Flotation separation method for talc and copper sulphide

A technology of copper sulfide and talc, applied in flotation, solid separation, etc., can solve the problems of unstable index, easy to bring in impurity ions, high cost, etc., to increase the difference in floatability, reduce surface hydrophobicity, and achieve good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

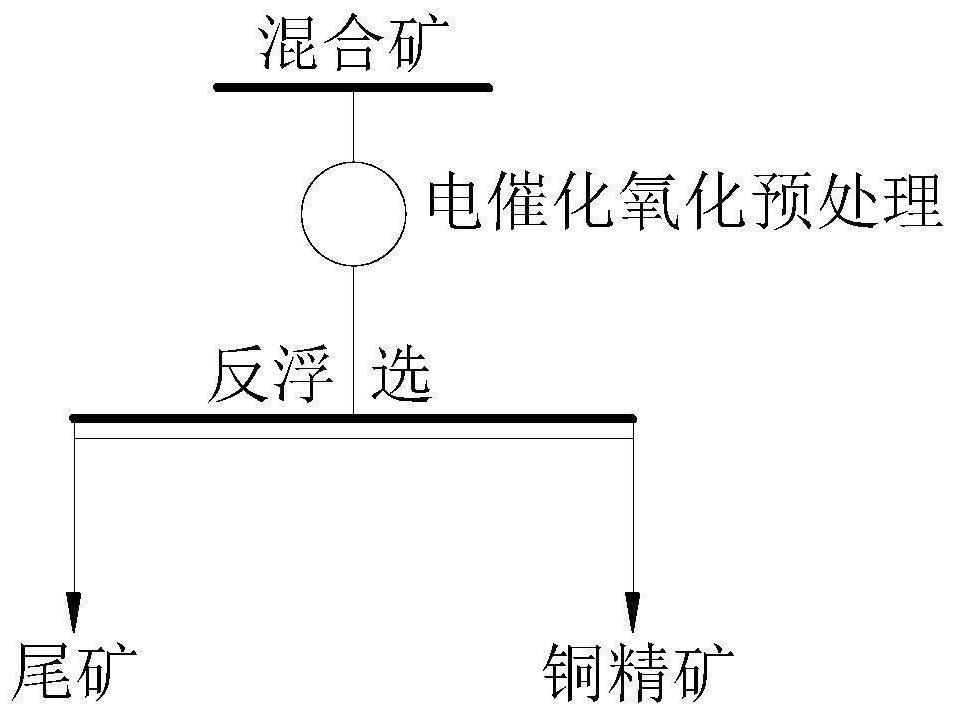

[0070] This embodiment provides a method for the flotation separation of talc and copper sulfide. The mixed ore of talc and chalcopyrite in this example is an artificial mixed ore, prepared from pure minerals of chalcopyrite and talc in a mass ratio of 1:3. The fineness of the mixed concentrate is -0.074mm, accounting for 88.14%, and the copper grade in the mixed ore of talc and chalcopyrite is 8.70%.

[0071] Step 1: separate the cathode graphite sheet and the anode Ti / SnO 2 - Insert the Sb plate into the electrolytic cell, and add 0.05mol / L potassium nitrate solution to it, add talc and chalcopyrite mixed ore to the electrolytic cell while stirring, and control the pulp concentration to 5.0%;

[0072] Step 2: After stirring evenly, continue to stir, turn on the constant current source, apply a current of 0.7A to the electrolytic cell, and treat with a constant current for 20 minutes to obtain the pretreated mixed pulp;

[0073] Step 3: transfer the mixed pulp to the flotat...

Embodiment 2

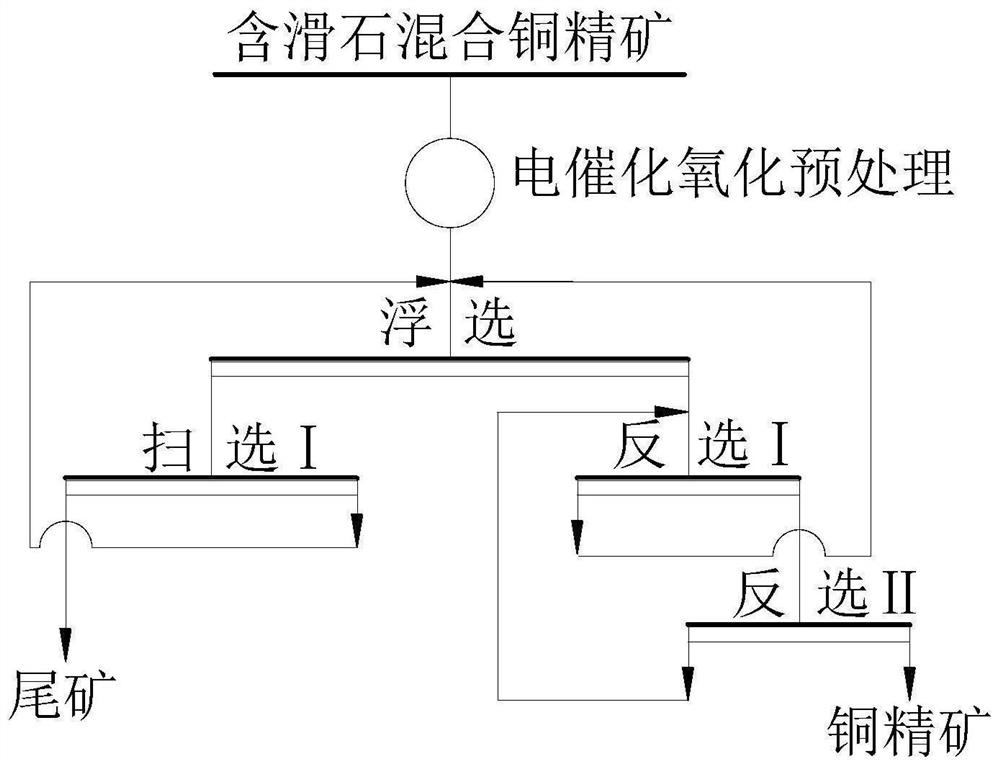

[0077] This embodiment provides a method for the flotation separation of talc and copper sulfide.

[0078] In this embodiment, the talc-containing mixed copper concentrate produced by the conventional flotation process of a large porphyry copper mine is adopted, and the copper grade is 16.72%. The metal minerals in the talc-containing mixed copper concentrate are mainly chalcopyrite, chalcocite, pyrite, etc.; the gangue minerals are mainly talc, serpentine, quartz, mica, potassium feldspar, etc. Among them, the chalcopyrite content is 46.77%, and the talc content is 26.73%. The copper concentrate particle size -0.074mm accounts for 83.42%.

[0079] Step 1: separate the cathode copper sheet and the anode Pt-WO 3Insert the plate into the electrolytic cell, and add 0.1mol / L sodium nitrate solution to it, add talc-containing mixed copper concentrate to the electrolytic cell while stirring, and control the pulp concentration to 2.5%;

[0080] Step 2: After stirring evenly, conti...

Embodiment 3

[0085] This embodiment provides a method for the flotation separation of talc and copper sulfide.

[0086] In this example, a talc-containing mixed copper concentrate produced by a difficult-to-select polymetallic copper sulfide beneficiation plant in Yunnan through a process of first roughing, first mixing, third refining, second sweeping, mixing and refining, and then grinding to give priority to floating copper. The grade of copper in the talc-containing mixed copper concentrate is 14.65%, the content of chalcopyrite is 41.42%, and the content of talc is 21.51%. The magnesium oxide content exceeds the national quality standard requirements for fifth-grade copper concentrate. In addition, the particle size of the copper concentrate is -0.074mm, accounting for 79.88%.

[0087] Step 1: separate the cathode stainless steel sheet and the anode Ti / IrO 2 -Ta 2 o 5 Insert the plate into the electrolytic cell, and add 0.15mol / L sodium nitrate solution to it, add talc-containing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com