Structure for improving mode separation ratio of Fabry-Perot MEMS acceleration sensitive chip

A Fabry Perot, sensitive chip technology, applied in the structural field of improving the modal separation ratio of Fabry Perot MEMS acceleration sensitive chips, can solve the problem of unfavorable cross-axis sensitivity suppression and improvement of modal separation ratio, process Complicated, unable to complete etching at the same time, etc., to achieve the effect of suppressing cross-sensitivity, improving the mode separation ratio, and solving the mutual interference of modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

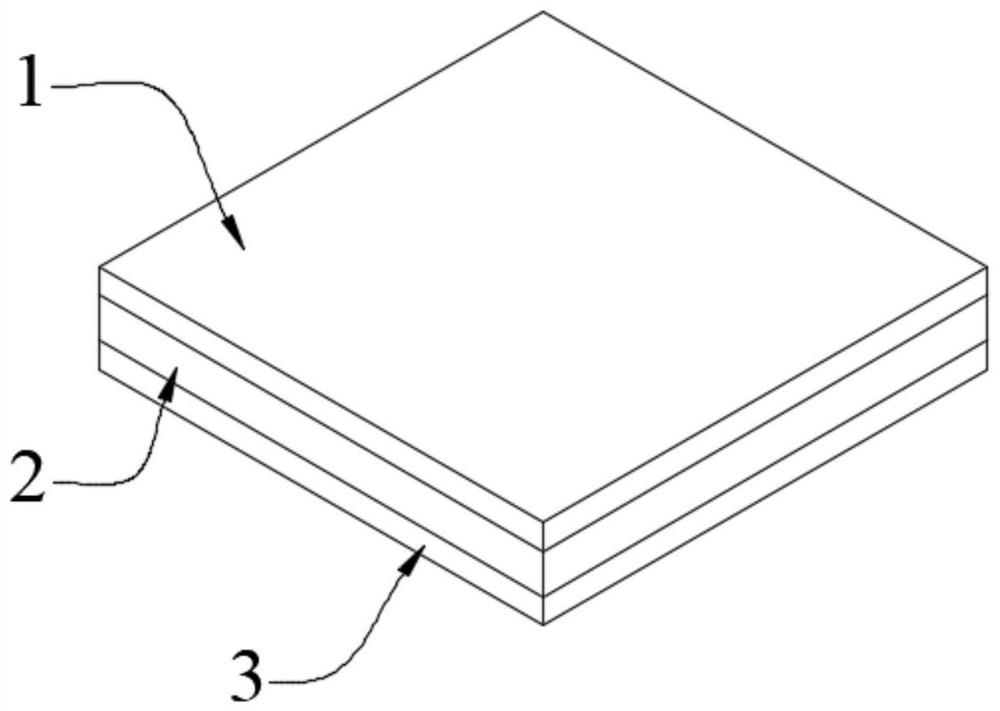

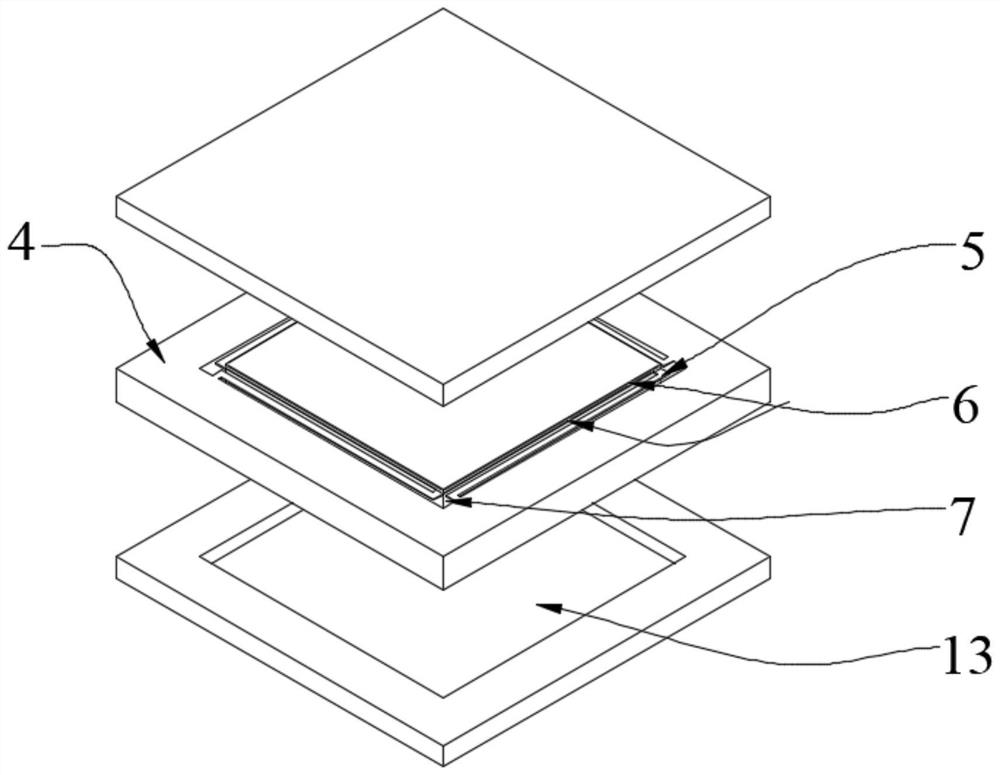

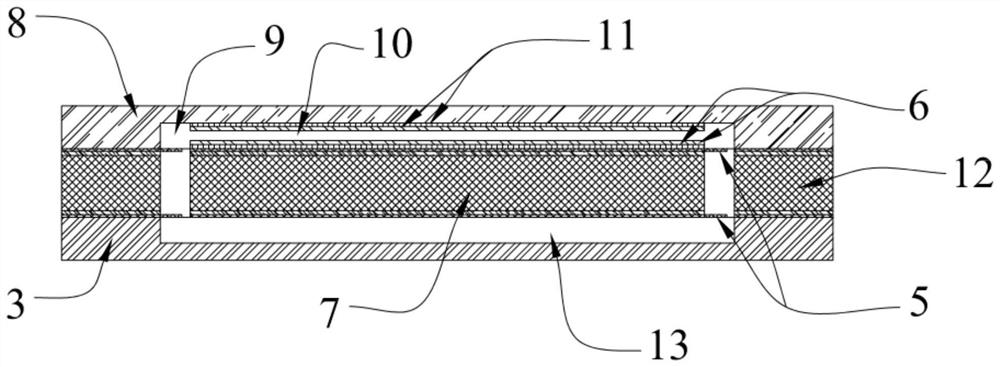

[0035] With the rapid development of micro-nano manufacturing technology and the expansion of market demand, MEMS acceleration sensors are gradually replacing traditional acceleration sensors. The Fabry-Perot optical MEMS acceleration sensor integrates a Fabry-Perot cavity and a MEMS spring-mass structure 12, and introduces optical detection technology into acceleration measurement. It has the advantages of high sensitivity, detection accuracy, and anti-electromagnetic interference.

[0036]Under the existing micro-manufacturing level, how to provide a Fabry-Perot optical MEMS acceleration sensitive chip with high separation ratio of out-of-plane rotation mode and out-of-plane vibration mode, and solve the problem of modal interaction in the measurement process. The problem of interference an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com