Doped carbon material, platinum-carbon catalyst and preparation method and application of platinum-carbon catalyst

A platinum-carbon catalyst and carbon material technology, applied in the field of doped carbon materials, can solve the problems of uneven dispersion of platinum nanoparticles, performance degradation of platinum-carbon catalyst, accelerated carbon corrosion reaction, etc., and achieve excellent comprehensive catalytic performance and excellent carbon resistance. Corrosion ability, the effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0152] The invention provides a preparation method of platinum carbon catalyst, comprising:

[0153] (1) The steps of manufacturing carbon carrier: first contact the carbon material with phosphorus source and boron source, and treat it in inert gas at 300 ℃ ~ 800 ℃ for 0.5h ~ 10h; Then, contact with the sulfur source and treat it in inert gas at 400 ℃ ~ 1000 ℃ for 0.5h ~ 10h to obtain the carbon carrier;

[0154] (2) The step of loading platinum with the carbon carrier obtained in (1).

[0155] According to the preparation method of the platinum carbon catalyst of the invention, in (1), "the contact mode between the carbon material and the sulfur source, phosphorus source and boron source" is the same as the corresponding part in the previous text, which will not be repeated in the invention.

[0156] According to the preparation method of the platinum carbon catalyst of the invention, the sulfur source is elemental sulfur.

[0157] According to the preparation method of the plati...

Embodiment 1

[0192] The embodiment is used to illustrate the preparation of sulfur phosphorus boron doped carbon material of the invention.

[0193] Immerse 1g Vulcan XC72 in 15ml aqueous solution with sodium borate concentration of 2.0wt% and phosphoric acid concentration of 0.5wt% for 24h; Drying in an oven at 100 ℃; Then put it into the tubular furnace and raise the temperature of the tubular furnace to 450 ℃ at the rate of 5 ℃ / min for 2h; Boron and phosphorus doped carbon materials were obtained after natural cooling.

[0194] Mix the boron phosphorus doped carbon material with 0.167g elemental sulfur evenly, put it into the tubular furnace, and heat the tubular furnace to 700 ℃ at the rate of 5 ℃ / min for constant temperature treatment for 3h; After natural cooling, sulfur boron phosphorus doped carbon material is obtained, which is numbered as carbon carrier a.

[0195] Sample characterization and testing

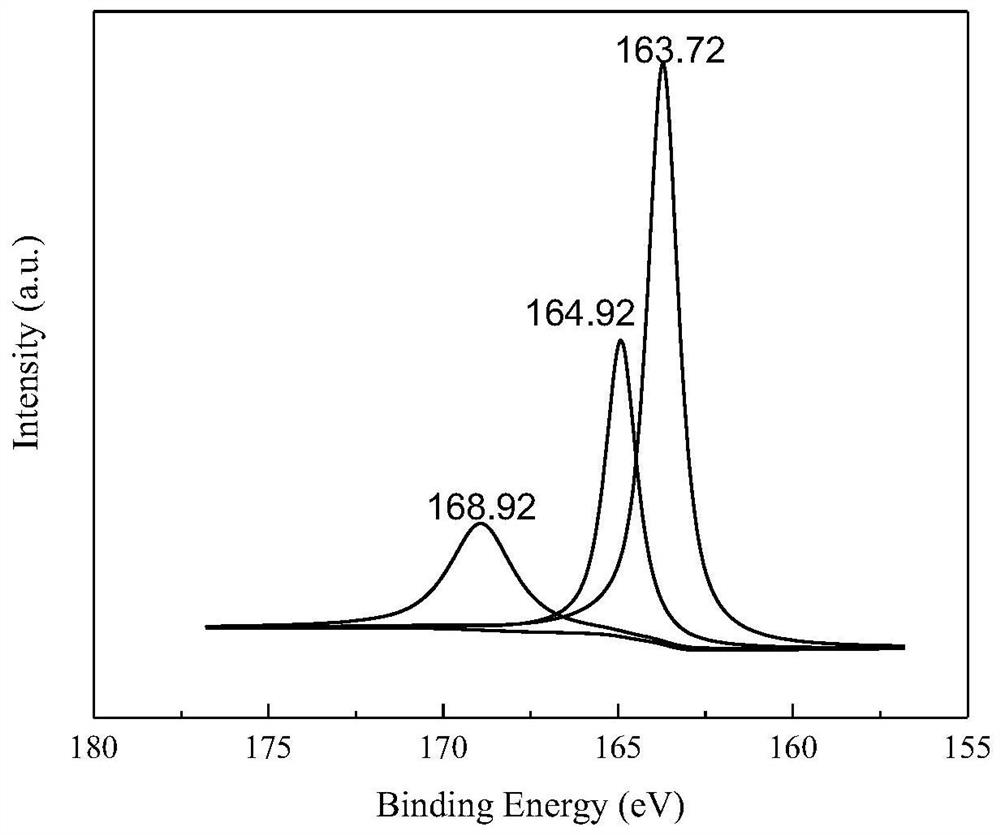

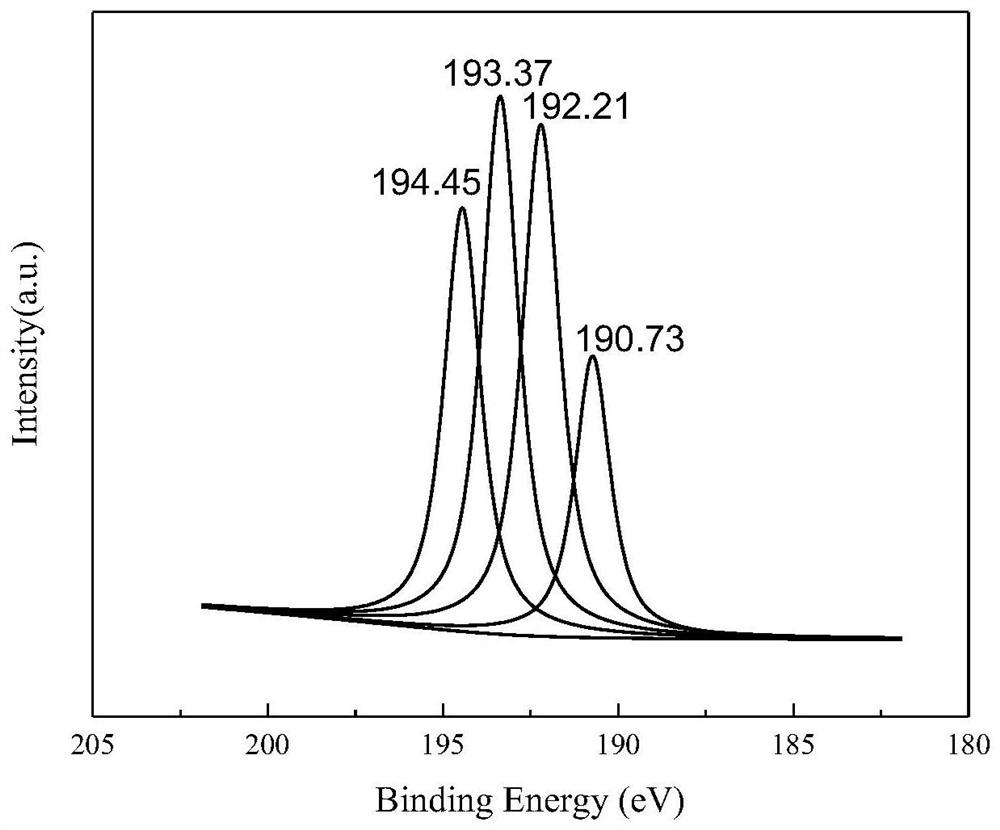

[0196] The mass fraction of sulfur analyzed by XPS is 0.8%; The mass fraction ...

Embodiment 2

[0202] The embodiment is used to illustrate the preparation of sulfur phosphorus boron doped carbon material of the invention.

[0203] Add 10ml absolute ethanol to 1g ketjenblack ecp600jd, and then add 25ml aqueous solution with boric acid concentration of 0.4wt% and sodium phosphate concentration of 2.0wt% for immersion for 24h; Drying in an oven at 100 ℃; Then put it into the tubular furnace and raise the temperature of the tubular furnace to 700 ℃ at the rate of 5 ℃ / min for 2h; Boron and phosphorus doped carbon materials were obtained after natural cooling.

[0204] Mix the boron phosphorus doped carbon material with 0.25g elemental sulfur evenly, put it into the tubular furnace, and heat the tubular furnace to 400 ℃ at the rate of 5 ℃ / min for constant temperature treatment for 3h; After natural cooling, sulfur boron phosphorus doped carbon material is obtained, which is numbered as carbon carrier B.

[0205] Sample characterization and testing

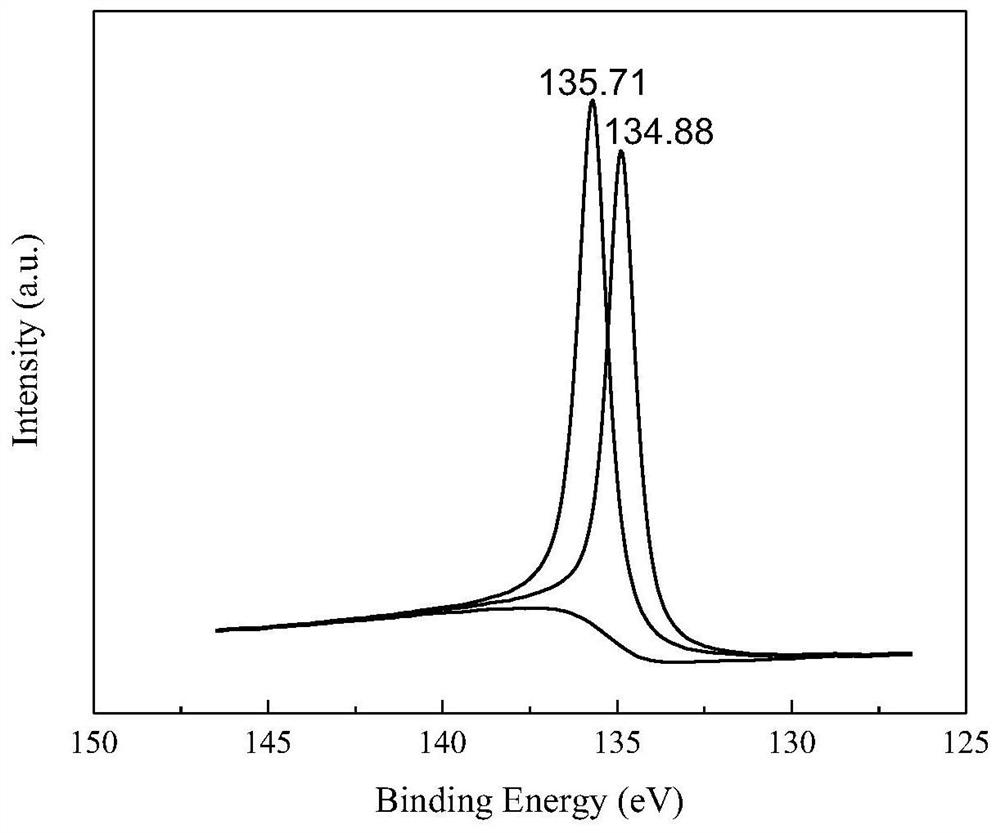

[0206] The mass fraction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com