System and method for preparing refined xylose and fermentable sugar from corn straw

A technology for fermenting corn stalks and sugar, applied in chemical instruments and methods, fermentation, preparation of sugar derivatives, etc., can solve problems such as high cost, high energy consumption, and reduced xylose yield, so as to save time and cost, increase The loss of xylose and the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0041] Embodiment 2 acid hydrolysis

[0042] In this example, 10 groups of acid hydrolysis experiments were carried out on the alkali-treated corn stalk residue, and the specific implementation scheme and experimental result data are shown in Table 4 and Table 5 respectively.

[0043] The acid hydrolysis experiment was carried out on the corn stalk residue after being treated with the optimal alkali treatment conditions. When the acid concentration was 2%, the maximum xylose yield was 80.64%. At this time, the hemicellulose content in the acid hydrolysis residue was 3.51%, and the cellulose The content is 64.70%.

[0044] Table 4 Acid hydrolysis results of alkali-treated corn stalk residue

[0045]

[0046] Other reaction conditions: solid-to-liquid ratio 1:8, reaction temperature 125°C, reaction time 140min. The hemicellulose content of corn stalks is 21.50%, and the average hemicellulose content in the straw residue after alkali treatment is 23.25%.

[0047] As can be ...

Embodiment 3

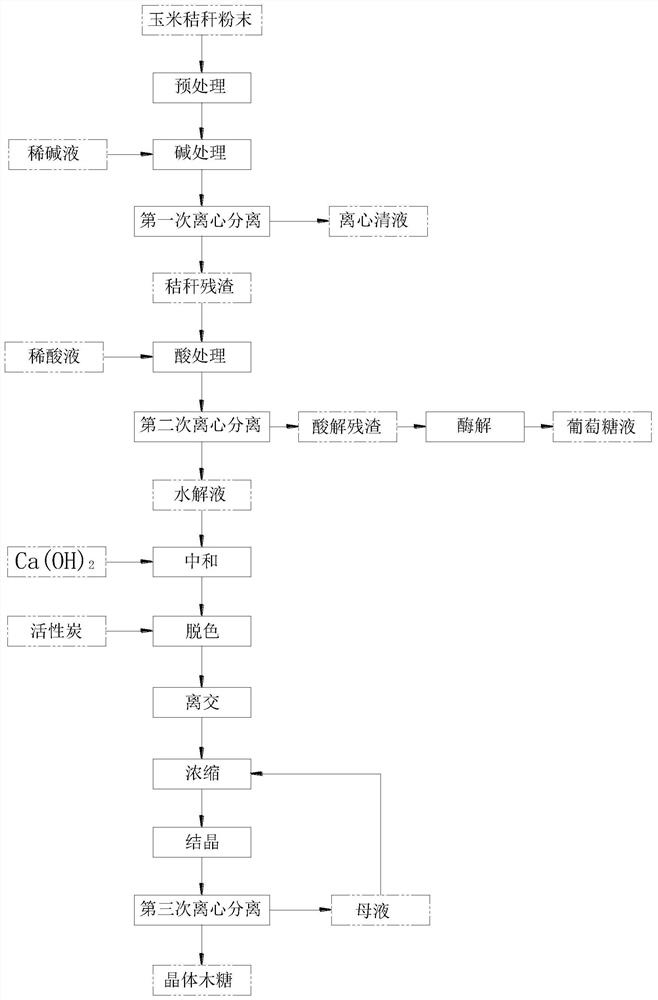

[0052] Example 3 Preparation of Refined Xylose

[0053] In this embodiment, after the hydrolyzed solution undergoes neutralization, decolorization, one-time separation, and concentrated crystallization processes in sequence, xylose crystals are obtained, and the purity of xylose is above 99.5%. Based on the xylose content in the hydrolyzate, the yield of crystal xylose is 26.5%. Throughout the refining process, the xylose crystallization mother liquor will be repeatedly concentrated and crystallized for use.

[0054] The decolorization and separation process will cause some loss of xylose. Compared with the four separations (xylose loss rate > 17%) adopted in the prior art, the embodiment of the present invention uses one separation to reduce the xylose loss rate. Nearly 1% (xylose loss <16.2%).

[0055] Compared with the existing refining process that adopts four separations, because the previous alkali treatment has removed most of the non-xylose impurities that are easily...

Embodiment 4

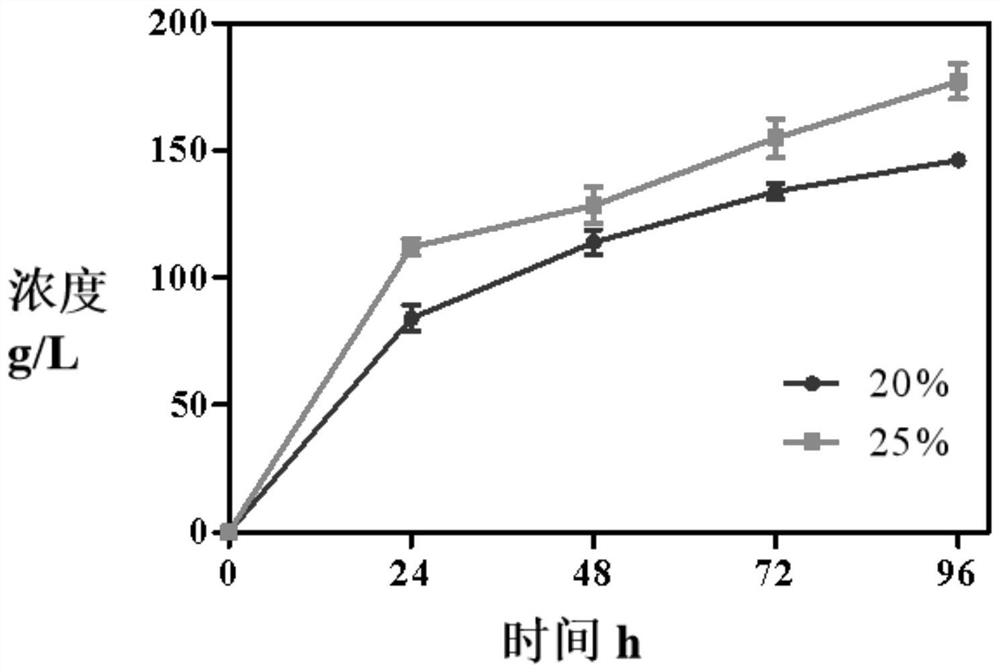

[0058] Embodiment 4 Acid hydrolysis residue prepares glucose

[0059] The acid hydrolysis residue obtained after dilute alkali-dilute acid treatment is added to Novozymes Ctec2 cellulase for enzymolysis. The glucose concentration of 20% dry basis enzymatic hydrolysis can reach 146g / L, and the concentration of 25% dry basis enzymatic hydrolysis glucose can reach 177g / L, obtained as image 3 The corresponding curves of enzymatic hydrolysis glucose concentration and enzymatic hydrolysis time are shown. In the patent with publication number CN112522347A, the test parameters for preparing enzymatic glucose are disclosed as follows: 20% dry basis, glucose concentration 120g / L; 25% dry basis, glucose concentration 140g / L. Therefore, the comparison of the test data shows that the glucose concentration prepared by the method of the present invention is nearly 20% higher than that of the prior art method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com