FeNi3 composite nitrogen-doped carbon nanotube bifunctional electrocatalyst prepared from biomass

A nitrogen-doped carbon, electrocatalyst technology, applied in fuel cell type half cells and primary cell type half cells, circuits, electrical components, etc., can solve the problem that the catalyst has a single catalytic function, cannot provide catalytic performance, and is disadvantageous to scale Production and other problems, to achieve the effect of improving catalytic performance, facilitating transmission and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] (1) Preparation of corn cob activated carbon: Weigh a certain mass ratio of corn cob and KOH, immerse in ultrapure water for 10–12 h, and freeze-dry; the dried sample is calcined at high temperature for 1.5–2.5 h under the protection of nitrogen ; Grind and pulverize the activated product into 2~4mol·L -1 Magnetically stirred in the HCl solution for 2-6 h, centrifuged, washed with water and alcohol in sequence until neutral, and vacuum-dried the sample at 60-90°C overnight to obtain corn cob activated carbon, denoted as AC-X-Y, where X corresponds to the calcination temperature of 700 ~900℃, Y is the mass ratio of KOH to corn cob 1:2~1:5.

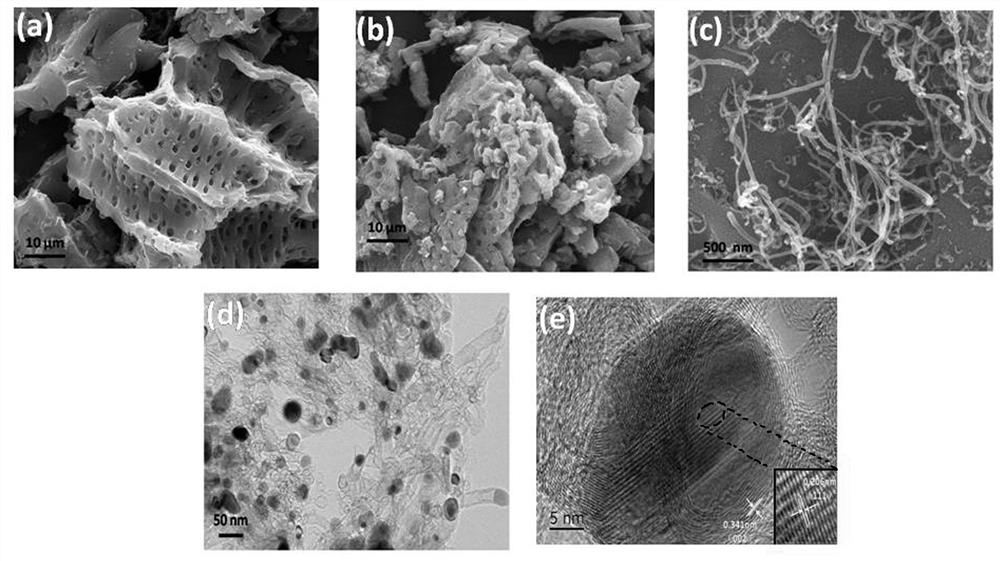

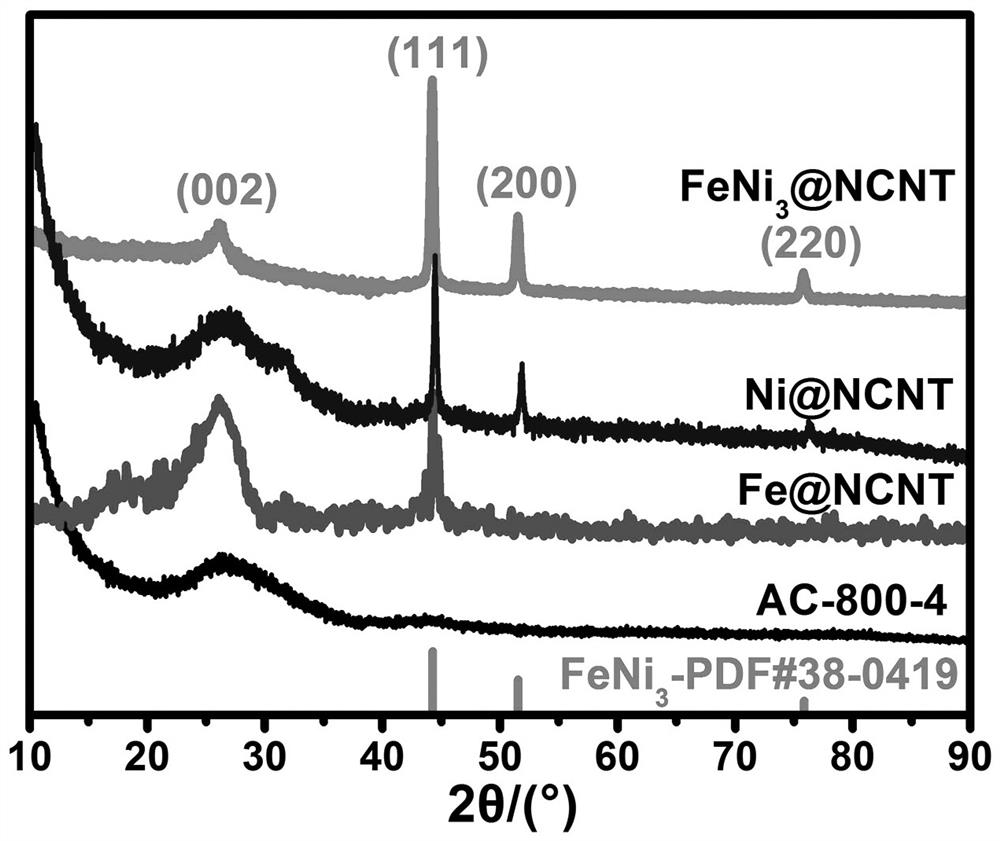

[0036] (2) FeNi 3 Preparation of @NCNT catalyst: take a certain mass ratio of AC, melamine prepared in step (1) and FeCl with a certain concentration ratio 3 •6H 2 O and NiCl 2 •6H 2 O was dissolved in ultrapure water, sonicated at room temperature for 60–80 min, and freeze-dried; 2 In the atmosphere, at 700~1000℃, calcined at ...

Embodiment 1

[0040] A kind of FeNi 3 The preparation method of composite nitrogen-doped carbon nanotube bifunctional catalyst comprises the following steps:

[0041] (1) Preparation of corn cob activated carbon: Weigh 100-mesh corn cob and KOH with a mass ratio of 1:4, dissolve them in 200 mL of ultrapure water, soak the above mixture for 10 h, and collect the product after freeze-drying. in N 2 Under the atmosphere, pyrolyze at 800°C for 2 hours, collect the product, grind it and put it into 3 mol•L -1 Magnetically stirred in the HCl solution for 4 h, centrifuged and washed with water and alcohol until neutral, and the washed sample was vacuum-dried overnight at 80°C to obtain corn cob activated carbon AC-800-4.

[0042] (2) FeNi 3 Preparation of @NCNT catalyst: Take 0.2 g of AC-800-4, 0.8 g of melamine, 0.00258 g of FeCl 3 •6H 2 O and 0.00675 g NiCl 2 •6H 2 O was dissolved in 20 mL ultrapure water, sonicated at room temperature for 60 min, and freeze-dried. in N 2 Under protecti...

Embodiment 2

[0045] (1) Preparation of corn cob activated carbon: Weigh 100-mesh corn cob and KOH with a mass ratio of 1:3, dissolve them in 200 mL of ultrapure water, soak the above mixture for 11 h, freeze-dry it and collect the product. in N 2 Under the atmosphere, pyrolyze at 800°C for 2 hours, collect the product, grind it and put it into 3 mol•L -1 Magnetically stirred in a HCl solution for 5 h, centrifuged and washed with water and alcohol until neutral, and the washed sample was vacuum-dried overnight at 80°C to obtain corn cob activated carbon AC-800-X (X=3).

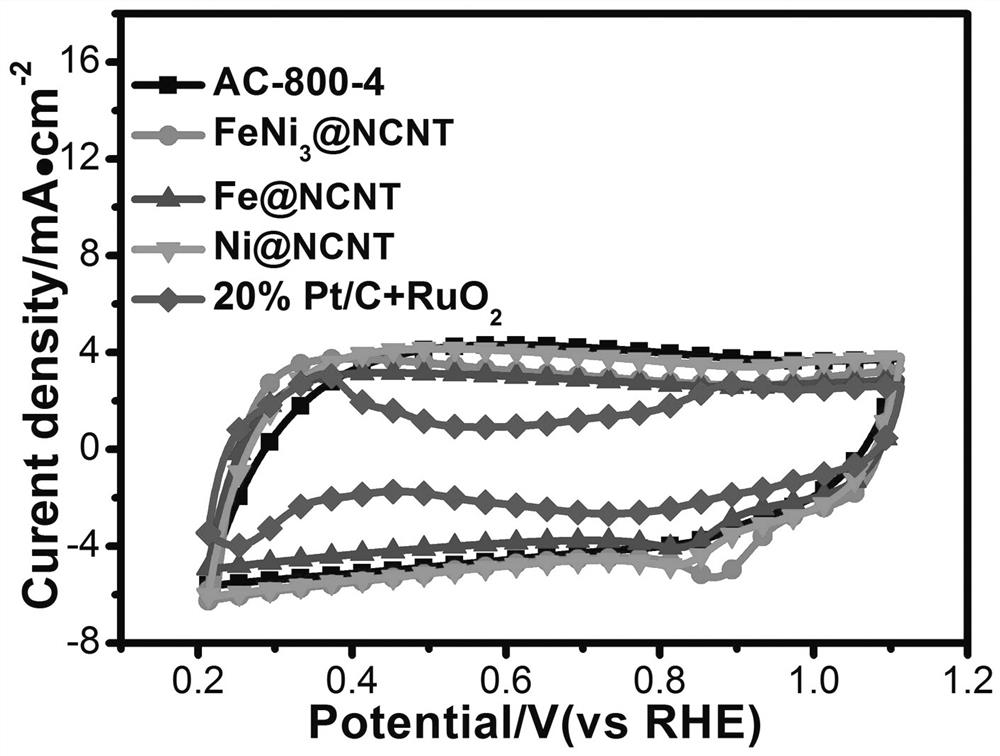

[0046] Take 2 mg of AC-800-X catalyst and disperse in 1 mL of ethanol and 8 μL of 5% Nafion solution, and ultrasonicate for 60 min to obtain a uniformly dispersed suspension. Measure the suspension and drop-coat it on the surface of the glassy carbon electrode with a load of 250 μg / cm 2 , tested after standing for 1h. Using an electrochemical workstation, at 0.1 mol•L -1 The catalyst was tested by linear sweep voltammet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com