Waste heat recovery device for white carbon black production

A technology of waste heat recovery device and white carbon black, which is applied in the direction of indirect heat exchanger, heat exchanger type, heat exchange equipment, etc., can solve the problem of not complying with energy saving and environmental protection policies, failing to improve the technical level of production technology and the economic benefits of enterprises , heat can not be fully utilized and other issues, to achieve the effect of reducing energy waste, speeding up cooling speed, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

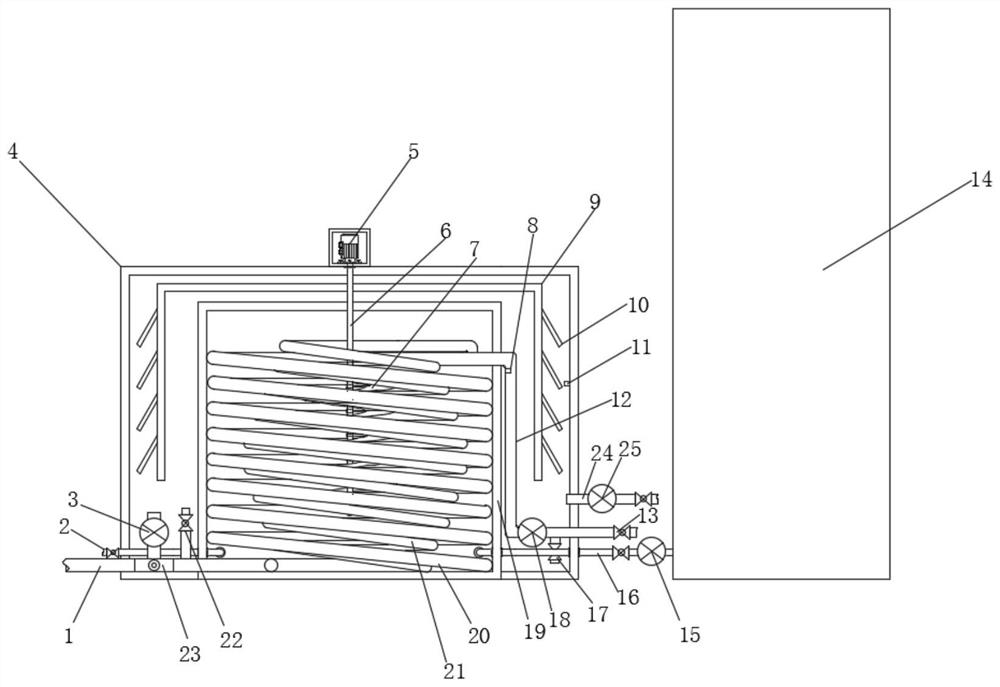

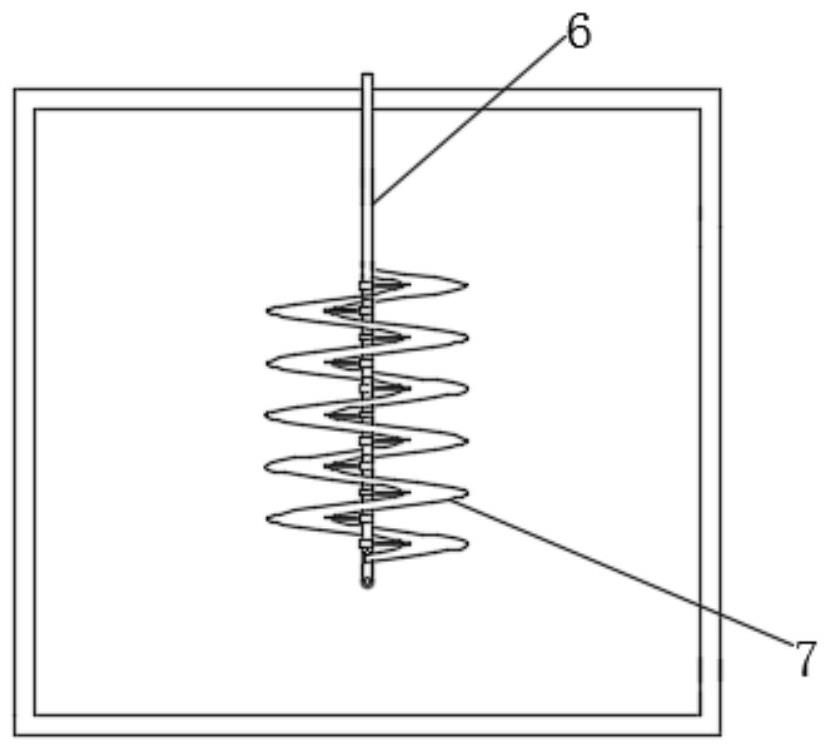

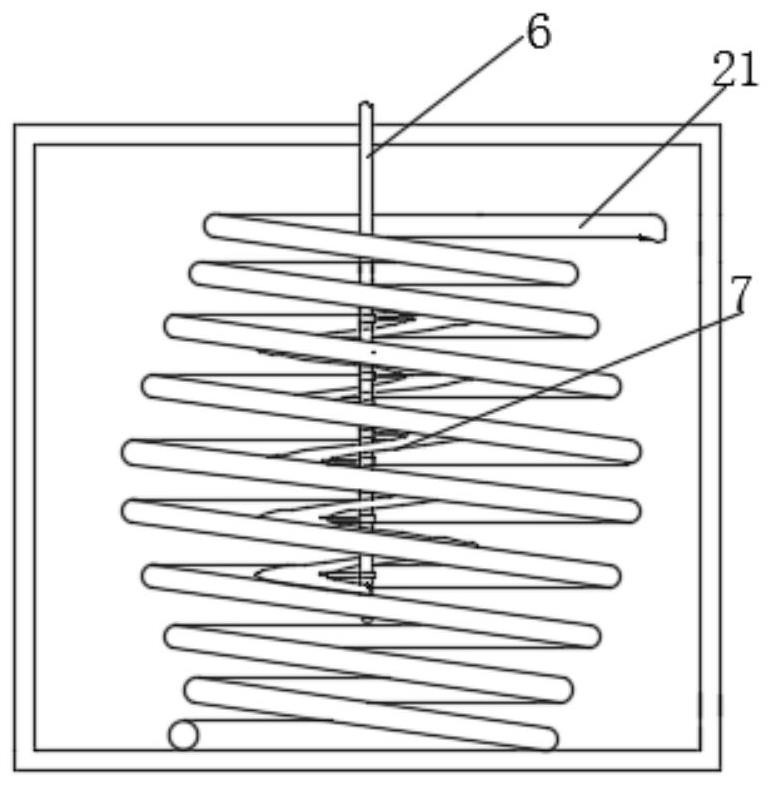

[0025] A waste heat recovery device for white carbon black production, comprising a second cylinder 19, the inner wall of the second cylinder 19 is provided with a first coil 20, and the first coil 20 spirals up around the inner wall of the second cylinder 19, The lower port of the first coil 20 is connected with the water inlet pipe 1, and the bottom of one side of the second cylindrical body 19 is connected with the liquid inlet pipe 16, and one end of the liquid inlet pipe 16 is connected with the reaction tower 14. During the liquid time, there is a second water pump 15 in the middle of the liquid inlet pipe 16, and a valve is arranged on the liquid inlet pipe 16; the reaction tower 14 is equipped with heated and dissolved liquid natron, and the bottom of the other side of the second cylinder 19 is connected with a The liquid outlet pipe 2 is provided with a valve on the liquid outlet pipe 2, the second coil pipe 21 is arranged inside the first coil pipe 20, the upper part ...

Embodiment 2

[0029] As an optional situation, a waste heat recovery device for white carbon black production, a first cylinder 4 is arranged outside the second cylinder 19, in order to ensure the thermal insulation performance of the first cylinder 4, the internal heat is not easily Dissipate, make full use of the heat, the outside of the first cylinder 4 is provided with an insulation layer, the outside of the second cylinder 19 and the first cylinder 4 form a housing cavity, and the first water outlet pipe 12 is arranged in the housing chamber, and the first water outlet pipe 12, one end is connected to the water outlet end of the second coil pipe 21, the other end of the first water outlet pipe 12 passing through the first cylinder 4 is provided with a first valve 13, and the middle part of the first water outlet pipe 12 is provided with a third water pump 18, and the first outlet pipe 12 is provided with a third water pump 18. The lower end of the water pipe 12 in the accommodating cham...

Embodiment 3

[0036] As an optional situation, a waste heat recovery device for white carbon black production, the device is controlled by a PLC control system, the input and output of each signal is controlled by the control system, and the input signal of the first temperature sensor 8 is transmitted to the control system. When the temperature of warm water is required, the output signal of the control system controls the opening of the first valve 13, and the warm water is directly pumped away; when the temperature of the warm water is lower or higher than the required temperature, the output signal of the control system controls the first valve 13 to close, and the second The valve 17 is opened, when the temperature of warm water is lower than the required temperature, the control system output signal controls the water inlet of the three-way valve 23 to close, and the third valve 22 opens until the temperature detected by the second temperature sensor 11 reaches the required temperature,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap