Trimethylsilyl compound, electrolyte and lithium ion battery

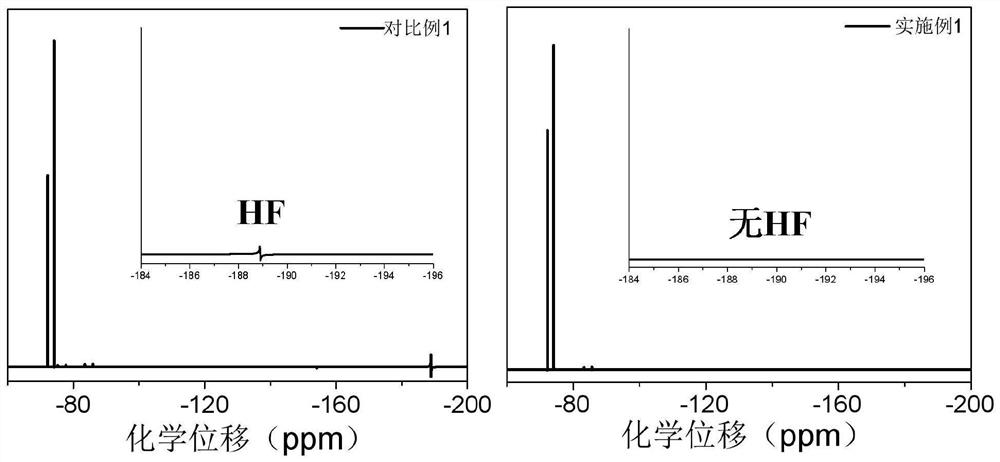

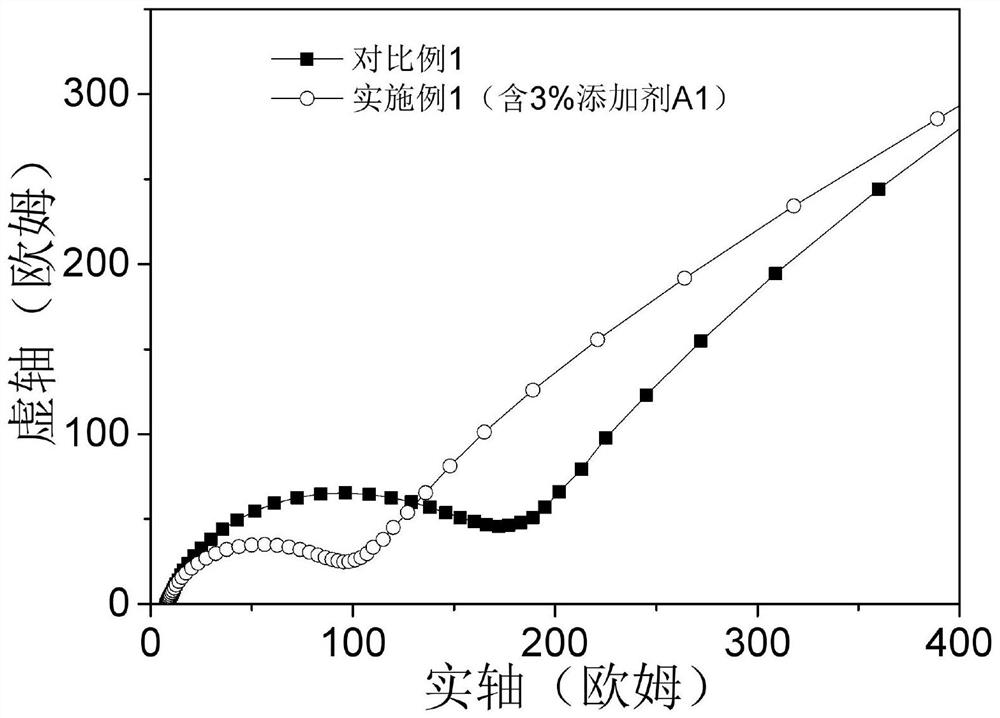

A technology of trimethylsilyl and electrolyte, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of no obvious effect of HF generation and large interface film impedance, so as to suppress side reactions, avoid reactions, Effect of improving long-term cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

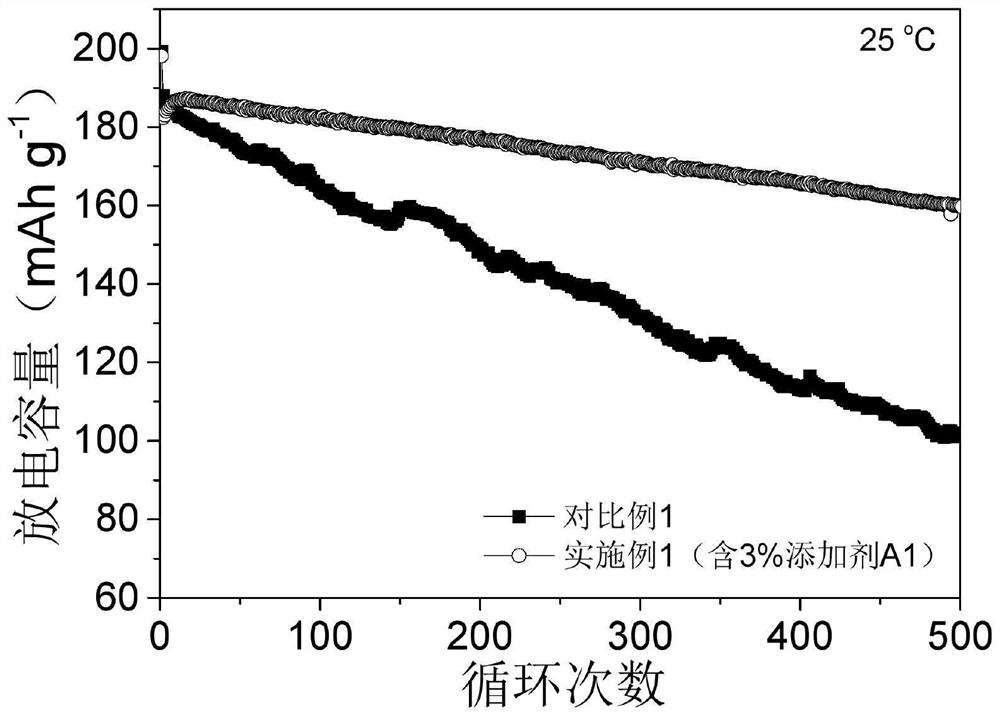

Embodiment 1

[0046] Preparation of initial electrolyte: in a glove box filled with argon (H 2 O99.99%), mix ethylene carbonate, dimethyl carbonate and ethyl methyl carbonate at a volume ratio of 1:1:1, and then dissolve lithium hexafluorophosphate in it at a concentration of 1mol / L to obtain the initial electrolyte.

[0047]Preparation of the electrolyte solution: adding the trimethylsilyl compound having the structural formula A1 to the initial electrolyte solution at a mass fraction of 3% to obtain the electrolyte solution.

[0048] Assembly of lithium-ion full battery: positive electrode LiNi 0.8 co 0.1 mn 0.1 o 2 The pole piece and the negative pole are made of artificial graphite pole piece, and the positive and negative pole pieces are made through processes such as slurry stirring, coating, drying, rolling, slicing, and vacuum drying, and the above-mentioned electrolyte is added to package the battery. The battery is subjected to a constant current charge and discharge test at ...

Embodiment 2

[0055] In this example, the electrolyte is prepared according to the method of Example 1, the difference is that the trimethylsilyl compound in this example is a trimethylsilyl compound with the A3 structural formula; when assembling a lithium-ion full battery, use LiNi 0.5 co 0.2 mn 0.3 o 2 Positive plate replaces LiNi 0.8 co 0.1 mn 0.1 o 2 pole piece.

[0056] The reversible specific capacity of the battery prepared in Example 2 during long-term cycle is as follows: Image 6 shown.

Embodiment 3

[0058] In this example, the electrolyte is prepared according to the method of Example 1, the difference is that the trimethylsilyl compound in this example is a trimethylsilyl compound with the A6 structural formula; when assembling a lithium-ion full battery, use LiNi 0.6 co 0.2 mn 0.2 o 2 Positive plate replaces LiNi 0.8 co 0.1 mn 0.1 o 2 pole piece.

[0059] The reversible specific capacity of the battery prepared in embodiment 3 during long-term cycle is as follows: Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com