Electrocatalyst based on hexagonal boron nitride nanosheet-reduced graphene oxide composite material and preparation method and application thereof

A technology of hexagonal boron nitride and composite materials, applied in the field of new materials, can solve the problems of low catalytic efficiency, insufficient pure quality of hexagonal boron nitride/reduced graphene oxide composite materials, etc., so as to improve catalytic performance and reduce electron transfer resistance. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

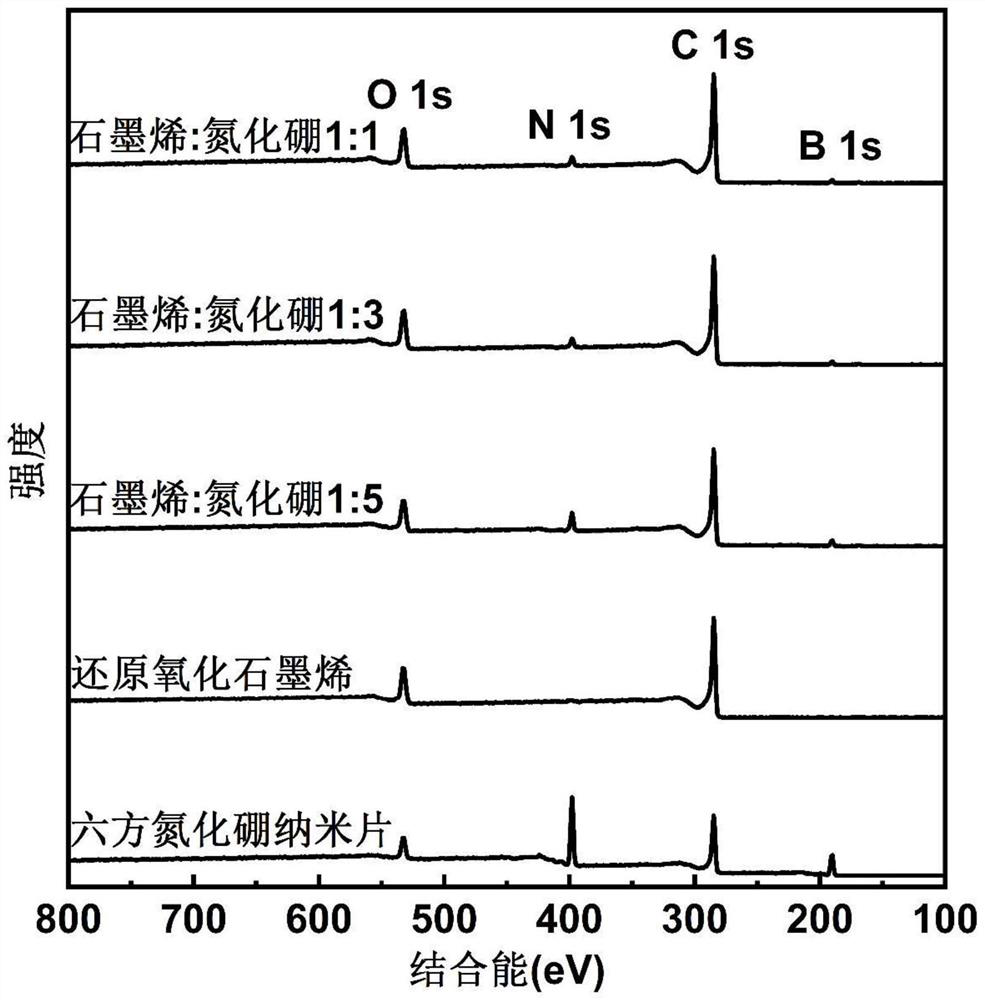

[0032] The present invention proposes a method for preparing an electrocatalyst based on hexagonal boron nitride nanosheet-reduced graphene oxide composite material, comprising the following steps:

[0033] (1) Measure the graphene oxide dispersion (0.5-1 mg / mL diluted in deionized water) and hexagonal boron nitride nanosheet powder respectively, disperse them in deionized water, stir, and ultrasonically treat the stirred dispersion, A dispersion containing few-layer boron nitride nanosheets and graphene oxide is obtained.

[0034] (2) Put the dispersion liquid into a reactor lined with polytetrafluoroethylene, and put it into an oven for reaction. The reacted colloid is put into a freeze dryer and dried to a constant weight to obtain a hexagonal boron nitride nanosheet-reduced graphene oxide composite material.

[0035] (3) fully grinding the hexagonal boron nitride nanosheet-reduced graphene oxide composite material, and ultrasonically dispersing the ground composite materi...

Embodiment 1

[0044] A preparation method based on hexagonal boron nitride-reduced graphene oxide composite material electrocatalyst, comprising the following steps:

[0045] 1. Preparation of hexagonal boron nitride nanosheets:

[0046] (1) Weigh 1 g of hexagonal boron nitride micropowder (with a particle size of 10 μm) and 6 g of potassium permanganate powder, and grind it to mix it evenly;

[0047] (2) 120mL concentrated sulfuric acid (mass concentration is 95%) and 15mL phosphoric acid (mass concentration is 85%) are mixed as reaction solvent;

[0048] (3) Mix 18 mL of hydrogen peroxide (mass concentration: 30%) and 120 mL of deionized water, and freeze the solution for 12 hours;

[0049] (4) Add the mixed powder obtained in step (1) into the mixed acid reaction solvent prepared in step (2), and perform magnetic stirring at 75°C to fully react the powder with the acid. After heating and stirring for 12 hours, add it to In step (3) in the ice cube that hydrogen peroxide and deionized w...

Embodiment 2

[0065] A kind of preparation method based on hexagonal boron nitride-reduced graphene oxide composite electrocatalyst is the same as embodiment 1, the difference is that in step 3, measure graphene oxide dispersion 20ml (concentration is 1mg / ml) and Hexagonal boron nitride nanosheet powder 60mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com