Fully autotrophic biological denitrification device and method

An autotrophic biological denitrification and bioreactor technology, applied in the field of biological denitrification, can solve problems such as difficult control, failure to meet denitrification requirements, and inability to remove nitrate, achieve high denitrification rate and reduce energy consumption and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

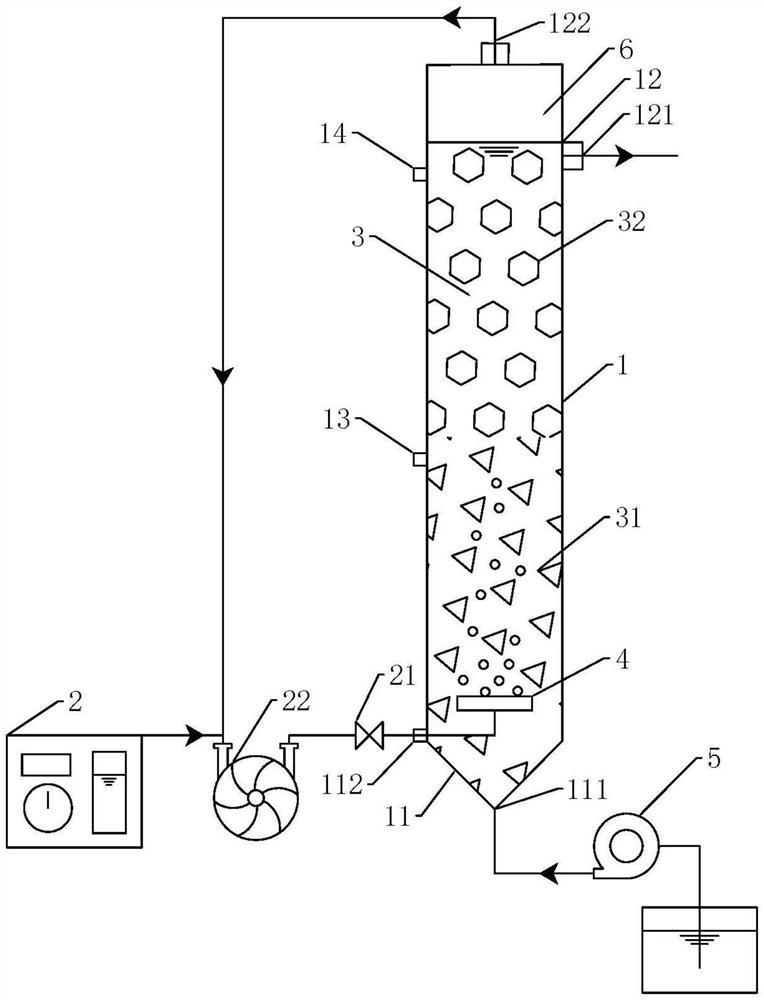

[0039] Such as figure 1 As shown, a fully autotrophic biological denitrification device includes a bioreactor 1 and a gas generator 2, the bioreactor 1 includes a water inlet 11 and a water outlet 12, and the interior of the bioreactor 1 is filled with A porous carrier 3, the porous carrier 3 includes a first reaction section 31 and a second reaction section 32 respectively adsorbed with corresponding denitrification microorganisms, the gas generator 2 is used to generate a mixed gas and introduce the mixed gas into the Inside bioreactor 1.

[0040] A gas disperser 4 is placed near the water inlet 11 in the bioreactor 1, and the gas disperser 4 is used to disperse the mixed gas. The side wall of the bioreactor 1 is respectively provided with a first sampling port 13 and a second sampling port 14 at the first reaction section 31 and the second reaction section 32, and the first sampling port 13 and the second sampling port 14 is used for real-time sampling and observation of ...

Embodiment 2

[0045] 1. Screening of hydrogen oxidizing denitrifying bacteria

[0046] The source of the strains to be screened is the sludge in the denitrification tank of a sewage treatment plant, and an appropriate amount of strains to be screened is added to the prepared autotrophic denitrification medium. The composition of the autotrophic denitrification medium is: KNO 3 1g / L, NaHCO 3 1.2g / L,KH 2 PO 40.2g / L. Use 150mL anaerobic bottle for airtight culture, the liquid volume in the anaerobic bottle is 50mL, and the bottle is filled with excess hydrogen. Sampling and measuring the change of its nitrate concentration every day, until the nitrate concentration is reduced to below 0.5mg N / L, add nitrate and hydrogen, after adding two nitrates, transfer the bacterial solution, the transfer amount is 20% ( 10 mL), the composition of the medium was the same as above. After all the nitrates were reduced to nitrogen, transfer again, repeat this three times, and then use the method of anae...

Embodiment 3

[0050] Biocarrier immobilization of hydrogen oxidizing denitrifiers and anammox bacteria:

[0051] The bioreactor of this embodiment has a diameter of 10 cm and a height of 100 cm, and is filled with ceramic porous materials with a diameter of about 5 mm, and the voids of the ceramic materials are 60%.

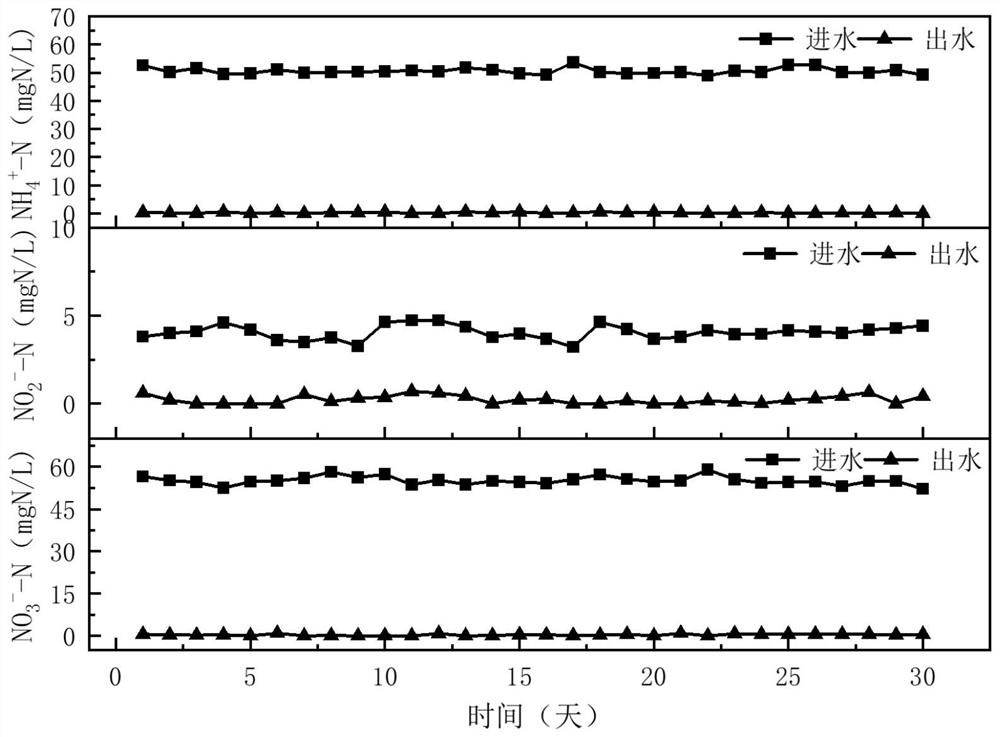

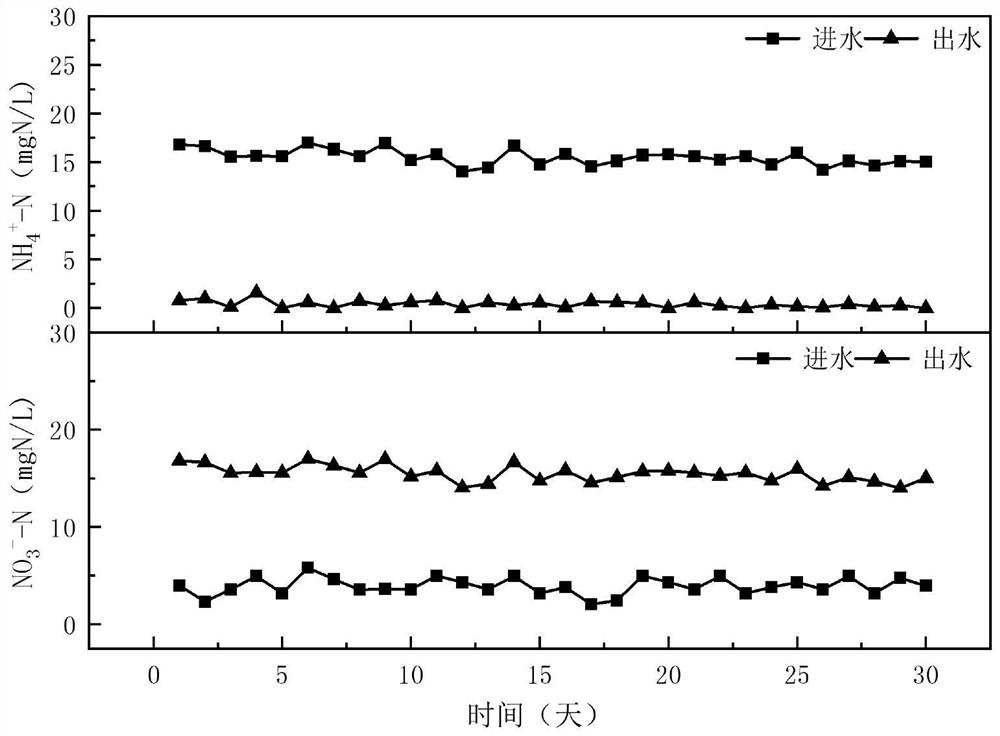

[0052] The simulated wastewater contains ammonia nitrogen, nitrite nitrogen and nitrate nitrogen, and the specific components are as follows: NH 4 Cl 0.31g / L, NaNO 2 0.35g / L, KNO 3 0.5g / L, NaHCO 3 1.2g / L,KH 2 PO 4 0.2g / L.

[0053] A gas disperser is installed at the bottom of the bioreactor, and the mixed gas of hydrogen and carbon dioxide produced by methanol cracking is fed into it. The gas produced by cracking methanol includes 70% hydrogen and about 25% carbon dioxide.

[0054] An appropriate amount of ceramic porous material is put into the pure cultured Thauera mechernichensis denitrifying bacteria and the bacteria solution of the enriched and purified anammox bac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com