Biodegradable environment-friendly lubricating oil and preparation method thereof

A biodegradable, lubricating oil technology, applied in lubricating compositions, petroleum industry, rayon manufacturing, etc., can solve the problems of poor biodegradability and low anti-wear performance, and achieve the effect of improving viscosity coefficient and high biodegradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A biodegradable and environmentally friendly lubricant that includes the following components:

[0031] 2wt% chitin-polyurethane fiber, 0.5wt% antiemulsifier, 2.2wt% antioxidant, 1.2wt% rust inhibitor, 1.3wt% dispersant, 1.2wt% defoamer, residual plant mixed base oil.

[0032] Among them, the anti-emulsifier is the anti-emulsifier T1001, the antioxidant is di-tert-butyl-p-cresol, the rust inhibitor is sodium sulfonate, the dispersant is polyisobutene monosorcinimide, and the defoamer is methyl silicone oil.

[0033] The vegetable base oil is canola oil and castor oil mixed in a 2:1 mass ratio.

[0034] The chitin - polyurethane fiber preparation method comprises the following steps:

[0035] (1) The polyurethane material is dissolved in an organic solvent to form a polyurethane solution, and the concentration of the polyurethane solution is 10wt%;

[0036] (2) Add 4wt% chitin whiskers in polyurethane solution, stir evenly to form a spinning solution, stir at a speed of 800 ...

Embodiment 2

[0048] A biodegradable environmentally friendly lubricant, compared with Example 1, the difference is that the use of chitin powder added to the polyurethane solution to form a spinning solution, the remaining steps and components are the same as Example 1.

[0049] Control group 1

[0050] A biodegradable environmentally friendly lubricating oil, compared with Example 1, the difference is that the composition content is not added chitin - polyurethane fiber, the remaining steps and components are the same as Example 1.

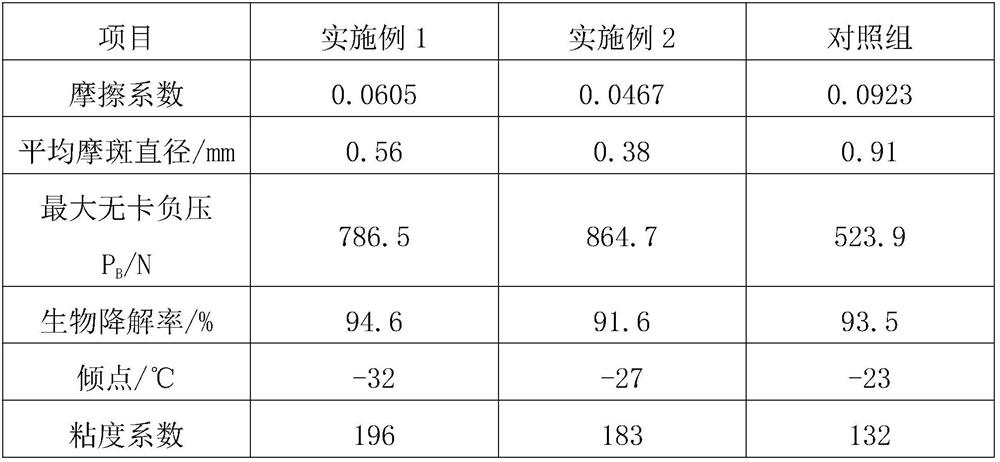

[0051] Example 1-2 and the control group produced environmentally friendly lubricants for performance testing.

[0052]1. Use four-ball friction and wear testing machine, load 392N, test 60min, oil pool lubrication, test steel ball for 12.7mmGCr15 standard steel ball, test the friction coefficient and average mold diameter of environmentally friendly lubricating oil, and determine the bearing performance of lubricant according to the four-ball method of GB / T3142-...

Embodiment 3

[0061] A biodegradable and environmentally friendly lubricant that includes the following components:

[0062] 3wt% chitin-polyurethane fiber, 0.5wt% antiemulsifier, 2.5wt% antioxidant, 1.5wt% rust inhibitor, 1.5wt% dispersant, 1.5wt% defoamer, residual plant mixed base oil.

[0063] Among them, the anti-emulsifier is the anti-emulsifier T1001 and the anti-emulsifier D114 mixed, the antioxidant is, thiophosphate dioctyl zinc salt, the rust inhibitor is a mixture of polymer carboxylic acid and phosphate, the dispersant is calcium petroleum sulfonate and magnesium petroleum sulfonate, and the defoamer is methyl silicone oil.

[0064] The vegetable base oil is a mixture of rapeseed oil and castor oil in a mass ratio of 2:1.5.

[0065] The remaining preparation methods and steps are the same as in Example 1.

[0066]The environmentally friendly lubricating oil prepared by this embodiment is tested for four-ball friction wear and biodegradation, the friction coefficient measured by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com