Full-quantitative treatment method for kitchen garbage

A kitchen waste quantitative treatment technology, which is applied in the field of full quantitative treatment of kitchen waste, can solve the problems of low calorific value of incineration, high oil and salt content, and perishability, so as to improve specific surface area and microporosity, improve Yield and calorific value, effect of organic matter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

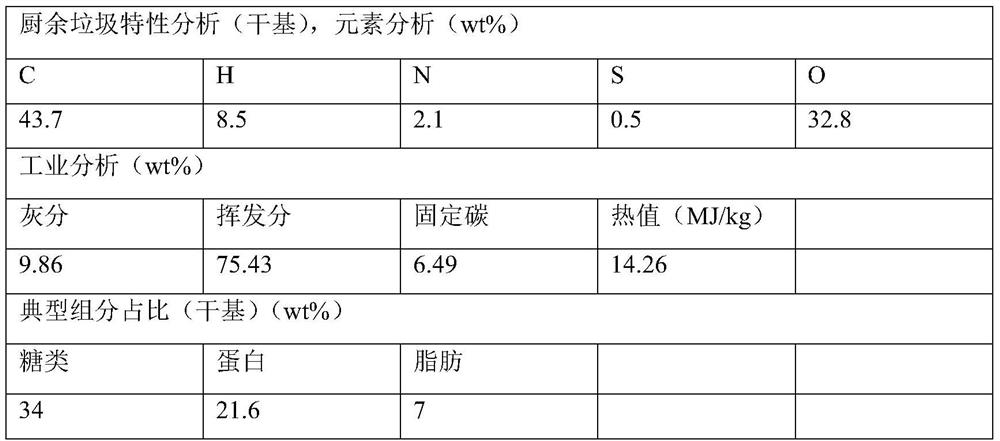

[0081] Example 1: Quantitative treatment method of kitchen waste

[0082]Fresh mixed kitchen waste (water content > 90%) is supplemented with distilled water according to 6 times the solid content (that is, the dry weight of fresh mixed kitchen waste) in the sealed hydrothermal carbonization reactor. For carbonization reaction, the amount of materials added is 70-80% of the volume of the reaction kettle, the stirring speed is 120 rpm, and the temperature is raised to 200° C., and kept for 1 hour. During the first hydrothermal carbonization reaction, no catalyst was added, and no other gas was introduced, and the hydrothermal carbonization reaction was carried out by the pressure generated by itself after the materials in the reactor were heated. After the first hydrothermal carbonization reaction ends, the first hydrothermal carbonization liquid-phase working medium is filtered and separated from the first hydrothermal carbon, and the first hydrothermal carbonization liquid-ph...

Embodiment 2

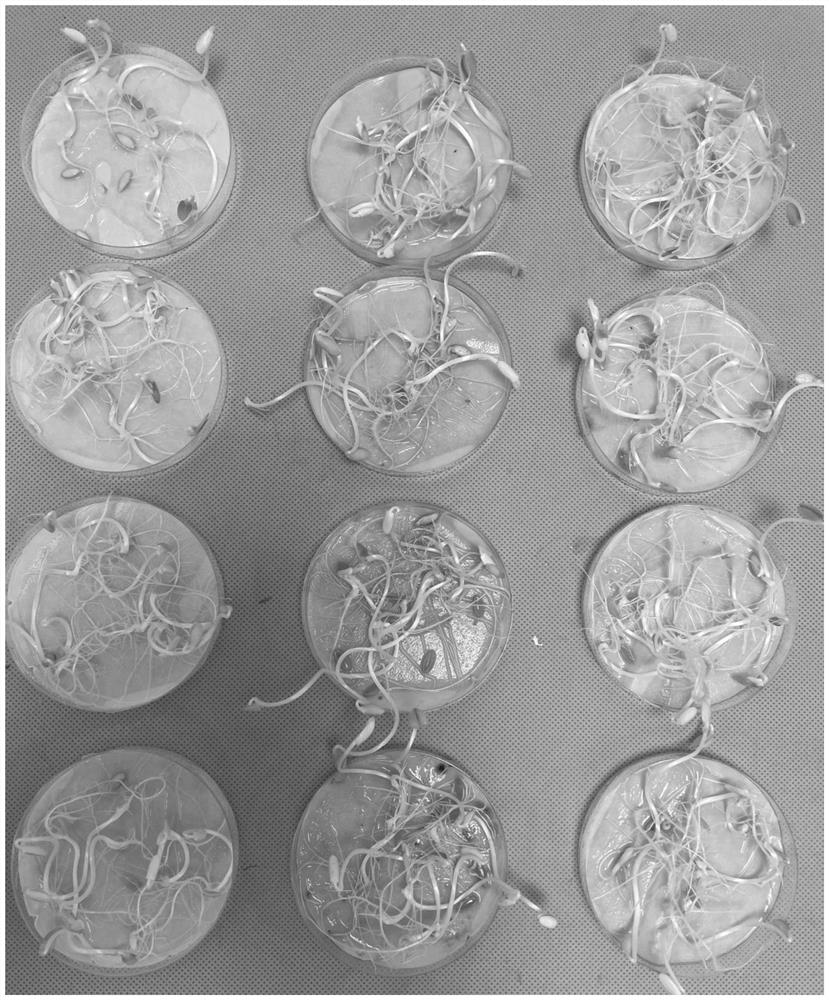

[0085] Embodiment 2: biochar-based organic fertilizer

[0086] In this example, the raw materials of the biochar-based organic fertilizer include: 100 kg of the liquid-phase product obtained in Example 1, 15 kg of activated hydrothermal carbon, and 0.5 kg of humic acid fertilizer.

[0087] Preparation process: Mix all the components in proportion. After the activated hydrothermal carbon and humic acid fertilizer fully absorb the liquid phase product, dry the mixture at 105 degrees until the moisture content of the mixture is about 50%. Use a disc The granulator performs granulation to form uniform granules with a particle size of 3-5mm. The composition ratio of the biochar-based organic fertilizer prepared in this embodiment is as follows:

[0088] components Content (wt%) Total nutrients (N+P 2 o 5 +K 2 O) mass fraction (based on drying basis)

[0089] The prepared biochar-based organic fertilizer has the nutrients required by the soil and the slow-rel...

Embodiment 3

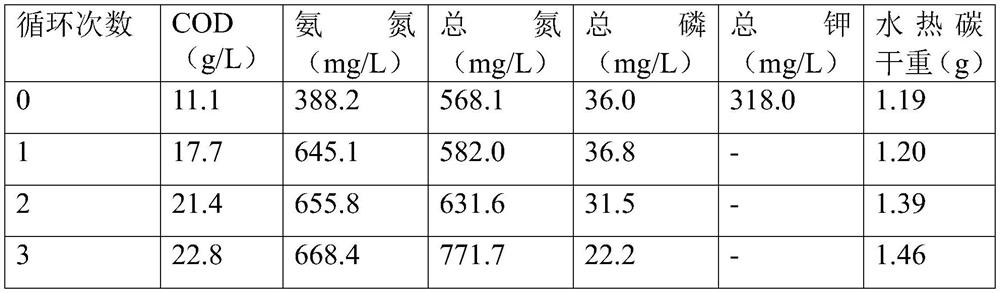

[0090] Embodiment 3: Circulation treatment is to the enrichment effect of nutrient component in the treatment liquid

[0091] Experiment (1)

[0092] Using 50g fresh weight of mixed kitchen waste (water content>90%) similar to Example 1 above, add 100mL of water for the first time, and hydrothermal carbonization reaction occurs in a sealed hydrothermal carbonization reaction kettle, stirring speed 300rpm, Raise the temperature to 200°C and keep it warm for 1 hour, which is recorded as cycle 0; after the reaction is completed, filter, take 100 mL of the filtrate and add 50 g of the same vegetable kitchen waste, and carry out the hydrothermal carbonization reaction under the same treatment conditions as above, which is recorded as cycle 1 times; repeat the cycle in this way, a total of 3 cycles. The components of the treatment liquid and the weight of the dry hydrothermal carbon were tested separately, and the results are as follows:

[0093]

[0094]

[0095] The above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com