Preparation process and device of polybutylene-1 resin

A preparation process and resin-like technology, which is applied in the field of polymer preparation, can solve the problems of easy agglomeration of polymer output, unsuitable pilot industrial equipment, and difficulty in material transportation, achieving high polymerization efficiency, simplified equipment, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

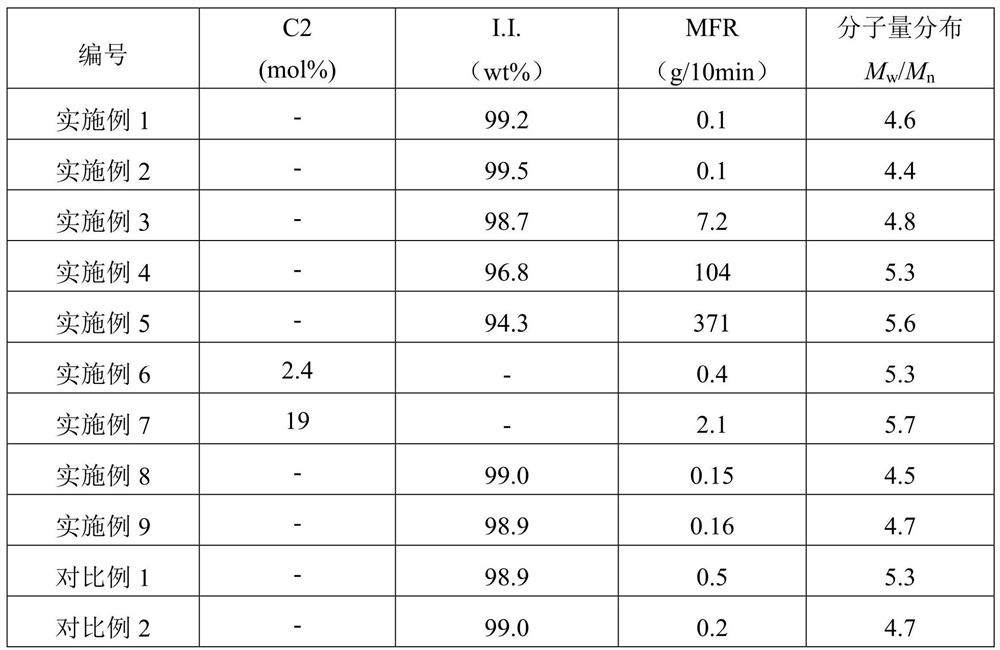

Examples

example

[0029] According to the present invention, the organoaluminum compound component (B) (cocatalyst) can be selected from alkylaluminum compounds having the structural formula AlR n x (3-n), where R is an alkyl, aralkyl or aryl group with 1-20 carbon atoms, X is a halogen, and n is an integer of 0-3. Specifically include but are not limited to the following examples: trimethylaluminum, triethylaluminum, triisobutylaluminum, trihexylaluminum, tri-n-butylaluminum, diethylaluminum monochloride, monoethylaluminum dichloride, dimethylaluminum Aluminum monochloride, diisobutylaluminum monochloride, isobutylaluminum dichloride, tris(2-methyl-3-phenyl-butyl)aluminum, tris(2-phenyl-butyl)aluminum. The organoaluminum compound component (B) may also be selected from aluminum compounds of aluminoxanes, such as methylaluminoxane, tetra(isobutyl)aluminoxane, tetrakis(2,4,4-trimethyl-pentyl ) aluminoxane, tetrakis(2,3-dimethylbutyl)aluminoxane, tetrakis(2,3,3-trimethylbutyl)aluminoxane and th...

Embodiment 1

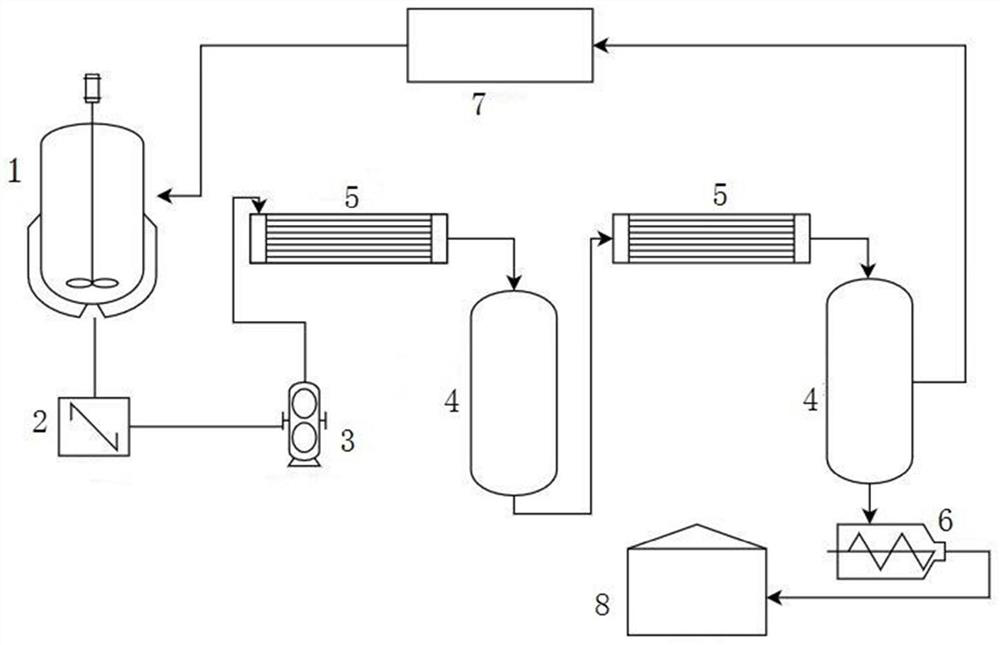

[0057] refer to figure 1, the preparation device of polybutene-1 type resin comprises polymerization reactor 1, mixer 2, conveying booster pump 3 and devolatilization equipment 4 that are arranged in sequence; One is shown); the polymerization reactor is a liquid phase stirred tank reactor, and the devolatilization equipment is provided with two connected in series, and a heat exchanger 5 is arranged before each devolatilization equipment, and the described devolatilization equipment 4 is a flash tank, The polymer melt outlet of the last devolatilization device 4 is connected with the granulation device 6, the butene-1 outlet is connected with the butene-1 recovery device 7, and the material outlet of the granulation device 6 is connected with the silo 8, and The material outlet of the ene-1 recovery device 7 is connected with the polymerization reactor 1 .

[0058] The preparation process of the polybutene-1 type resin of this embodiment comprises: main catalyst is prepared ...

Embodiment 2

[0063] The catalyst used in embodiment 2, pre-complexation, polymerization process conditions are identical with embodiment 1. The difference from the examples is that the antioxidant 1135 is selected as the antioxidant added during mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com