Method for preparing low-density digestion-resistant starch

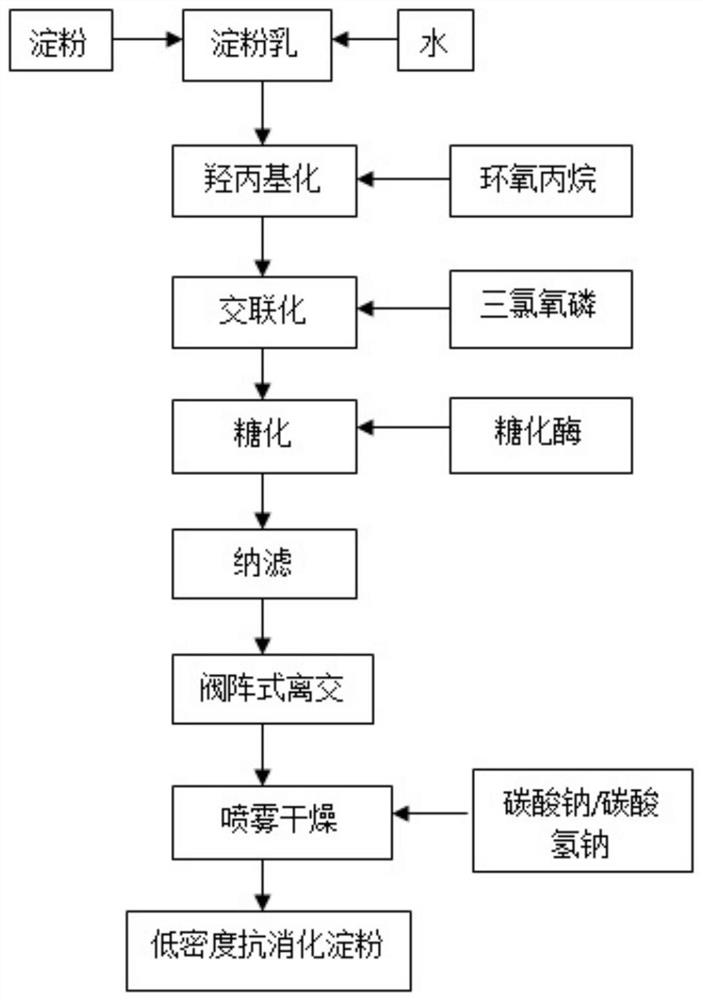

A technology of anti-digestion starch and low density, applied in the field of starch processing, can solve the problems of high density and low purity of anti-digestion starch, and achieve the effect of simple operation, large-scale industrial production and application value, and improvement of content and purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) 15g of waxy cornstarch is mixed with 100ml of water to prepare 15% (g / ml) starch milk, and NaOH is added dropwise to adjust the pH value of the starch milk to 11;

[0030] (2) Add 0.75g of propylene oxide and react at 40°C for 22h;

[0031] (3) the phosphorus oxychloride that adds 0.009g again after reaction finishes and continues reaction;

[0032] (4) After the reaction, the pH value of the solution was adjusted to 4.5, and 100 U / g of glucoamylase was added to react for 30 minutes at 60° C., and the enzyme was killed in a boiling water bath to obtain a content of resistant starch of 58%;

[0033] (5) The above-mentioned feed liquid is passed through a 200 Da nanofiltration membrane, until the glucose content in the active ingredient of the concentrated solution is 3.5%, and the content of resistant starch is 94%;

[0034] (6) Get the above-mentioned concentrated solution and carry out valve-array continuous ion exchange to remove cations and anions, and the condu...

Embodiment 2

[0037] (1) 200 g of waxy cornstarch is mixed with 800 ml of water to prepare 25% (g / ml) starch milk, and NaOH is added dropwise to adjust the pH value of the starch milk to 11.8;

[0038] (2) Add 18g of propylene oxide and react at 43°C for 24h;

[0039] (3) The phosphorus oxychloride that adds 0.016g again after reaction finishes and continues reaction;

[0040] (4) After the reaction, the pH value of the solution was adjusted to 4.5, and 100 U / g of glucoamylase was added to react at 60° C. for 30 minutes, and the enzyme was killed in a boiling water bath to obtain a content of 63% resistant starch;

[0041] (8) passing the above feed liquid through a nanofiltration membrane with a molecular weight of 200 Da until the glucose content in the concentrated solution is less than 1.5%, and the purity is 97%;

[0042] (5) Take the above-mentioned concentrated solution and carry out valve-array continuous ion exchange to remove cations and anions, and the conductivity of the feed l...

Embodiment 3

[0045] (1) Mix 600 g of waxy cornstarch with 2000 ml of water to prepare 30% (g / ml) starch milk, and add dropwise NaOH to adjust the pH of the starch milk to 12;

[0046] (2) Add 60g of propylene oxide and react at 40°C for 22h;

[0047] (3) The phosphorus oxychloride that adds 0.6g again after reaction finishes and continues reaction;

[0048] (4) After the reaction, the pH value of the solution was adjusted to 4.5, and 100 U / g of glucoamylase was added to react for 30 minutes at 60° C., and the enzyme was quenched in a boiling water bath to obtain a digestible starch content of 62%;

[0049] (5) Pass the above-mentioned feed liquid through a 200 Da nanofiltration membrane until the glucose content in the concentrated solution is 4%, and the purity is 93%;

[0050] (6) Get above-mentioned concentrated solution and carry out valve array type continuous ion exchange, remove cation and anion, the conductivity of feed liquid is 11 μ s / cm;

[0051] (7) Add 92g sodium bicarbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com