Method for co-processing pellet desulfurized fly ash by wet desulphurization system

A wet desulfurization and co-processing technology, applied in the field of flue gas desulfurization, can solve the problems of increasing the load of wastewater treatment and the difficulty of dewatering sludge treatment, affecting the smooth running of the system, and deepening the color of gypsum by-products, so as to improve the quality of recycled water and absorb Effects of tower slurry environment, mitigation of foaming and overflow conditions, and avoidance of cyclic enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The pellet desulfurization ash in this example comes from the dry / semi-dry flue gas desulfurization device in the pellet preparation process. The flue gas desulfurization process is a circulating fluidized bed. The sample is loose and light reddish brown. The main components are as follows : CaSO 3 1 / 2H 2 O: 23.46%, CaSO 4 2H 2 O: 3.38%, CaCO 3 : 18.56%, Ca(OH) 2 : 6.19%, CaCl 2 : 0.83%, SiO 2 : 5.0%, Al 2 o 3 : 3.5%, Fe 2 o 3 : 4.2%, Cl: 2.8%, by weight percentage.

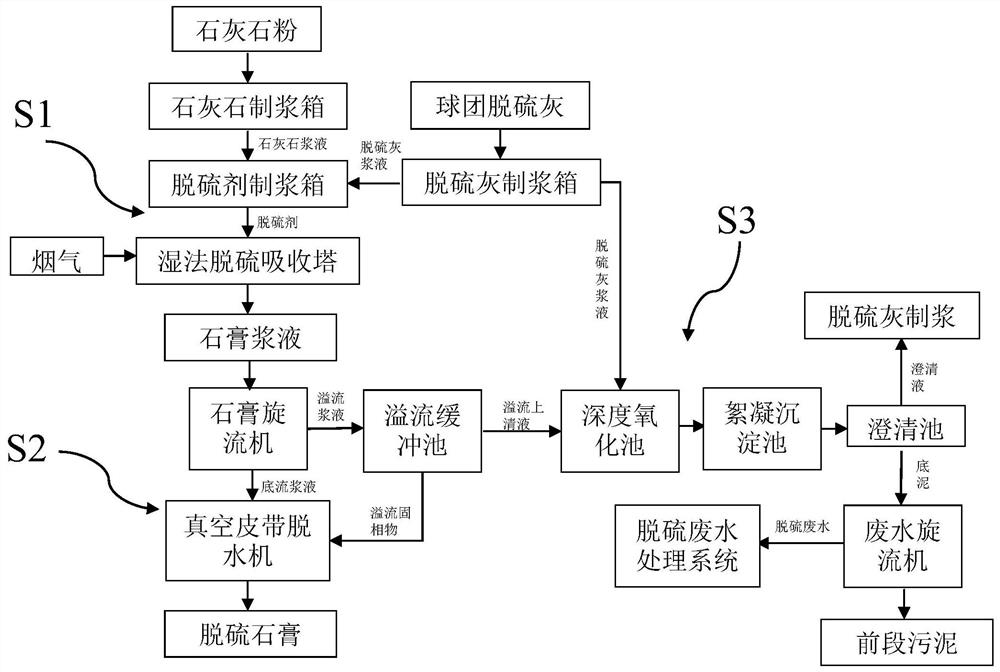

[0043] The method for the wet desulfurization system of this embodiment to co-process pelletized desulfurized ash, the specific steps are as follows: the desulfurized ash slurry is formed after the pelletized desulfurized ash is pulped, and a part of the desulfurized ash slurry is 1 with the existing limestone slurry according to the solid phase mass ratio : 0.5 mixed as a desulfurizer, enter the spray tower, and mix with SO in the flue gas in the slurry pool 2 After absorption, neutralization,...

Embodiment 2

[0050] The pellet desulfurization ash in this example comes from a dry / semi-dry flue gas desulfurization device in the pellet preparation process. The flue gas desulfurization process is a rotary spraying process. The sample is loose and light grayish brown. The main components are as follows: CaSO 3 1 / 2H 2 O: 42.78%, CaSO 4 2H 2 O: 4.05%, CaCO 3 : 3.83%, Ca(OH) 2 : 1.68%, CaCl 2 : 0.98%, SiO 2 : 2.0%, Al 2 o 3 : 1.5%, Fe 2 o 3 : 2.0%, Cl: 3.85%, by weight percentage.

[0051] The method for the wet desulfurization system of this embodiment to co-process pelletized desulfurized ash, the specific steps are as follows: the desulfurized ash slurry is formed after the pelletized desulfurized ash is pulped, and a part of the desulfurized ash slurry is 1 with the existing limestone slurry according to the solid phase mass ratio : 0.5 mixed as a desulfurizer, enter the spray tower, and mix with SO in the flue gas in the slurry pool 2 After absorption, neutralization, oxid...

Embodiment 3

[0058] The pellet desulfurization ash in this example comes from a dry / semi-dry flue gas desulfurization device in the pellet preparation process. The flue gas desulfurization process is a rotary spraying process. The sample is loose and light grayish brown. The main components are as follows: CaSO 3 1 / 2H 2 O: 40.85%, CaSO 4 2H 2 O: 11.52%, CaCO 3 : 5.78%, Ca(OH) 2 : 4.65%, CaCl 2 : 2.55%, SiO 2 : 1.5%, Al 2 o 3 : 1.2%, Fe 2 o 3 : 3.5%, Cl: 1.52%, by weight percentage.

[0059] The method for the wet desulfurization system of this embodiment to co-process pelletized desulfurized ash, the specific steps are as follows: the desulfurized ash slurry is formed after the pelletized desulfurized ash is pulped, and a part of the desulfurized ash slurry is 1 with the existing limestone slurry according to the solid phase mass ratio : 5 mixed as a desulfurizer, enter the spray tower, and mix with SO in the flue gas in the slurry pool 2 After absorption, neutralization, oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com