High-specific-volume porous electrode foil and preparation method thereof

A porous electrode, high-ratio technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of unsatisfactory thermal treatment effect, limited application, difficult to form a stable molten structure, etc. The effect of reducing capacity and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

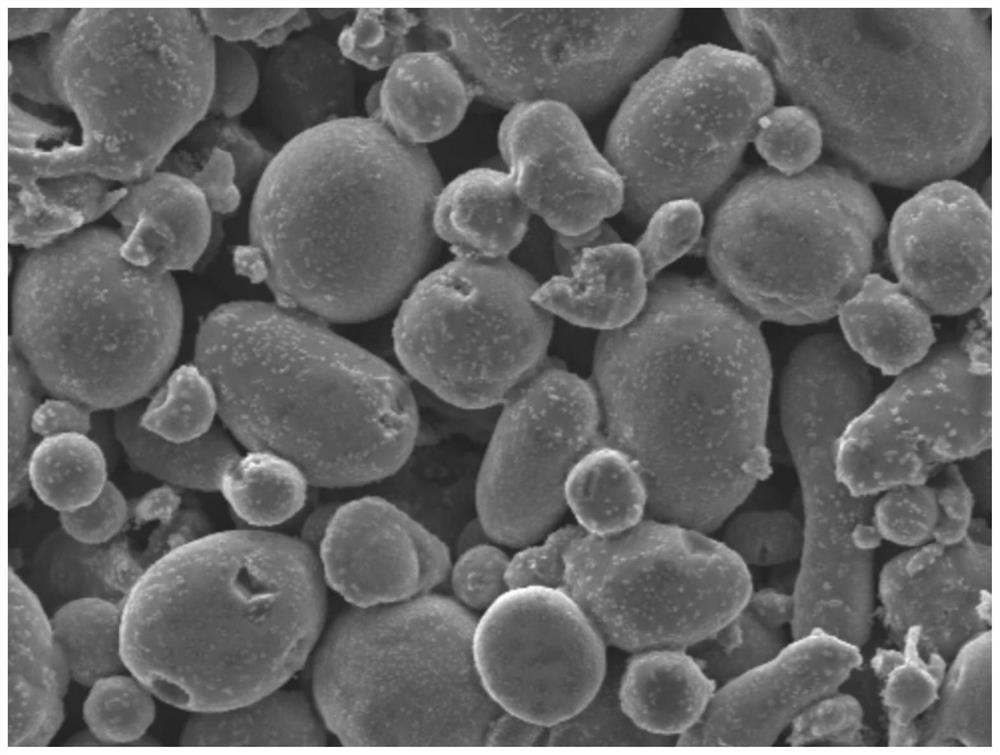

Image

Examples

Embodiment 1

[0062] In this embodiment, a method for preparing a high specific volume porous electrode foil includes the following steps:

[0063] (1) Mix aluminum powder, valve metal oxide powder, aluminum-silicon alloy powder, binder and solvent according to a preset mass ratio to obtain a mixed fluid;

[0064] Specifically, aluminum powder with an average particle size of 3 μm, titanium dioxide powder with an average particle size of 100 nm, aluminum-silicon alloy powder with an average particle size of 500 nm (silicon content is 11.7w t.%), polyvinylidene fluoride and N- Methylpyrrolidone is mixed to obtain a mixed fluid;

[0065] Among them, the mass ratio of titanium dioxide powder to aluminum powder is 1:20; the mass ratio of aluminum-silicon alloy powder to aluminum powder is 1:100, and the mass ratio of polyvinylidene fluoride to aluminum powder is 1:100; the solid content of the mixed fluid 60%;

[0066] (2) coating the mixed fluid on at least one side of the aluminum foil subs...

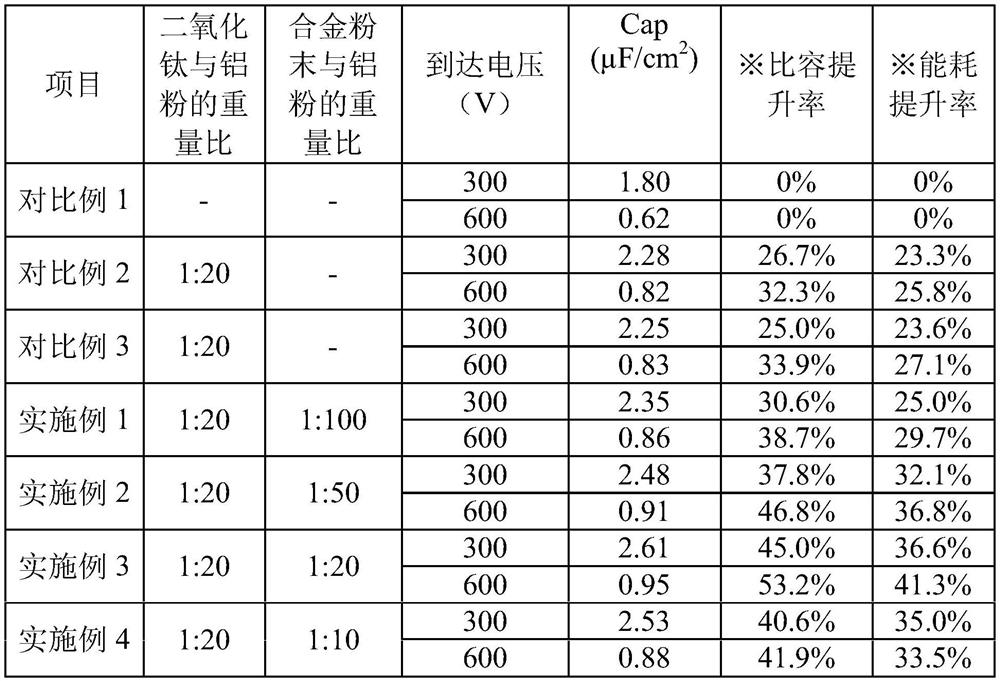

Embodiment 2-4

[0072] The preparation method of the high specific volume porous electrode foil of Examples 2-4 is basically the same as that of Example 1, except that in step (1), the mass ratio of aluminum-silicon alloy powder to aluminum powder is adjusted to 1:50, 1 :20, 1:10.

Embodiment 5-8

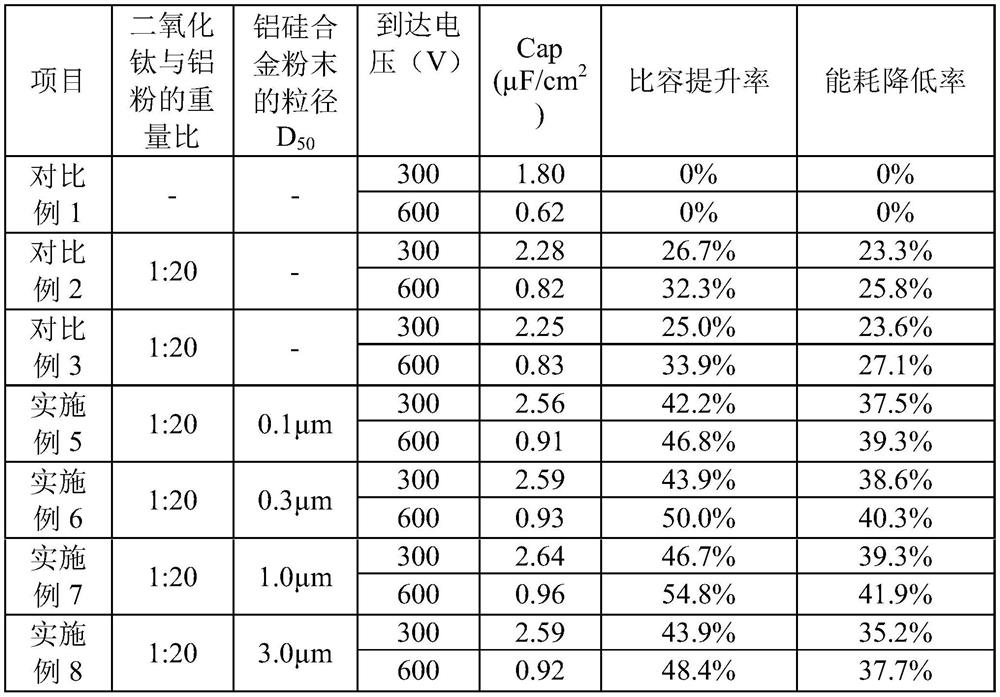

[0093] The preparation process of the porous electrode foil of Examples 5-8 is basically the same as that of Example 3, except that:

[0094] The average particle diameters of the aluminum-silicon alloy powders were adjusted to 0.1 μm, 0.3 μm, 1.0 μm, and 3.0 μm, respectively.

[0095] According to the SJ / T 11140-1997 standard, the porous electrode foils prepared in Examples 5-8 were tested for performance, and the test results are shown in Table 2.

[0096] Table 2

[0097]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com