Layer-by-layer self-assembled composite antibacterial film and preparation method thereof

A layer-by-layer self-assembly, composite antibacterial technology, applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of strong network chain gaps and unsatisfactory mechanical properties, and achieve improved Mechanical properties, good bacteriostatic effect, excellent bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

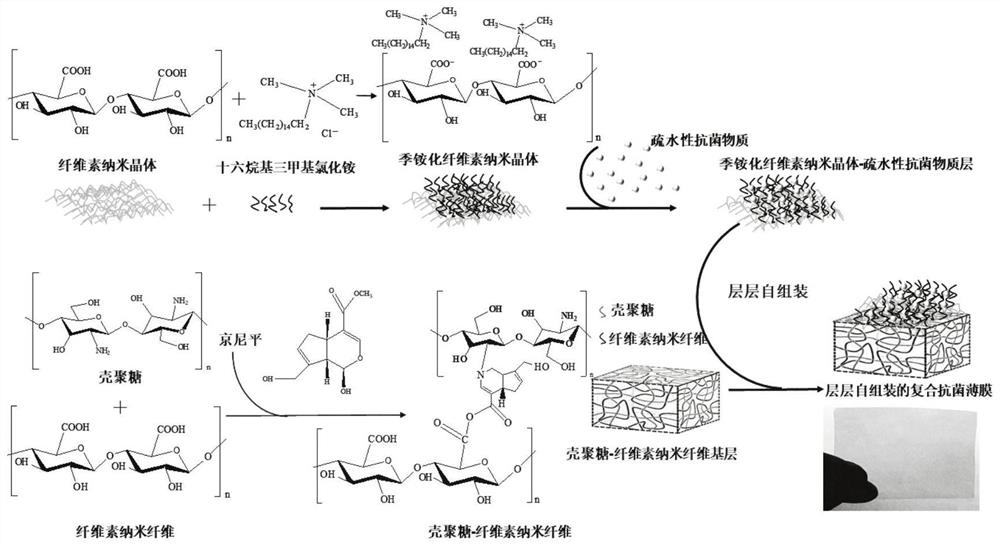

[0026] Embodiment 1 A kind of preparation of layer by layer self-assembled composite antibacterial film 1

[0027] 1. the preparation method of chitosan-cellulose nanofiber base layer in the composite antibacterial film of self-assembly layer by layer, comprising steps:

[0028] S1, preparation of chitosan solution: weigh 3g of chitosan in a beaker, add 200mL of glacial acetic acid solution with a mass fraction of 1%, place it on a magnetic stirrer and stir for 6 hours at room temperature to obtain a chitosan solution;

[0029] S2, preparation of chitosan-cellulose nanofiber crosslinking solution: add 0.09g cellulose nanofiber and 0.007g genipin to the chitosan solution and stir for 30min, wherein genipin is the crosslinking agent to obtain the shell Polysaccharide-cellulose nanofiber crosslinking solution;

[0030] S3. Preparation of the chitosan-cellulose nanofiber base layer: place the chitosan-cellulose nanofiber crosslinking solution in an ultrasonic cleaner for 1 hour t...

Embodiment 2

[0035] Embodiment 2 A kind of preparation of layer by layer self-assembled composite antibacterial film 2

[0036] 1. the preparation method of chitosan-cellulose nanofiber base layer in the composite antibacterial film of self-assembly layer by layer, comprising steps:

[0037] S1, preparation of chitosan solution: weigh 10 g of chitosan in a beaker, add 500 mL of glacial acetic acid solution with a mass fraction of 1.5%, place on a magnetic stirrer and stir at room temperature for 15 hours to obtain a chitosan solution;

[0038] S2, preparation of chitosan-cellulose nanofiber crosslinking solution: add 0.02g cellulose nanofiber and 0.01g genipin to the chitosan solution and stir for 10min, wherein genipin is the crosslinking agent to obtain the shell Polysaccharide-cellulose nanofiber crosslinking solution;

[0039] S3. Preparation of chitosan-cellulose nanofiber base layer: put the chitosan-cellulose nanofiber cross-linking solution in an ultrasonic cleaner for 0.5h to rem...

Embodiment 3

[0044] Embodiment 3 A kind of preparation of layer by layer self-assembled composite antibacterial film 3

[0045] 1. the preparation method of chitosan-cellulose nanofiber base layer in the composite antibacterial film of self-assembly layer by layer, comprising steps:

[0046] S1, preparation of chitosan solution: weigh 20g of chitosan in a beaker, add 1000mL of glacial acetic acid solution with a mass fraction of 2%, place on a magnetic stirrer and stir for 8 hours at room temperature to obtain a chitosan solution;

[0047] S2, preparation of chitosan-cellulose nanofiber crosslinking solution: add 0.45g cellulose nanofiber and 0.015g genipin to the chitosan solution and stir for 60min, wherein genipin is the crosslinking agent to obtain the shell Polysaccharide-cellulose nanofiber crosslinking solution;

[0048] S3. Preparation of the chitosan-cellulose nanofiber base layer: place the chitosan-cellulose nanofiber crosslinking solution in an ultrasonic cleaner for 3 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com