Method for green synthesis of nano copper oxide by using galangal extracting solution

A nano-copper oxide, green synthesis technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of toxicity of reducing agents and stabilizers, high requirements for instruments and equipment, environmental pollution, etc. The effect of secondary pollution and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

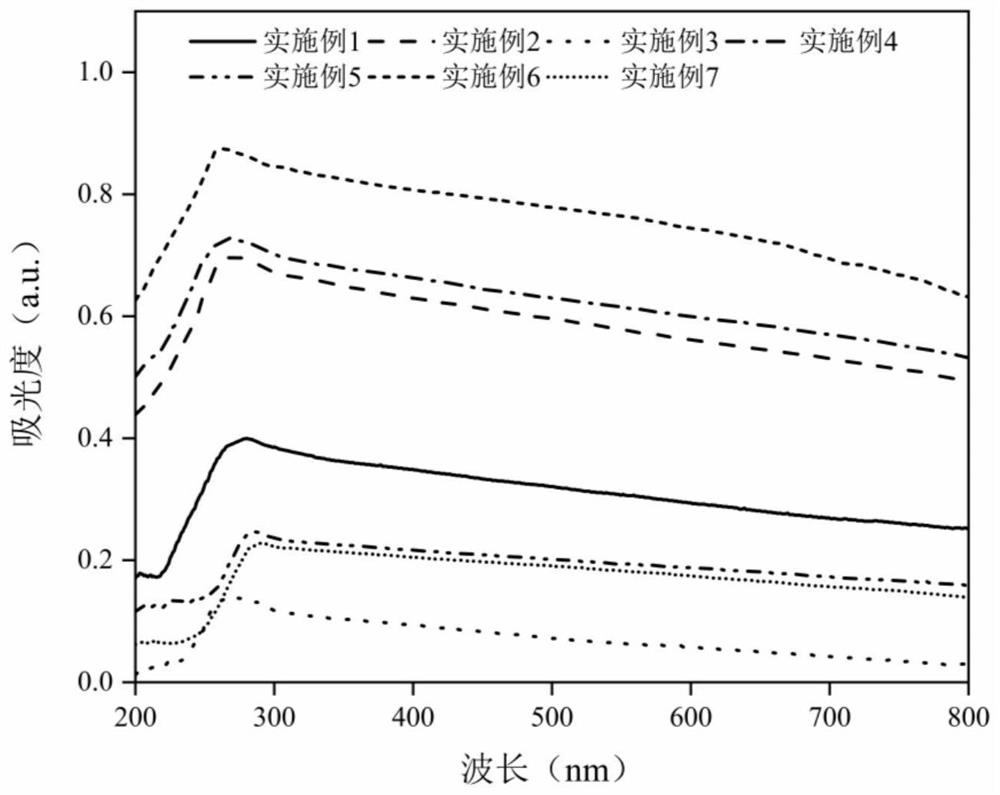

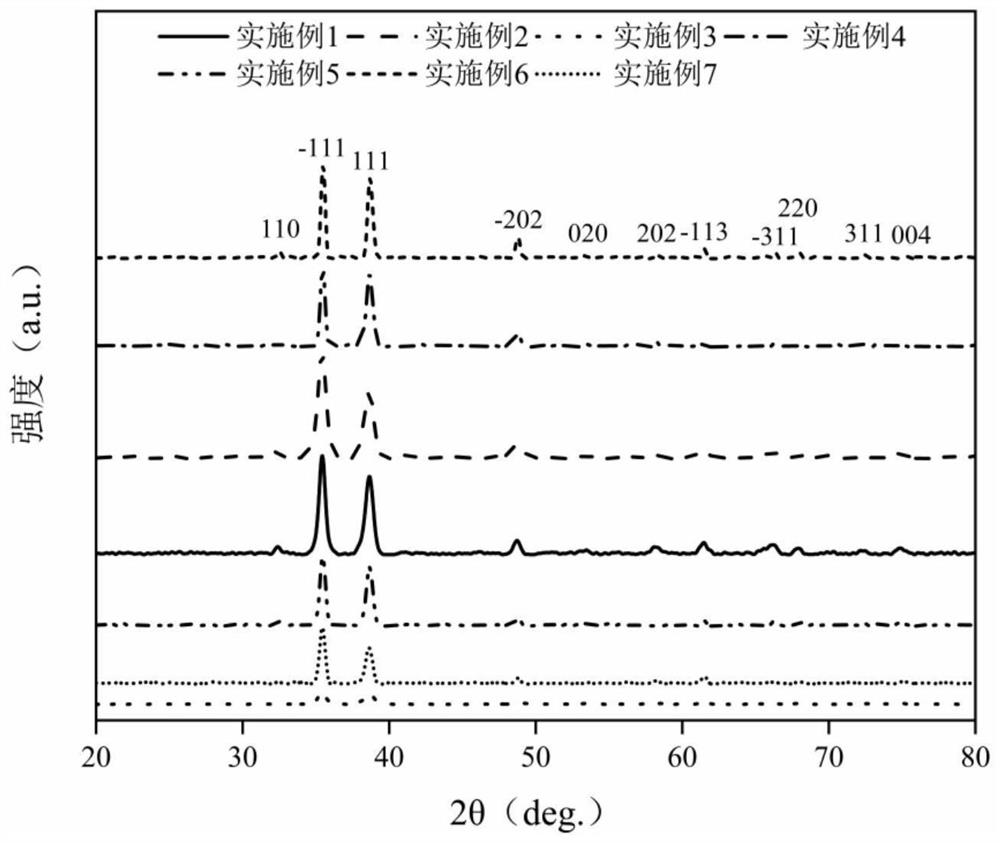

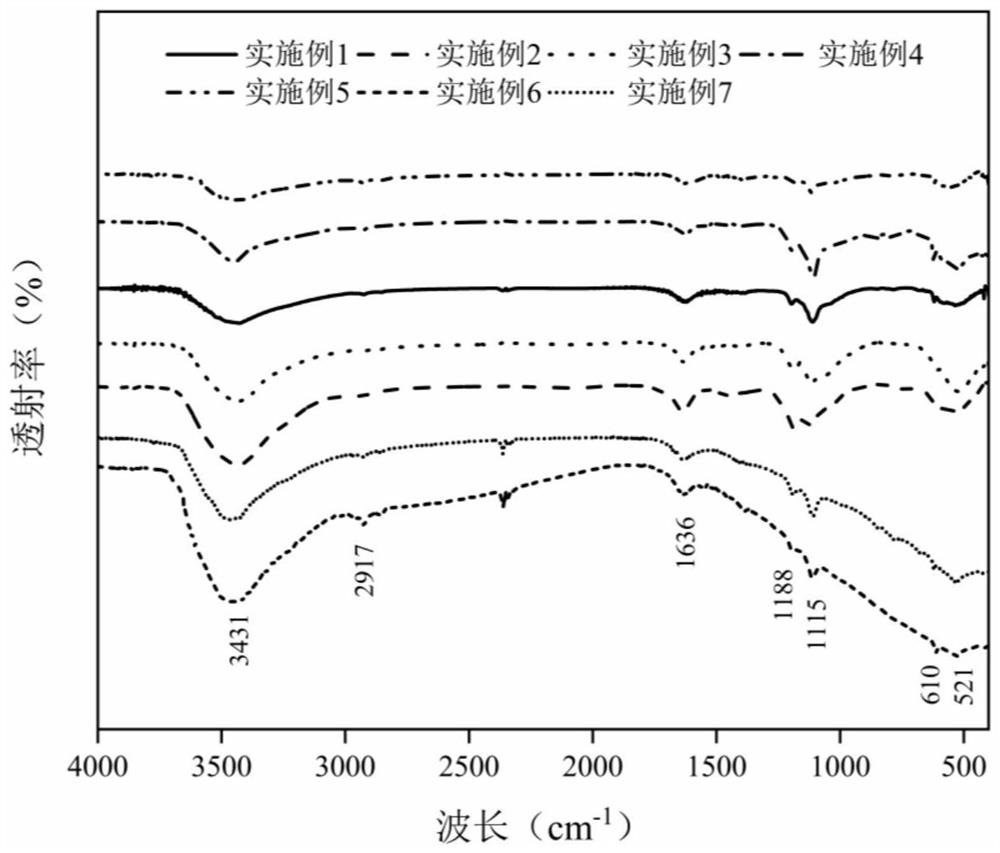

Embodiment 1

[0051] (1) Weigh 10g of dried galangal powder and place it in a beaker, add 100g of deionized water, take it out after heating and stirring at 80°C for 45min, vacuum filter through a 0.45μm microporous membrane to obtain the galangal extract, place Store at 4°C for later use.

[0052] (2) Weigh copper sulfate pentahydrate powder, add deionized water and stir to dissolve to obtain a copper sulfate solution with a concentration of 0.01 g / mL.

[0053] (3) the galangal extract prepared by the step (1) is mixed with the copper sulfate solution prepared by the step (2) according to a volume ratio of 1:1, and the hydrochloric acid solution is added dropwise to adjust the pH value to 4, The mixture was stirred at 60° C. for 3 h to obtain a nano-copper suspension.

[0054] (4) The nano-copper suspension prepared in the step (3) was centrifuged at 7000g for 10min, and the obtained nano-copper particles were alternately washed three times with deionized water and absolute ethanol, dried...

Embodiment 2

[0059] (1) Weigh 10g of dried galangal powder and place it in a beaker, add 100g of deionized water, take it out after heating and stirring at 80°C for 45min, vacuum filter through a 0.45μm microporous membrane to obtain the galangal extract, place Store at 4°C for later use.

[0060] (2) Weigh copper sulfate pentahydrate powder, add deionized water and stir to dissolve to obtain a copper sulfate solution with a concentration of 0.01 g / mL.

[0061] (3) the galanga extract prepared by the step (1) is mixed with the copper sulfate solution prepared by the step (2) according to a volume ratio of 1:2, and the hydrochloric acid solution is added dropwise to adjust the pH value to 4, The mixture was stirred at 60° C. for 3 h to obtain a nano-copper suspension.

[0062] (4) The nano-copper suspension prepared in the step (3) was centrifuged at 7000g for 10min, and the obtained nano-copper particles were alternately washed three times with deionized water and absolute ethanol, dried ...

Embodiment 3

[0067] (1) Weigh 10g of dried galangal powder and place it in a beaker, add 100g of deionized water, take it out after heating and stirring at 80°C for 45min, vacuum filter through a 0.45μm microporous membrane to obtain the galangal extract, place Store at 4°C for later use.

[0068] (2) Weigh copper sulfate pentahydrate powder, add deionized water and stir to dissolve to obtain a copper sulfate solution with a concentration of 0.01 g / mL.

[0069] (3) the galanga extract prepared by the step (1) is mixed with the copper sulfate solution prepared by the step (2) according to a volume ratio of 1:3, and the hydrochloric acid solution is added dropwise to adjust the pH value to 4, The mixture was stirred at 60° C. for 3 h to obtain a nano-copper suspension.

[0070] (4) The nano-copper suspension prepared in the step (3) was centrifuged at 7000g for 10min, and the obtained nano-copper particles were alternately washed three times with deionized water and absolute ethanol, dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com