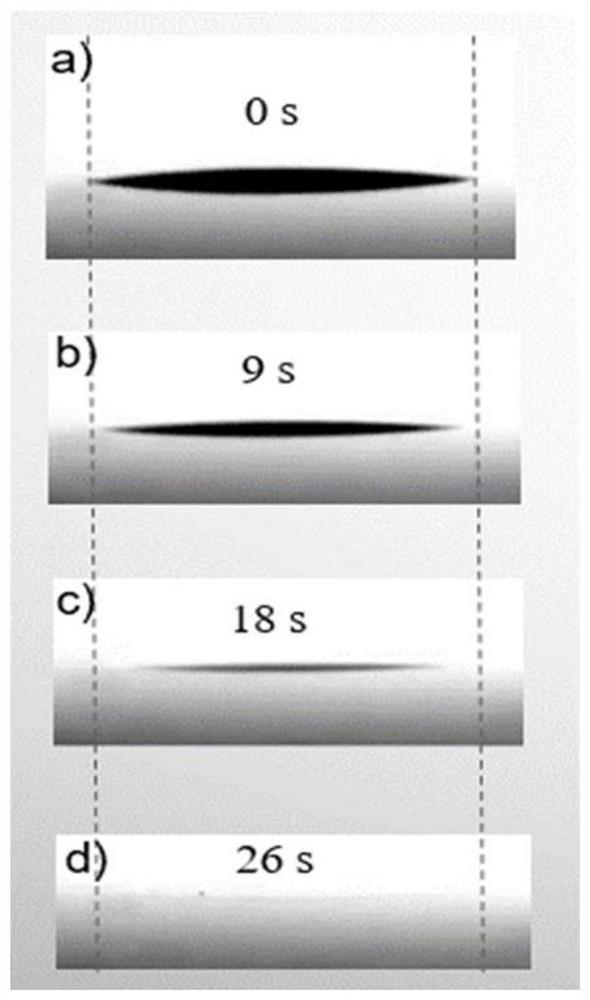

[0039] (3) Inkjet printing: using a direct-writing inkjet printer, the inner diameter of the nozzle outlet is 50 μm, the printing voltage is 2.5V, the printing line spacing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com