Cerium oxide loaded calcium peroxide composite material, water body disinfectant and disinfection method

A technology of calcium peroxide and composite materials, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, disinfectant, etc., can solve the problem of unclear evaluation of sterilization types and evaluation of sterilization and detoxification effects Incomplete, unclear evaluation of the bactericidal action mechanism, etc., to achieve a significant killing effect, easy to store, and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

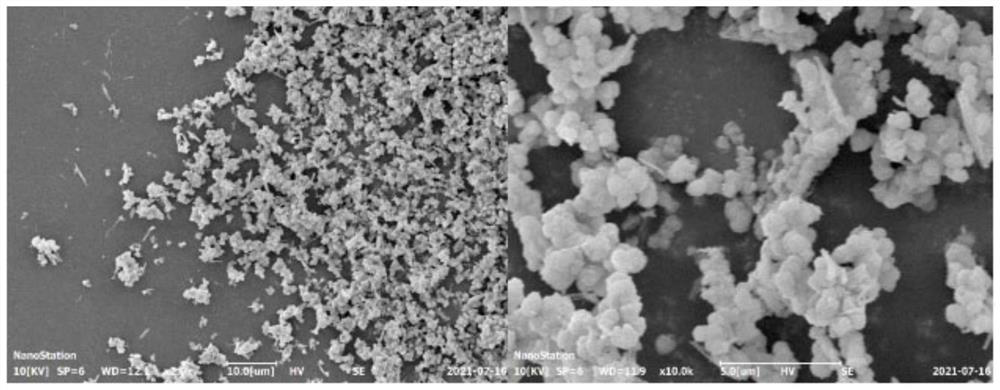

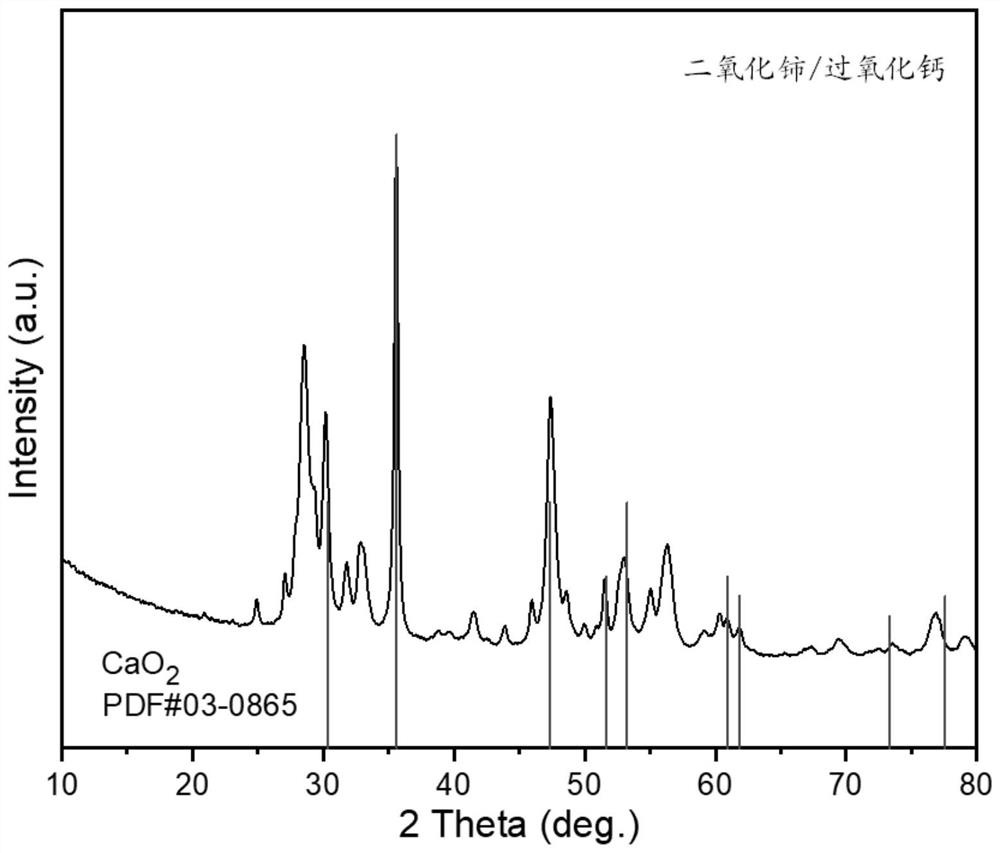

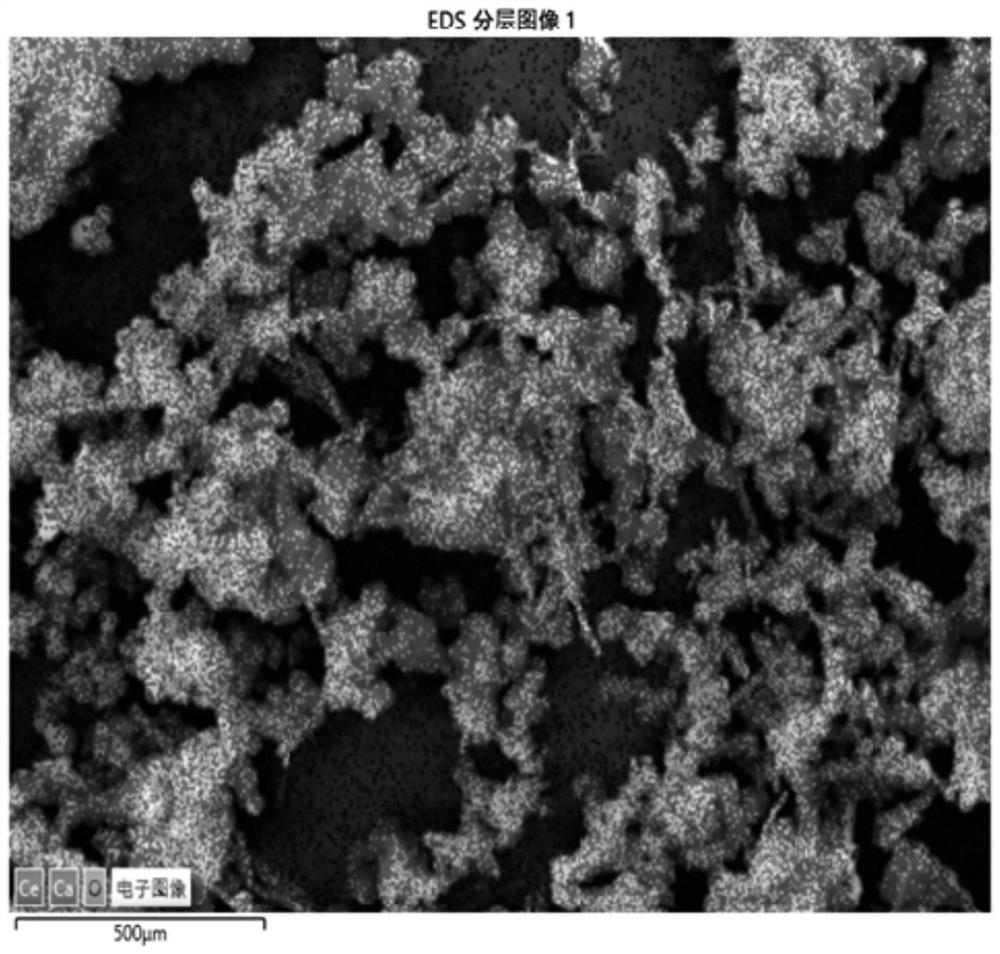

[0040] This embodiment prepares the calcium peroxide composite material supported by cerium oxide, and the preparation method is:

[0041] (1) Get 5.0g cerium chloride and dissolve it in 200mL ultrapure water, then use oxalic acid to adjust the pH=2 of the solution, then take out 30mL saturated ammonia water and dissolve it in 20mL ultrapure water to make a dilute ammonia solution, and turn it at 400 rpm Slowly add ammonia solution dropwise to the cerium chloride solution under the rotating speed of 100°C. After reacting for 1 hour, put the solution containing the white precipitate in a water bath at 90°C to mature for 3 hours, then filter and separate, wash with water twice, and then remove it at 110°C Drying at 900°C and then calcining at 900°C to obtain ceria.

[0042] (2) Take 0.5g of cerium oxide, disperse it in 40mL of ultrapure water, then weigh 3.5g of CaCl 2 , was added to the above solution, and then 25 mL of 30% H 2 o 2 , Add 10 mL of saturated ammonia water drop...

Embodiment 2

[0044] This embodiment prepares the calcium peroxide composite material supported by cerium oxide, and the preparation method is:

[0045] (1) Get 6.0g of cerium chloride and dissolve it in 250mL ultrapure water, then use oxalic acid to adjust the pH=2.5 of the solution, then take out 35mL saturated ammonia water and dissolve it in 20mL ultrapure water to make a dilute ammonia solution, at 400 rpm Slowly add the aqueous ammonia solution to the cerium chloride solution at a high speed, react for 1 hour, place the solution containing the white precipitate in a water bath at 95°C for aging for 2 hours, then filter and separate, wash with water three times, Drying at 950°C and then calcining to obtain cerium dioxide.

[0046] (2) Take 0.6g of cerium oxide, disperse it in 45mL of ultrapure water, then weigh 4g of CaCl 2 , was added to the above solution, and then 30 mL of 30% H 2 o 2 , Add 15 mL of saturated ammonia water dropwise while stirring, and then cool in ice water for h...

Embodiment 3

[0048] This embodiment prepares the calcium peroxide composite material supported by cerium oxide, and the preparation method is:

[0049] (1) Get 3.0g cerium chloride and dissolve it in 150mL ultrapure water, then use oxalic acid to adjust the pH=1.5 of the solution, then take out 25mL saturated ammonia water and dissolve it in 10mL ultrapure water to make dilute ammonia solution, at 400 rpm Slowly add ammonia solution dropwise to the cerium chloride solution under the rotating speed of 100°C. After reacting for 1 hour, put the solution containing the white precipitate in a water bath at 85°C for aging for 4 hours, then filter and separate, wash with water twice, and place it at 105°C Dry at 910°C and then calcined to obtain cerium dioxide.

[0050] (2) Take 0.3g of cerium oxide, disperse it in 35mL of ultrapure water, then weigh 2g of CaCl 2 , was added to the above solution, and then 20 mL of 30% H 2 o 2 , Add 8 mL of saturated ammonia water dropwise while stirring, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com