Carbide-loaded noble metal monatomic catalyst and preparation and application thereof

A precious metal and catalyst technology, applied in the field of preparation of carbide-supported precious metal single-atom catalysts, can solve the problems of difficulty in exposing electrochemically active sites, affecting hydrogen production activity and stability, harsh preparation process conditions, etc. The effect of distribution, high specific surface area, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 01-12

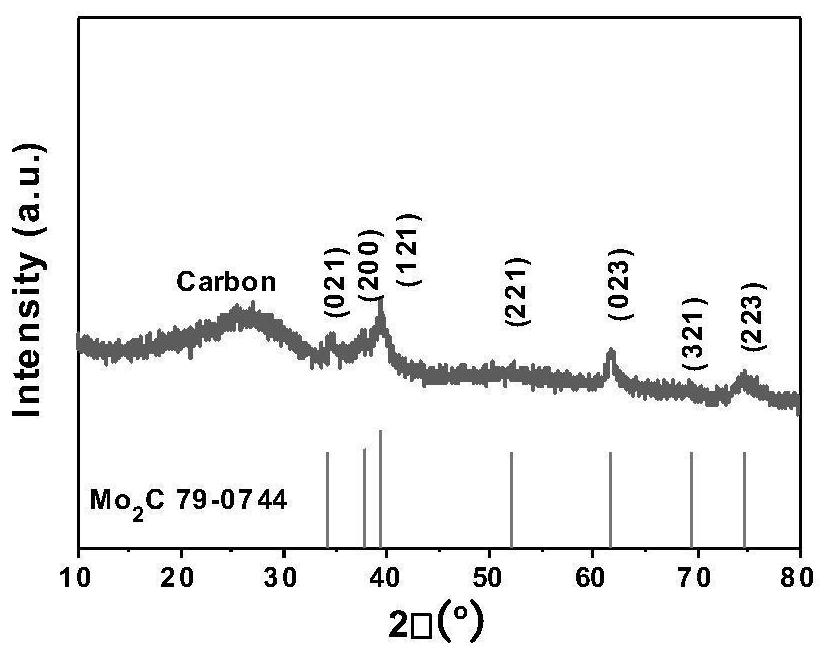

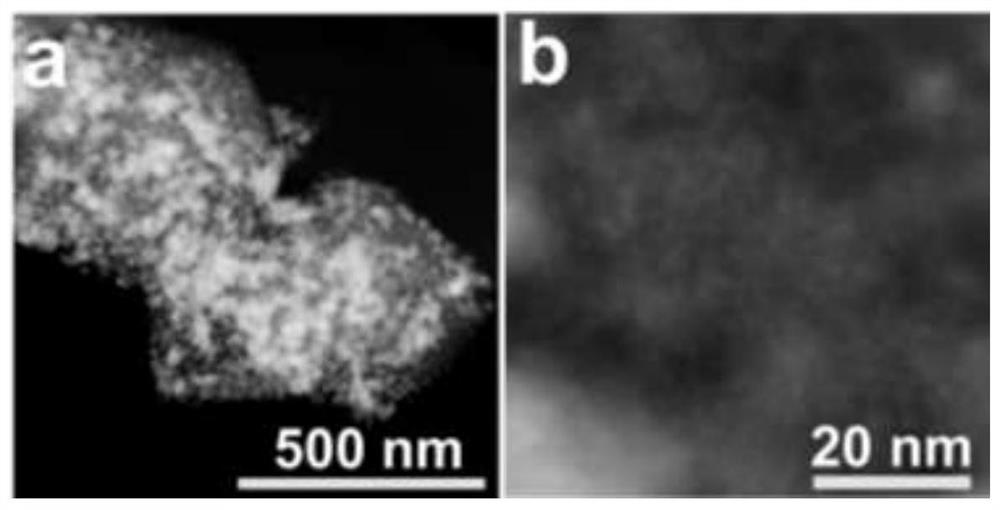

[0030] Example 01-12 Preparation method of platinum single-atom catalyst supported by molybdenum carbide with Pt-NENU-5 as precursor

[0031] 1) Mix a certain quality of phosphomolybdic acid, 0.3 g of copper acetate, 0.1 g of glutamic acid, 0.2 g of trimesic acid, and a certain quality of chloroplatinic acid, and stir to obtain a Pt-NENU-5 precursor;

[0032] 2) Heat treatment of the Pt-NENU-5 precursor obtained in 1) in a tube furnace at 2°C for min -1 The heating rate was raised to 800 °C, calcined under argon atmosphere for 6 h, and then naturally lowered to room temperature;

[0033] 3) Disperse the catalyst obtained in 2) in 0.5M H 2 SO 4 , stirred at 50 °C for 1 h to obtain Pt 1 -Mo 2 Table 1 shows the amount of C-C catalyst, phosphomolybdic acid and chloroplatinic acid.

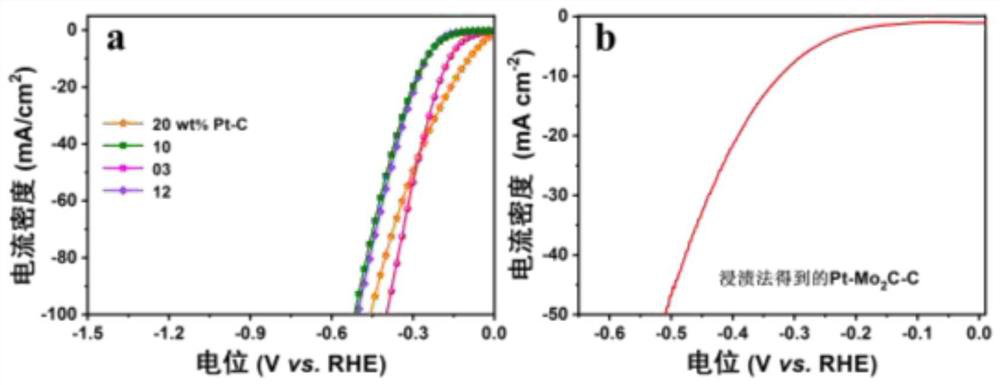

[0034] 4) Electrochemical test: take 4 mg of the catalyst prepared in step 3) and add it to 460 μl of alcohol, 500 μl of water and 40 μl of a 0.05% Nafion mixed solution with a mass concentration ...

Embodiment 13-24

[0038] Example 13-24 Preparation method of platinum carbide supported palladium single-atom catalyst with Pd-NENU-5 as precursor

[0039] 1) Mix a certain amount of phosphomolybdic acid and palladium chloride, 0.3g copper acetate, 0.15g glutamic acid, 0.2g trimesic acid, and stir to obtain Pd-NENU-5;

[0040] 2) Heat treatment of the Pd-NENU-5 precursor obtained in 1) in a tube furnace at 2 °C min -1 The heating rate was increased to 700 °C, calcined under nitrogen atmosphere for 6 h, and cooled to room temperature naturally;

[0041] 3) Disperse the catalyst obtained in 2) in 0.5M H 2 SO 4 in 50 °C stirring for 1 h to prepare the catalyst. The consumption of phosphomolybdic acid and palladium chloride is shown in Table 2.

[0042] 4) The electrochemical test method is the same as that of Example 01-12. like Figure 4 showed that the onset potential of catalyst 15 was -0.1 V and reached 10 mA cm -2 The required overpotential is 0.181 V, and the HER activities of Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com