Preparation method of high-strength low-resistance mildew-proof filtering material

A filter material and low-resistance technology, applied in the direction of filtration separation, separation method, dispersed particle filtration, etc., can solve the problems of uneven distribution of active ingredients, short service life of products, and less active factors in filtration, so as to improve energy transfer and increase The effect of lubricity and loose structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

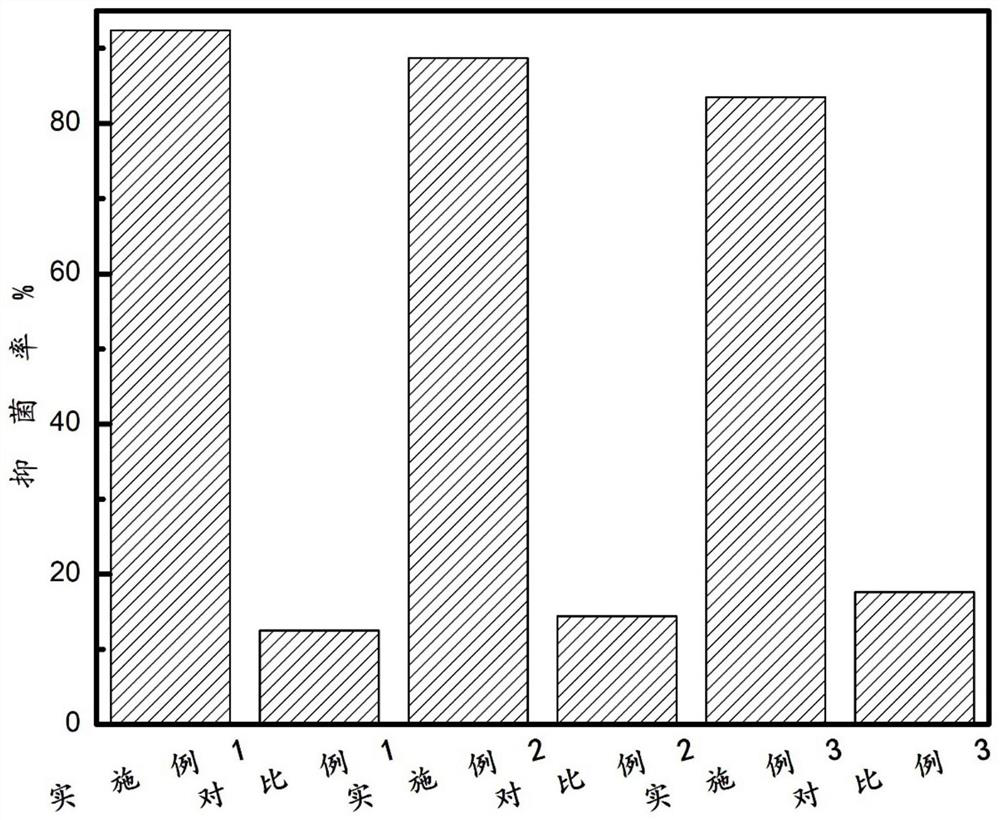

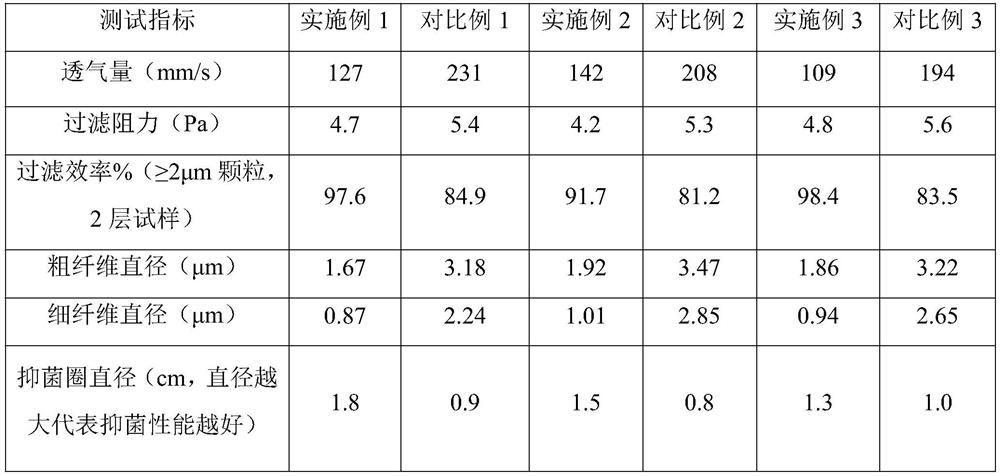

Examples

Embodiment 1

[0056] The preparation method of the high-strength and low-resistance mildew-proof filter material described in the present embodiment 1 consists of the following steps:

[0057] (1) Dry polypropylene chips with different intrinsic viscosities (0.3 dL / g for low intrinsic viscosity and 0.9 dL / g for high intrinsic viscosity) at 105°C for 3 hours.

[0058] (2) The dried high intrinsic viscosity polypropylene slices, fluid additive Enox DTBP, and mesoporous inorganic electret silica (average particle size is 150nm) are mixed in a twin-screw in a mass ratio of 100:3.5:8 After blending in the extruder, extrude, condense, air-dry, and pelletize the pelletizer to obtain the polymer slice blended modified product, wherein the extrusion temperature is 200°C, the condensation temperature is 30°C, the air-drying time is 30min, and pelletized The size of machine-cut pellets is 40 μm, and the blended modified product with high intrinsic viscosity is finally obtained.

[0059] (3) The dried...

Embodiment 2

[0074] The preparation method of the high-strength and low-resistance mildew-proof filter material described in this embodiment 2 consists of the following steps:

[0075] (1) Polybutylene terephthalate chips with different intrinsic viscosities (low intrinsic viscosity 0.6 dL / g, high intrinsic viscosity 1 dL / g) were dried at 85°C for 5 hours.

[0076] (2) The dried high intrinsic viscosity polybutylene terephthalate slices, fluid additive FM, and mesoporous inorganic electret agent titanium dioxide (average particle size is 300nm) are mixed in a mass ratio of 100:0.8:6 Proportion After blending in a twin-screw extruder, extrude, condense, air-dry, and pelletize with a pelletizer to obtain a polymer chip blending modification, wherein the extrusion temperature is 230°C, the condensation temperature is 40°C, and the air-drying time is After 40 minutes, the particle size of the granulator was 50 μm, and finally a high intrinsic viscosity blended modified product was obtained.

...

Embodiment 3

[0092] The preparation method of the high-strength and low-resistance mildew-proof filter material described in this embodiment 3 consists of the following steps:

[0093] (1) Dry polyethylene terephthalate chips with different intrinsic viscosities (low intrinsic viscosity is 0.5dL / g, high intrinsic viscosity is 1.2dL / g) at 115°C for 2.5h .

[0094] (2) The dried high-intrinsic-viscosity polyethylene terephthalate chips, fluid additive WS, and mesoporous inorganic electret agent zinc sulfide (average particle size 300nm) were mixed in a mass ratio of 100:4:6 Ratio After blending in a twin-screw extruder, extrude, condense, air-dry, and pelletize with a pelletizer to obtain a polymer slice blended modified product, wherein the extrusion temperature is 220°C, the condensation temperature is 40°C, and the air-drying time is After 35 minutes, the particle size of the granulator was 50 μm, and finally a high intrinsic viscosity blended modified product was obtained.

[0095] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com