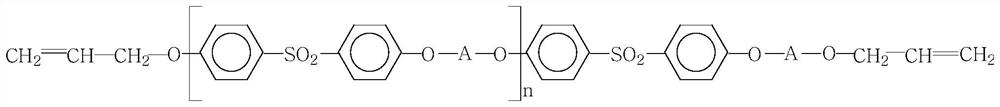

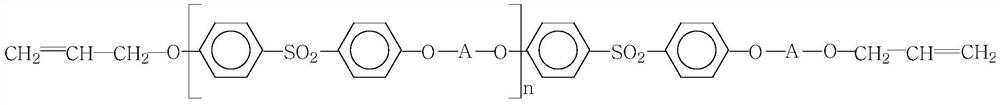

Allyl-terminated arylsulfone ether polymer and preparation method thereof

A technology of terminal allyl aryl sulfone ether and polymer, which is applied in the field of allyl terminal aryl sulfone ether polymer and its preparation, can solve the problems of high material brittleness and hinder the practical application of double horse resin, and achieve high temperature resistance Good chemical reactivity, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

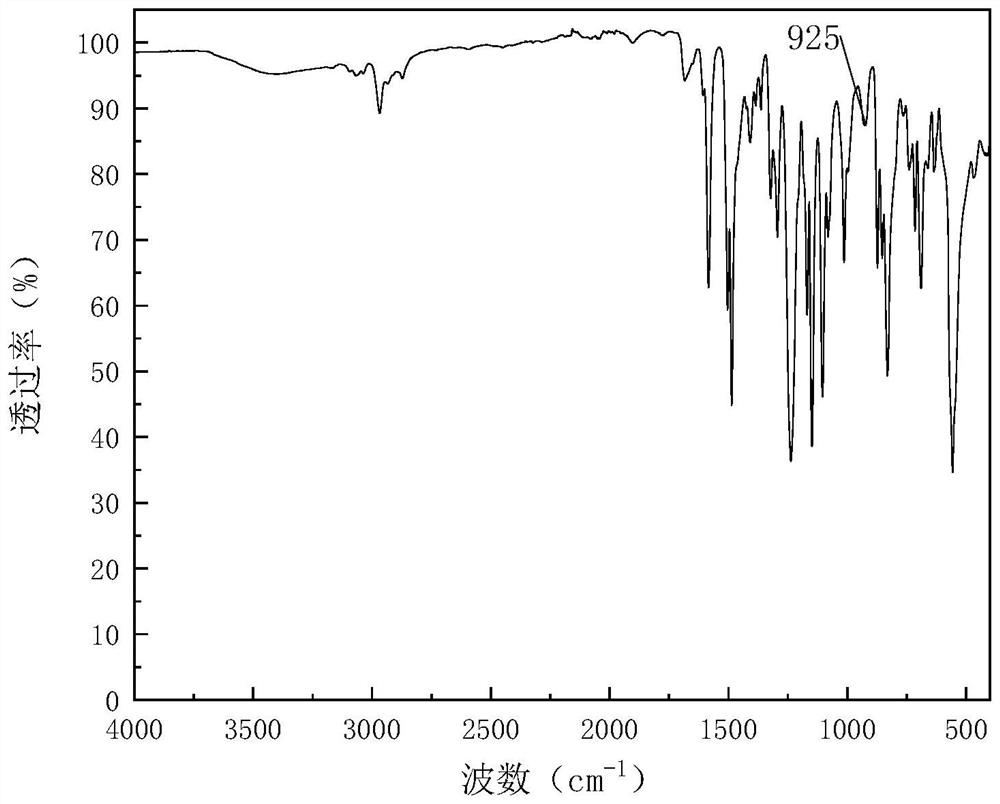

Embodiment 1

[0042] 68.4 grams (0.3 moles) of bisphenol A, 57.4 grams (0.2 moles) of 4,4'-dichlorodiphenyl sulfone (DCDS), 1520.0 grams of N-methyl-2-pyrrolidone (NMP), 152.0 grams of toluene and 41.4 Put gram (0.3 moles) of potassium carbonate into the reaction kettle, heat and reflux at 100°C-200°C for 5 hours, then recycle toluene (recycle), cool to below 60°C, add 229.5 grams (3.0 moles) of alkene Propyl chloride (AC) and 5.0 grams of tetrabutylammonium chloride, continue to heat and reflux for 5 hours, after the reaction finishes, filter desalination, concentrate under reduced pressure, reclaim organic solvent and excess allyl chloride (AC), and recycle Use, the concentrated mother liquor is precipitated rapidly in 3344 grams of water, filters, washes 2-5 times with deionized water, vacuum-dries in the temperature range of 25 ℃-180 ℃ 2 hours, obtains 118.6 gram of solid products (theoretical output is 119.2 gram ), which is a terminal allyl aryl sulfone ether polymer, denoted as AP-1,...

Embodiment 2

[0044] 235.2 grams (0.7 moles) of bisphenol AF, 45.6 grams (0.2 moles) of bisphenol A, 229.6 grams (0.8 moles) of 4,4'-dichlorodiphenyl sulfone (DCDS), 600.0 grams of N-methyl-2- Pyrrolidone (NMP), 140.0 grams of dimethyl sulfoxide, 200.0 grams of toluene, 500.0 grams of xylene, 41.4 grams (0.3 moles) of potassium carbonate and 153.7 grams (1.45 moles) of sodium carbonate were put into the reaction kettle, at 100°C- After heating at reflux at 200°C for 20 hours to separate water, recover toluene and xylene (recycle), cool to below 60°C, add 107.1 grams (1.4 moles) of allyl chloride (AC) and 8.0 grams of tetrabutyl bromide Ammonium, continue to heat and reflux for 8 hours, after the reaction finishes, filter desalination, concentrate under reduced pressure, reclaim organic solvent and excessive allyl chloride (AC), recycle, the mother liquor after concentrating is in 11000 grams of water and 1780 grams of methyl alcohol Rapid precipitation in the mixed precipitant, filtration, ...

Embodiment 3

[0046] 33.6 grams (0.1 moles) of bisphenol AF, 12.4 grams (0.1 moles) of o-methylhydroquinone, 28.7 grams (0.1 moles) of 4,4'-dichlorodiphenyl sulfone (DCDS), 500 grams of N-methyl Base-2-pyrrolidone (NMP), 80.5 grams of toluene and 41.4 grams (0.3 moles) of potassium carbonate were put into the reaction kettle, and after heating and reflux at 100° C. to 200° C. for 20 hours, the toluene was reclaimed (recycled), Cool to below 60°C, add 122.4 grams (1.6 moles) of allyl chloride (AC) and 4.0 grams of tetrabutylammonium chloride, continue to heat and reflux for 8 hours, after the reaction is completed, filter to remove salt, concentrate under reduced pressure, and recover organic The solvent and excess allyl chloride (AC) are recycled, and the concentrated mother liquor is quickly precipitated in 3483 grams of water, filtered, washed with deionized water for 2-5 times, and vacuum-dried within the temperature range of 25°C-180°C After 8 hours, 74.7 g of solid product was obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap