A kind of quick-drying bio-based water-based polyurethane coating based on stimulus response mode and preparation method thereof

A water-based polyurethane, stimuli-responsive technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex preparation process, and achieve the effect of excellent low temperature and fast drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

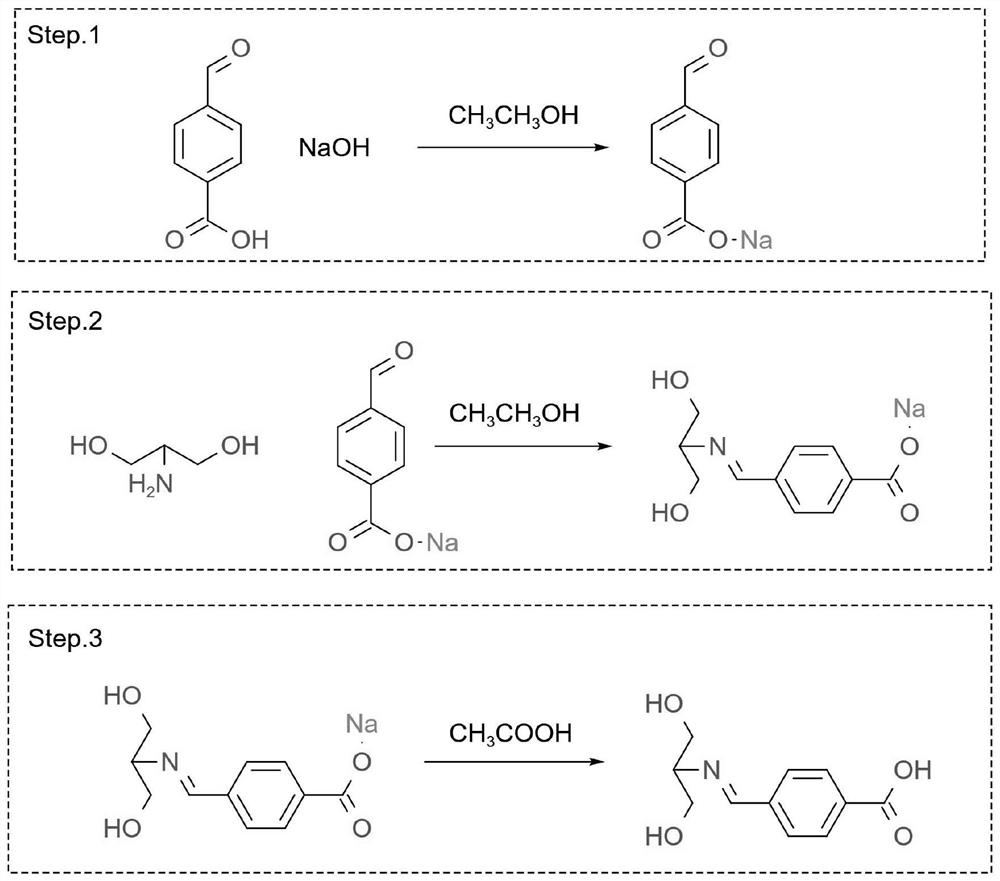

[0033] In the present embodiment, the quick-drying type internal emulsifier containing Schiff base is synthesized, such as image 3 shown, including the following steps:

[0034] (1) 4-aldehyde benzoic acid (1.5 g, 10 mmol) and sodium hydroxide (0.4 g, 10 mmol) were sequentially added to a mixed solution of ethanol / water (50 mL / 30 mL), and the reaction was stirred for ten minutes. In a weak alkaline solution, the carboxyl group in 4-aldehyde benzoic acid reacts with -OH of sodium hydroxide to obtain sodium 4-aldehyde benzoate, and reaction solution A is prepared.

[0035] (2) The reaction solution A was added dropwise to 2-amino-1,3 propanediol (10 mmol), acetic acid was added as a catalyst, and the reaction was stirred at room temperature for 30 minutes. The aldehyde group in the sodium 4-aldehyde benzoate reacts with the amine group of the 2-amino-1,3 propanediol to synthesize a Schiff base, and then the reaction solution B is obtained.

[0036] (3) dropwise add acetic aci...

Embodiment 2

[0046] The synthetic route of the fast-drying internal emulsifier containing dynamic disulfide bonds in this example, such as Figure 4 shown, including the following steps:

[0047] (1) 2,2'-dipyridine disulfide (11.206g, 50mmol) was dissolved in 80mL of absolute ethanol, 3-mercapto-1,2-propanediol (3.782g, 35mol) was added, and acetic acid was added dropwise as a The catalyst was stirred at room temperature for 3h. The pyridine disulfide in 2,2'-dipyridine disulfide undergoes a disulfide exchange with the mercapto-SH group in 3-mercapto-1,2-propanediol in a weakly acidic environment to give 3-(pyridine-2 - dimercapto)-1,2-propanediol. After the solvent was removed under reduced pressure, reaction solution A was obtained.

[0048] (2) The reaction solution A (4.346 g, 20 mmol) was dissolved in 60 mL of absolute ethanol, 3-mercaptopropionic acid (2.122 g, 20 mmol) was added, and acetic acid was added dropwise as a catalyst, and the mixture was stirred at room temperature fo...

Embodiment 3

[0068] The water-based polyurethane coatings of Example 1-2 and Comparative Example 1 were sprayed on the substrate, and the surface dryness and the dryness time were recorded with reference to GB / T 19250-2003, Image 6 It is the actual picture of the coatings of Example 1-2 and Comparative Example 1 sprayed on the substrate; according to the standard ISO1184-1983 "Determination of Tensile Properties of Plastic Films", the mechanics of water-based polyurethane coatings are tested by tensile testing machine; according to GB / T 6739-2006 "Determination of Hardness of Paint Films by Pencil Method of Paints and Varnishes" specifically requires that the hardness of coatings should be tested with a pencil scratch hardness tester. The results are shown in Table 1. It can be seen from Table 1 that both the surface dry time and the hard dry time in Examples 1 and 2 are significantly shortened. In terms of performance, the tensile strength and hardness of Examples 1 and 2 are also signi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com