Complex microbial inoculant, method for preparing microbial composite carbon source by using complex microbial inoculant, and application of microbial composite carbon source in sewage treatment

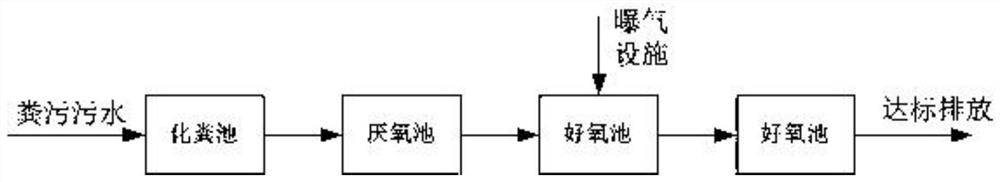

A technology of compound microbial inoculum and compound carbon source, applied in biological water/sewage treatment, microorganism-based method, biological sludge treatment, etc. The effect of increasing the internal surface area of the structure and enhancing the denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

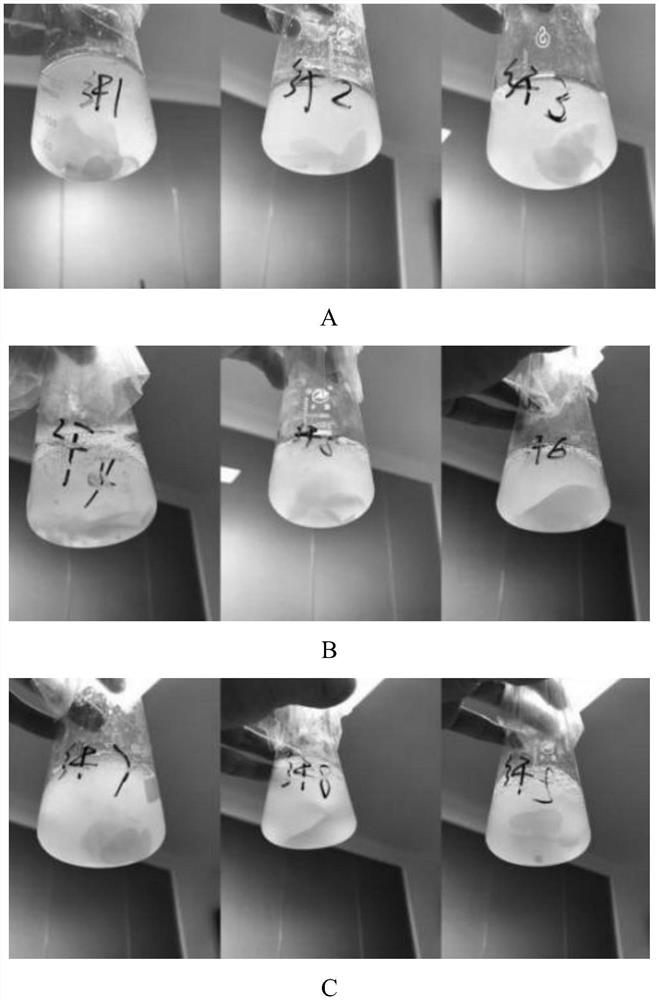

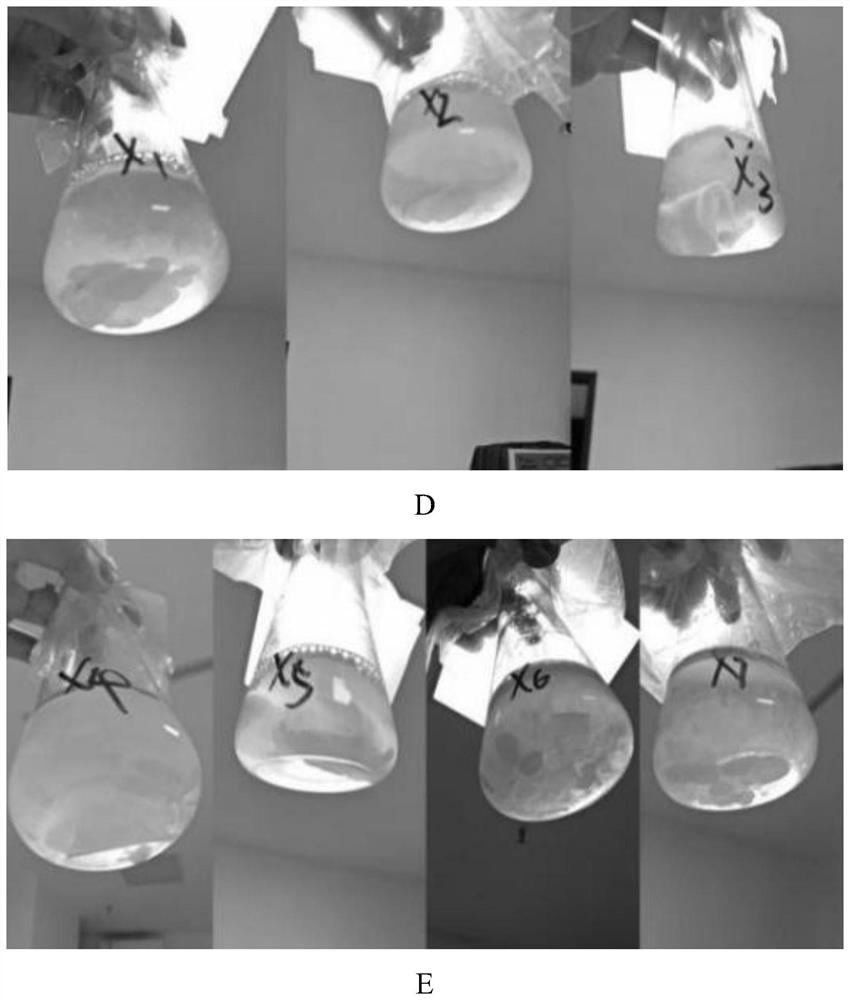

Embodiment 1

[0056] Put Aspergillus fumigatus, Aspergillus oryzae and Candida krusei into the wort of the activation medium with a concentration of 1L / L and 5 Baume degrees, and the pH is 6.0 to activate the strains; put Bacillus licheniformis, gum Put Paenibacillus and Bacillus subtilis into the activation medium LB medium (the formula of LB medium is preferably peptone 10g, sodium chloride 5g, glucose 1.5g, yeast powder 5g, add distilled water to make up 1L), pH 6.8, activate the strain; inoculate the activated bacterial solution into the corresponding culture medium for shaking culture, and then ferment in batches in the fermenter. When the total number of microorganisms > 1x10 8 When CFU / g, the storage tank collects the bacterial liquid of each strain, seals the storage tank, and stores it under the condition of ambient temperature ≤ 20°C; compound the bacterial liquid of Aspergillus fumigatus and Aspergillus oryzae at a volume ratio of 4.5:5.5 Bacterial solution, prepare composite mic...

Embodiment 2

[0060] Put Aspergillus fumigatus, Aspergillus oryzae and Candida krusei into the wort of the activation medium with a concentration of 0.5L / L and 5 Baume degrees, and the pH is 6.5 to activate the strains; Bacillus licheniformis, Put the jelly-like Paenibacillus and Bacillus subtilis into the activated medium LB medium (the formula of the LB medium is preferably peptone 10g, sodium chloride 5g, glucose 1.5g, yeast extract powder 5g, add distilled water to make up 1L), The pH is 7.2, and the bacteria are activated; the activated bacteria are inoculated into the corresponding medium for shaking culture, and then fermented in batches in the fermenter. When the total number of microorganisms > 1 × 10 8 When CFU / g, the storage tank collects the bacterial liquid of each strain, seals the storage tank, and stores it under the condition of ambient temperature ≤ 20°C; compound the bacterial liquid of Aspergillus fumigatus and Aspergillus oryzae at a volume ratio of 4:6 Bacterial soluti...

Embodiment 3

[0064] Put Aspergillus fumigatus, Aspergillus oryzae and Candida krusei into the wort of 1.5L / L activation medium with a pH of 5 degrees Baume, and the pH is 6.5 to activate the strains; Bacillus licheniformis, Put the jelly-like Paenibacillus and Bacillus subtilis into the activated medium LB medium (the formula of the LB medium is preferably peptone 10g, sodium chloride 5g, glucose 1.5g, yeast extract powder 5g, add distilled water to make up 1L), The pH is 7.2, and the bacteria are activated; the activated bacteria are inoculated into the corresponding medium for shaking culture, and then fermented in batches in the fermenter. When the total number of microorganisms > 1 × 10 8 When CFU / g, the storage tank collects the bacterial liquid of each strain, seals the storage tank, and stores it under the condition of ambient temperature ≤ 20°C; compound the bacterial liquid of Aspergillus fumigatus and Aspergillus oryzae at a volume ratio of 5:5 Bacterial solution, prepare composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com