Thermal interface material with high thermal conductivity and preparation process thereof

A technology of thermal interface material and preparation process, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., and can solve the problems of easy aggregation, uneven dispersion and high price of BN nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

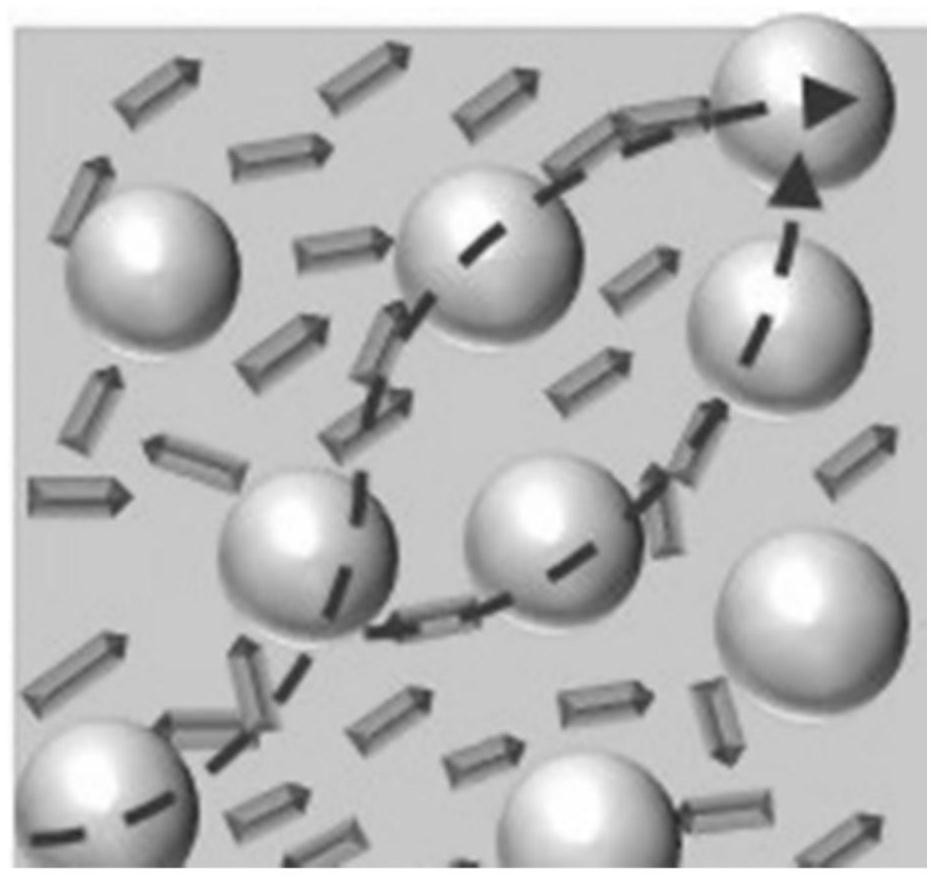

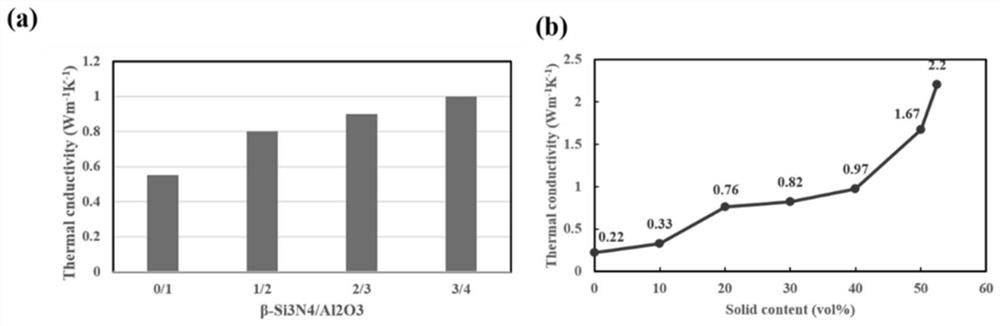

[0032] First, the self-made rod-shaped β-Si with a long diameter of 18 μm 3 N 4 and commercial 120 μm spherical Al 2 o 3 The powder is put into a vacuum oven to remove excess moisture; then, add 2.7vol% coupling agent KH560 and 0.3vol% thixotropic agent amide wax to prepare the epoxy resin matrix in the bisphenol F type epoxy resin accounting for 40.4vol% of the total volume ;The dried volume fraction is 40vol% β-Si 3 N 4 and spherical Al 2 o 3 Mixture according to m(β-Si 3 N 4 ) / m(Al 2 o 3 ) = 3 / 4 ratio, dispersed in the epoxy matrix by gravity mixing, the mixture was mixed for 10min at a rotation speed of 2000rpm and a revolution speed of 1000rpm; after that, 16.0vol% of the curing agent polyetheramine D230 and 0.6vol% The accelerator 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30) was added to the mixture; finally, the mixture was poured into a silicone mold, cured at room temperature for 8 hours, and then cured at 40°C for 2 hours. β-Si 3 N 4 / Al 2 o 3 / Epox...

Embodiment 2

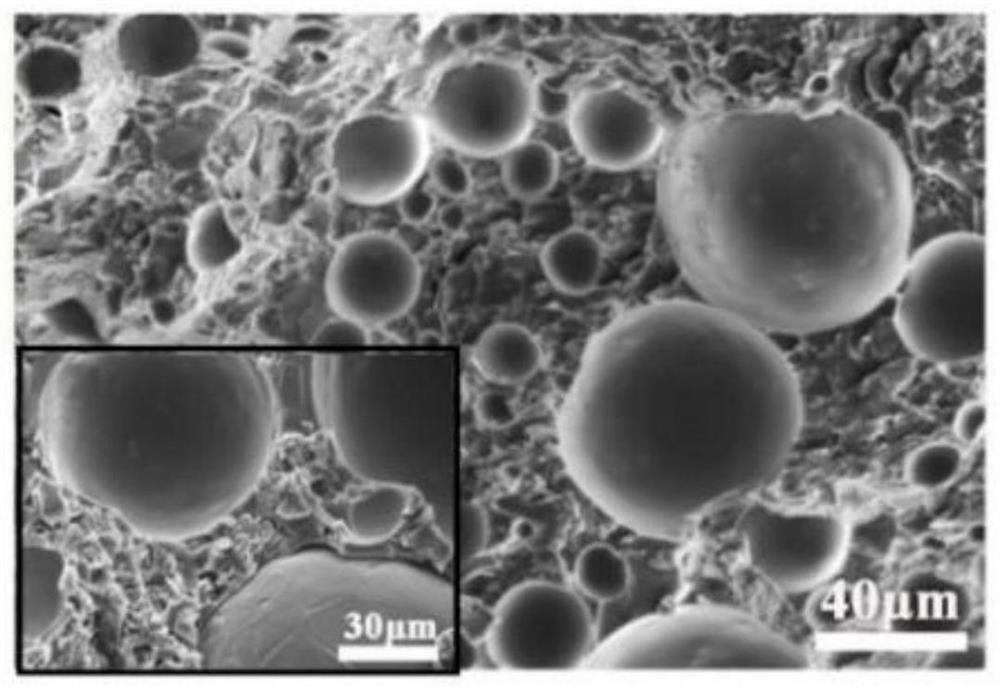

[0034] First, the self-made 10 μm rod-shaped β-Si 3 N 4 and commercial 80μm spherical Al 2 o 3 The powder is put into a vacuum oven to remove excess moisture; then, in 40.4vol% epoxy resin, add 2.7vol% coupling agent KH560 and 0.3vol% thixotropic agent amide wax to prepare epoxy resin matrix; the volume fraction that has dried is 40vol% β-Si 3 N 4 and spherical Al 2 o 3 Mixture according to m(β-Si 3 N 4 ) / m(Al 2 o 3 ) = 1 / 2 ratio, dispersed in the epoxy matrix by gravity mixing method, the mixture was mixed at a rotation speed of 1500rpm and a revolution speed of 1000rpm for 10min; after that, a total of 16.6vol% of curing agent polyamide was added to the mixture ;Finally, pour the mixture into a silicone mold, cure at room temperature for 16 hours, and then cure for 2 hours at 40°C to obtain β-Si 3 N 4 / Al 2 o 3 / Epoxy composite material with a thermal conductivity of 0.8Wm -1 K -1 . Fracture morphology, spherical Al 2 o 3 Evenly dispersed in the epoxy mat...

Embodiment 3

[0036] First, the self-made 18 μm rod-shaped β-Si 3 N 4 and commercial 100 μm spherical Al 2 o 3 The powder is put into a vacuum oven to remove excess moisture; then, in 40.4vol% epoxy resin, add 2.7vol% coupling agent and 0.3vol% thixotropic agent amide wax to prepare epoxy resin matrix; the volume fraction that has dried is 40vol % β-Si 3 N 4 and spherical Al 2 o 3 Mixture according to m(β-Si 3 N 4 ) / m(Al 2 o 3 ) = 2 / 3 ratio, dispersed in the epoxy matrix by gravity mixing, the mixture was mixed at a rotation speed of 2000rpm and a revolution speed of 1000rpm for 10min; after that, a total of 16.6vol% of curing agent polyamide was added to the mixture ;Finally, pour the mixture into a silicone mold, cure at room temperature for 10 hours, and then cure at 40°C for 3 hours to obtain β-Si 3 N 4 / Al 2 o 3 / Epoxy composite material with a thermal conductivity of 0.91Wm -1 K -1 . Fracture morphology, spherical Al 2 o 3 Evenly dispersed in the epoxy matrix, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com