Improved process for producing sodium persulfate

A technology of sodium persulfate and ammonium persulfate, applied in the direction of peroxyhydrate/peroxyacid, etc., can solve the problems of sodium persulfate product loss, low purity of sodium persulfate, insufficient crystallization separation, etc., to reduce loss , shorten the reaction time, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

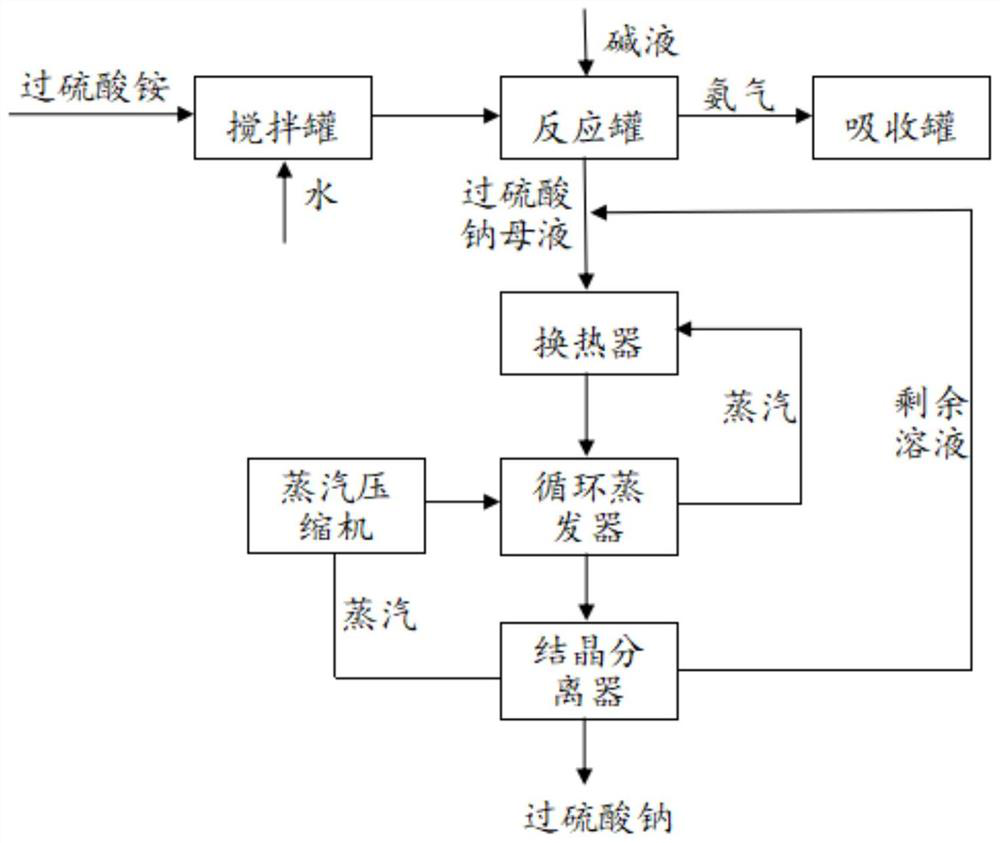

Image

Examples

Embodiment 1

[0028] A kind of improved technique of producing sodium persulfate, comprises the following steps:

[0029] Step 1. Add ammonium persulfate and water into the stirring tank, and after stirring for 20 minutes, the resulting mixture is sent into the reaction tank, and sodium hydroxide solution is added at the same time, raised to the reaction temperature, preheated for 10 minutes, and then reacted at -0.08MPa. Obtain sodium persulfate mother liquor and ammonia gas, wherein, the mass ratio of sodium persulfate, sodium hydroxide is 18:10, and reaction temperature is 30 ℃, and the reaction time is 6h, and ammonium persulfate is the ammonium persulfate after recrystallization treatment, and persulfate The mass ratio of ammonium sulfate and water is 1:1.5, and the mass fraction of sodium hydroxide solution is 46%;

[0030] Step 2, the ammonia gas obtained in step 1 is absorbed through the absorption liquid in the absorption tank, wherein, the absorption liquid is the ammonium persulf...

Embodiment 2

[0034] A kind of improved technique of producing sodium persulfate, comprises the following steps:

[0035] Step 1. Add ammonium persulfate and water into the stirring tank, and after stirring for 20 minutes, the resulting mixture is sent into the reaction tank, and sodium hydroxide solution is added at the same time, raised to the reaction temperature, preheated for 10 minutes, and then reacted at -0.06MPa. Obtain sodium persulfate mother liquor and ammonia gas, wherein, the mass ratio of sodium persulfate and sodium hydroxide is 20:13, reaction temperature 35 ℃, reaction time is 4h, and ammonium persulfate is ammonium persulfate after recrystallization treatment,, The mass ratio of ammonium persulfate and water is 1:2, and the mass fraction of sodium hydroxide solution is 48%;

[0036] Step 2, the ammonia gas obtained in step 1 is absorbed through the absorption liquid in the absorption tank, wherein, the absorption liquid is the ammonium persulfate solution containing sulfu...

Embodiment 3

[0040] A kind of improved technique of producing sodium persulfate, comprises the following steps:

[0041] Step 1. Add ammonium persulfate and water into the stirring tank, and after stirring for 30 minutes, the resulting mixture is sent into the reaction tank, and sodium hydroxide solution is added at the same time, raised to the reaction temperature, preheated for 10 minutes, and then reacted at -0.05MPa. Obtain sodium persulfate mother liquor and ammonia gas, wherein, the mass ratio of sodium persulfate and sodium hydroxide is 22:15, reaction temperature is 45 ℃, reaction time is 3h, ammonium persulfate is ammonium persulfate after recrystallization treatment,, The mass ratio of ammonium persulfate and water is 1:2.5, and the mass fraction of sodium hydroxide solution is 50%;

[0042] Step 2, the ammonia gas obtained in step 1 is absorbed through the absorption liquid in the absorption tank, wherein, the absorption liquid is the ammonium persulfate solution containing sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com