High-performance silicon-carbon composite material, preparation method thereof and lithium ion battery

A technology of silicon-carbon composite materials and composite materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problem of limiting electron conduction rate, difficulty in ensuring fast transmission, and rapid capacity decay, etc. problems, to achieve the effect of wide source of raw materials, excellent electrochemical performance and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0100] The invention provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0101] 1) After ball milling silicon powder and graphene source, silicon / graphene composite material is obtained;

[0102] 2) After mixing the silicon / graphene composite material and MAX slurry obtained in the above steps, a mixture is obtained;

[0103] 3) The mixture obtained in the above steps and the etchant are mixed again, and reacted to obtain a silicon-carbon composite material.

[0104] The present invention can correspond to the parameters and selection of raw materials and products in the above-mentioned preparation method, as well as the corresponding optimization principles, and the parameters and selection of raw materials and products in the aforementioned composite materials, as well as the corresponding optimization principles, and will not repeat them here. A repeat.

[0105] In the present invention, silicon powder and graphene source...

Embodiment 1

[0147] With expanded graphite, D50=60nm silicon powder, Ti 2 AlC as raw material

[0148] First, mix silicon powder and expanded graphite with a particle size of D50=60nm according to a mass ratio of 1:1, and ball mill for 2 hours to obtain a graphene-coated silicon composite material;

[0149] Then weigh the composite material mass ratio of 5% Ti 2 Ultrasonic dispersion of AlC in absolute ethanol, adding graphene-coated silicon composites to Ti 2 In AlC solution, ultrasonically disperse evenly;

[0150] Then the above material is subjected to hydrothermal treatment under the condition of 65% sodium hydroxide solution in mass fraction and 270°C to remove Ti 2 Al in AlC, then fully centrifuged and washed with ethanol and deionized water, and spray-dried to obtain the silicon-carbon composite material Si@GE@Ti 2 c.

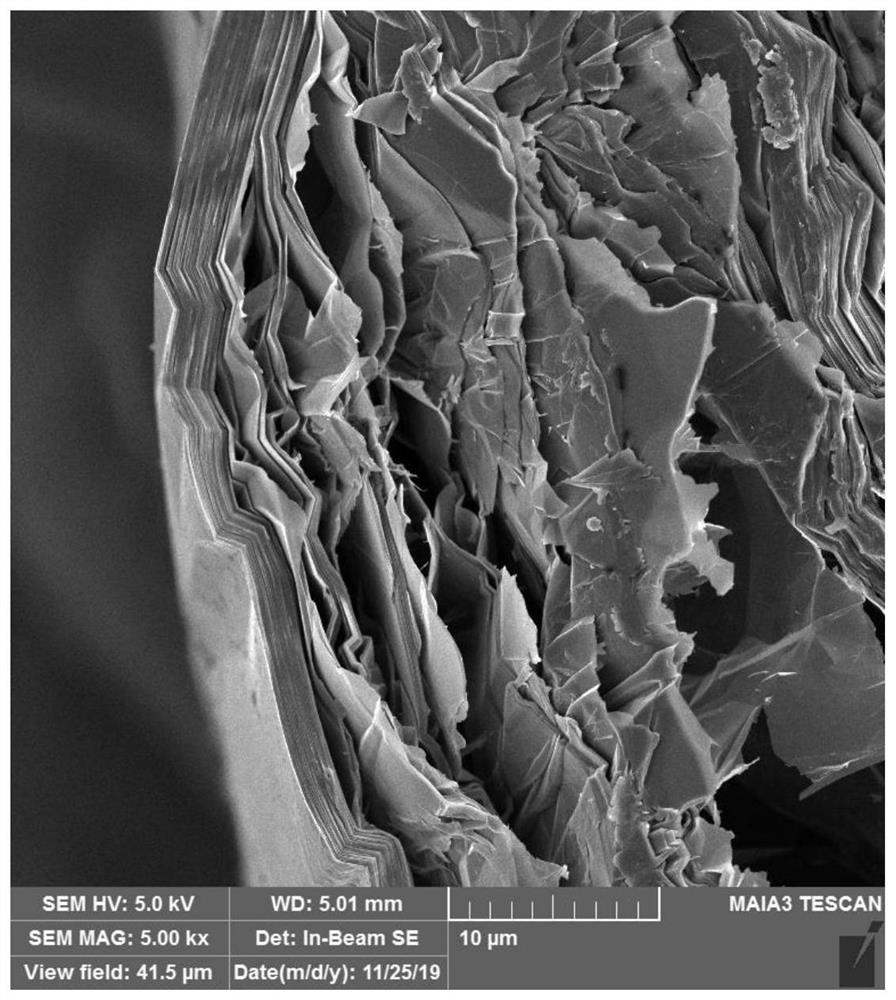

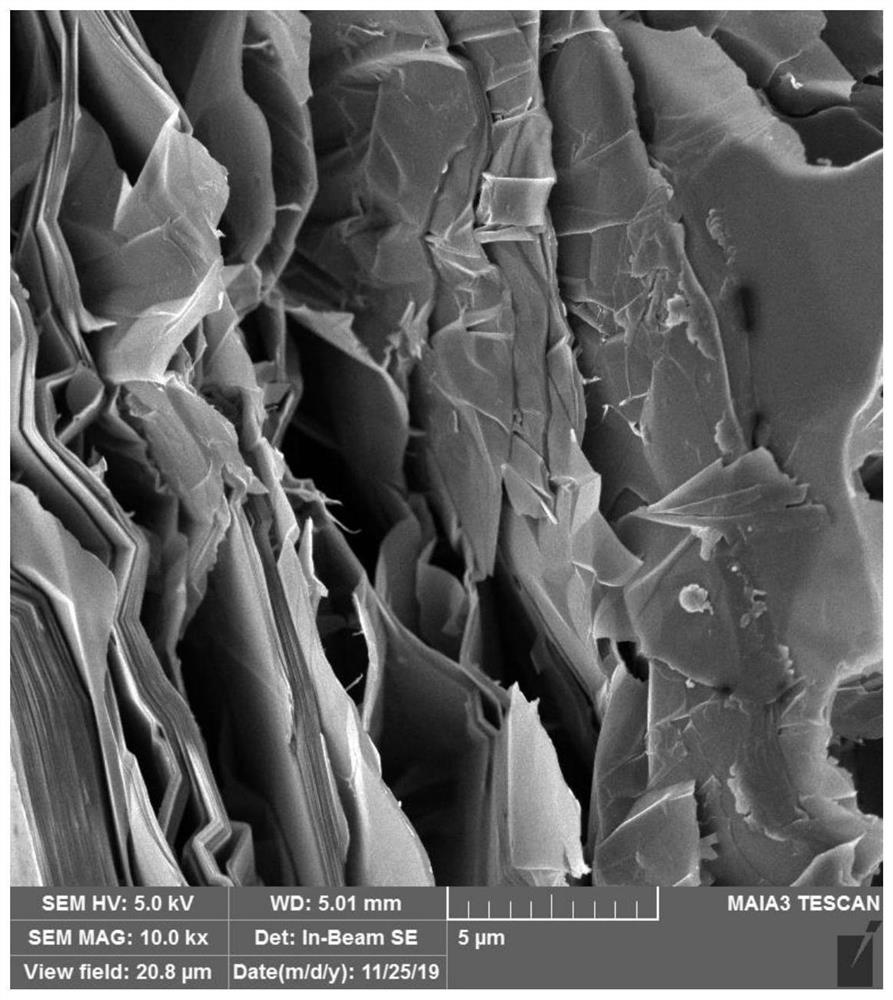

[0151] The silicon-carbon composite material prepared in Example 1 of the present invention was characterized.

[0152] see figure 1 , figure 1 TEM transmis...

Embodiment 2

[0161] With expanded graphite, D50=80nm silicon powder, Ti 3 SiC 2 as raw material

[0162] First, mix silicon powder and expanded graphite with a particle size of D50=80nm according to a mass ratio of 1:1.5, and ball mill for 2 hours to obtain a graphene-coated silicon composite material;

[0163] Then weigh the composite material mass ratio of 8% Ti 3 SiC 2 Ultrasonic dispersion in absolute ethanol to add graphene-coated silicon composites to Ti 3 SiC 2 In the solution, ultrasonically disperse evenly;

[0164] Then the above material is subjected to hydrothermal treatment under the condition of 40% hydrofluoric acid solution in mass fraction and 60°C to remove Ti 3 SiC 2 Si in the Si, then fully centrifuged with ethanol and deionized water, and spray-dried to obtain the silicon-carbon composite material Si@GE@Ti 2 c.

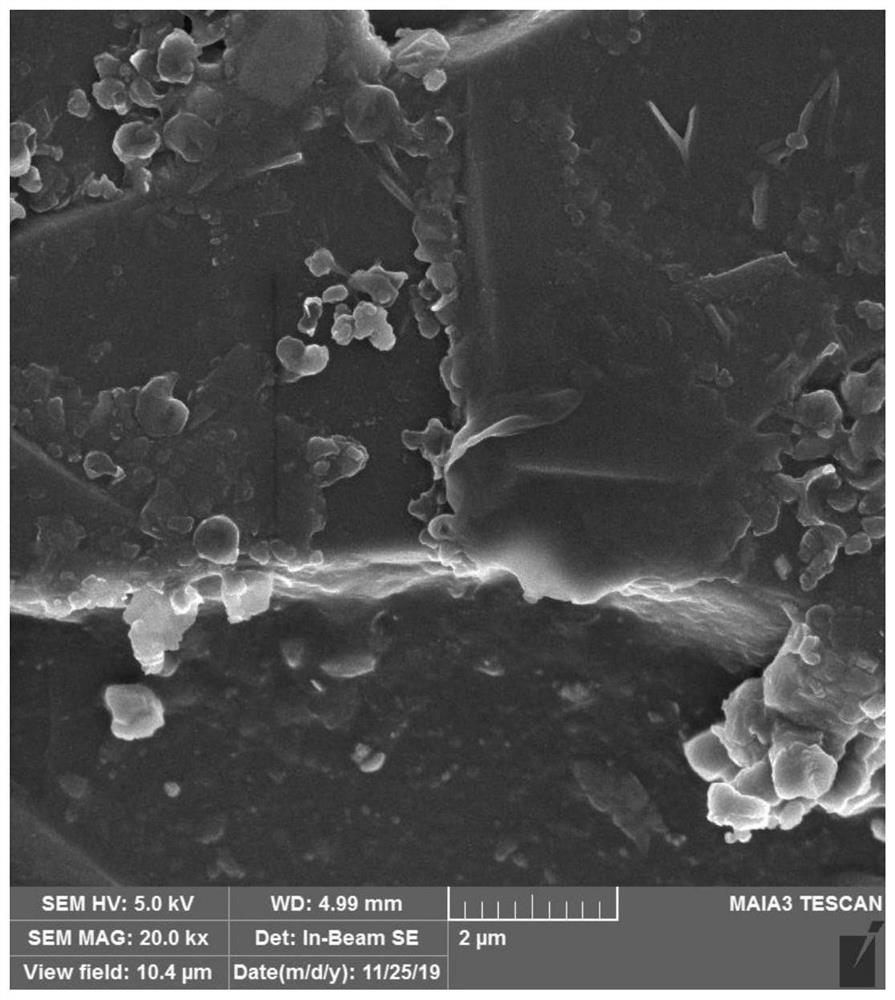

[0165] The silicon-carbon composite material prepared in Example 2 of the present invention was characterized.

[0166] see image 3 , image 3 TE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com