Double-molten-pool heating gasification furnace

A gasifier and melting pool technology, applied in the field of new energy equipment, can solve problems such as shortage of energy, achieve the effects of improving uniformity and heating speed, solving energy shortage, and being conducive to green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

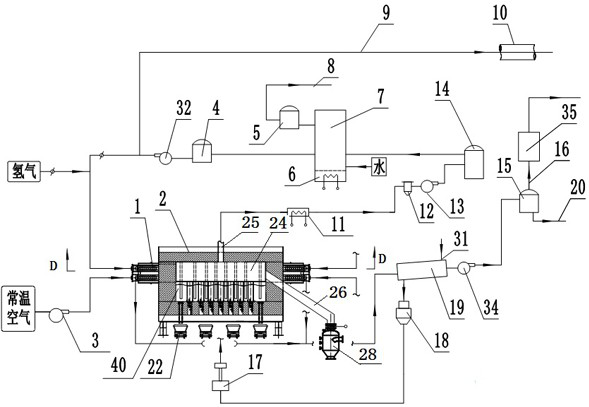

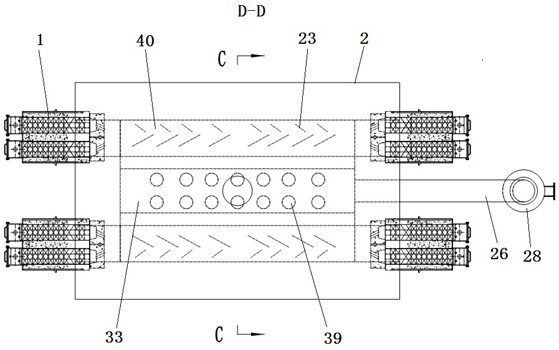

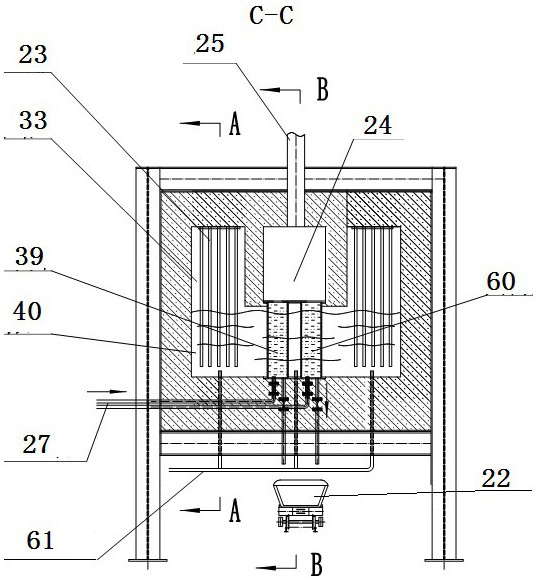

[0027] Embodiment 1 of the present invention provides a double melting pool heating gasifier, such as figure 1 As shown, it includes a gasifier 2, a straw feeding unit and a conversion separation unit. The gasification furnace 2 is a two-way combustion heating furnace, including a regenerative burner 1 and a furnace 33 on both sides. Such as Figure 2-Figure 5 As shown, the hearth is a concave structure, the hearth is provided with an outer melting pool 40 and 14 tungsten tubes 39, both sides of the hearth are provided with heat conduction bars 23, 14 tungsten tubes are located in the middle of the hearth, and the heat conduction bars and tungsten tubes are inserted into the outer melting pool . The tungsten tube is provided with an inner molten pool 60 . The inner molten pool 60 and the outer molten pool 40 can be tin molten pools, or other metal molten pools or non-metallic molten pools. The outside of the tungsten tube 39 is provided with a carbon felt protective layer,...

Embodiment 2

[0037] Another embodiment of the present invention is as Image 6 As shown, it includes a gasifier 2, a regenerative heat exchanger 37, a calcium carbide furnace 36, a straw feeding unit and a conversion separation unit. Such as Figure 7 , Figure 8 As shown, the calcium carbide furnace includes regenerative burners 1 and a furnace 33 on both sides. The furnace is provided with a tungsten tube 39, a calcium carbide tail gas collection chamber 41, a calcium carbide tail gas outlet pipe 42 and a calcium carbide raw material delivery pipe 43. The tungsten tube is a molten pool Heating equipment, the molten pool is a tin molten pool. The calcium carbide raw material delivery pipe is connected to the lower part of the tungsten pipe, the upper part of the tungsten pipe is connected to the calcium carbide tail gas collection chamber, and the calcium carbide tail gas collection chamber is connected to the calcium carbide tail gas outlet pipe. The tungsten tube can be replaced with...

Embodiment 3

[0042] The third embodiment of the present invention is as Figure 9 , Figure 10 As shown, it includes an ironmaking furnace 45, an ironmaking feeding unit and a separation unit. The separation unit includes a cooling condenser 53 , a dust collector 12 , an induced draft fan 13 , an ironmaking furnace gas tank 59 , a hydrogen tank 4 , a nitrogen delivery tank 51 and a hydrogen-nitrogen separator 57 . The hydrogen-nitrogen separator 57 is provided with a hydrogen outlet and a nitrogen outlet. The ironmaking feeding unit includes molten iron ladle 46, iron raw material conveyor 47, cooling condenser 53, CaO powder hopper 48, Fe 2 o 3 Silo 49 and mixer 50. The ironmaking furnace 45 includes regenerative burners 1 and a furnace 33 on both sides. The hearth is a concave structure, and the hearth is equipped with an outer molten pool 40, 20 tungsten pipes 39, an ironmaking furnace gas collection chamber 58, a material nozzle 54, a reducing hydrogen gas nozzle 55 and a slag dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com