Perovskite gain medium, preparation method thereof and application of perovskite gain medium in continuous optical pump laser at room temperature

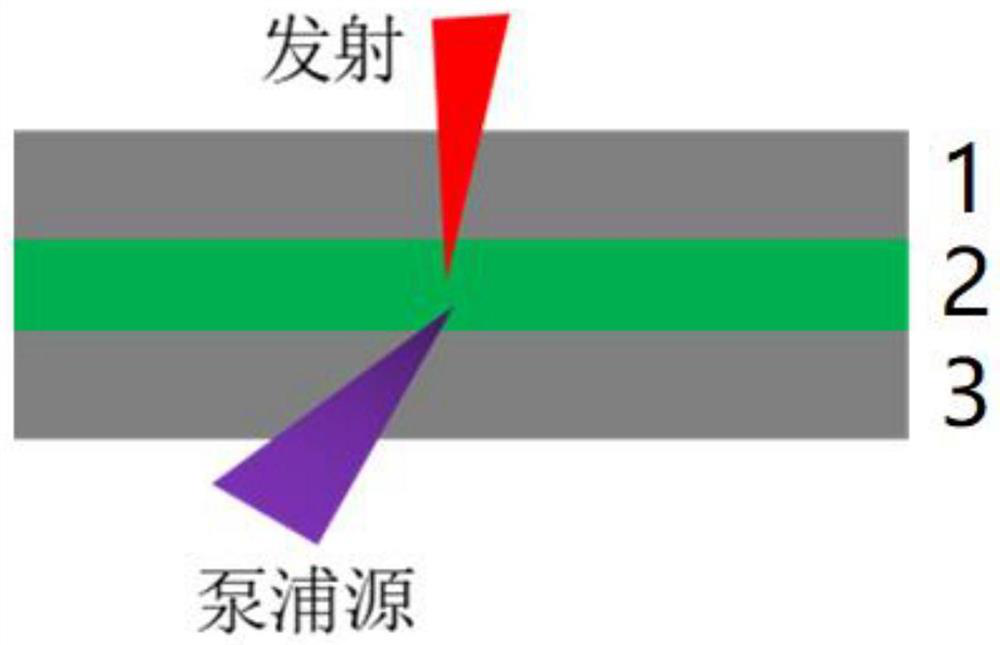

A gain medium, perovskite technology, applied in the field of lasers, can solve the problem of raising the excitation threshold, and achieve the effect of simple preparation method, reducing optical loss, and reducing the threshold of amplified spontaneous emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of a perovskite gain medium, comprising the following steps:

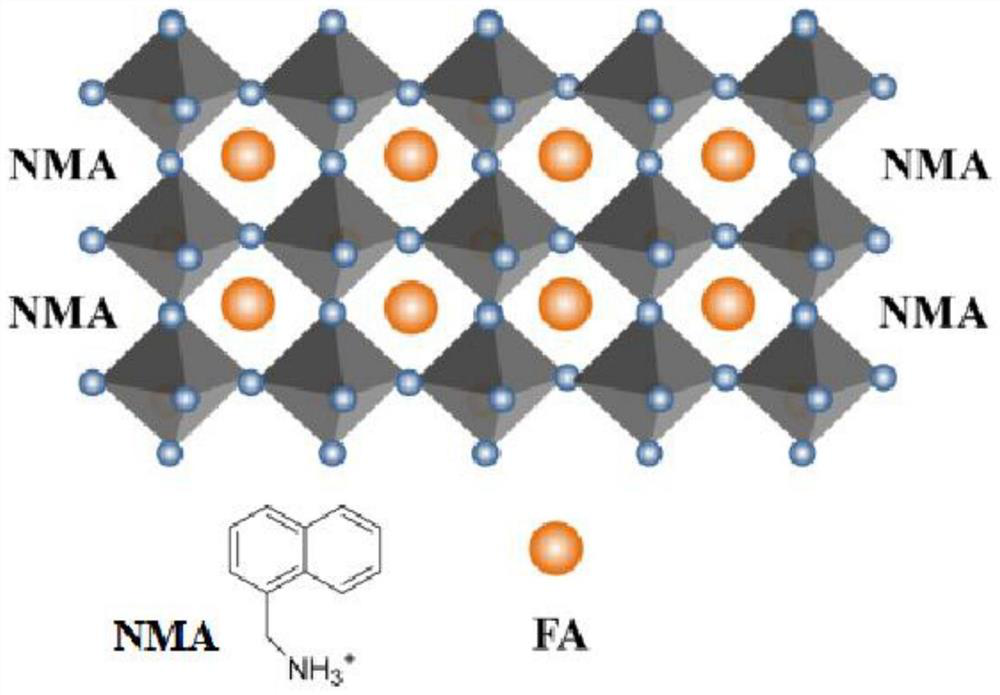

[0035] A) Combine LX, MX and PbX 2 Dissolved in solvent to obtain quasi-2D perovskite L 2 M n-1 Pb n X 3n+1 Precursor solution, n>1;

[0036] X is halogen anion, LX is n-butyl ammonium halide, isobutyl ammonium halide, aminovaleric acid halide, 1-naphthylmethyl ammonium halide, phenethyl amine halide, n-butyl amine halide, benzyl amine halide , one or more of phenylpropyl amine halide, phenylbutyl amine halide, n-octylamine hydrohalide, ethylamine hydrohalide and guanidine hydrohalide; MX is formamidine hydrohalide, One or more of methyl amine halide and cesium halide;

[0037] B) The quasi-2D perovskite precursor solution was coated on the surface of the substrate, and the anti-solvent was added dropwise during the coating process, and then the solvent was removed by annealing to obtain L2 M n-1 Pb n X 3n+1 perovskite gain medium;

[0038] The anti-solve...

Embodiment 1

[0065] The mirrors were sequentially placed in deionized water, acetone, and isopropanol for ultrasonic cleaning for 15 minutes, and the isopropanol was boiled for 3 minutes. The bottom DBR mirror was blown dry with nitrogen for use.

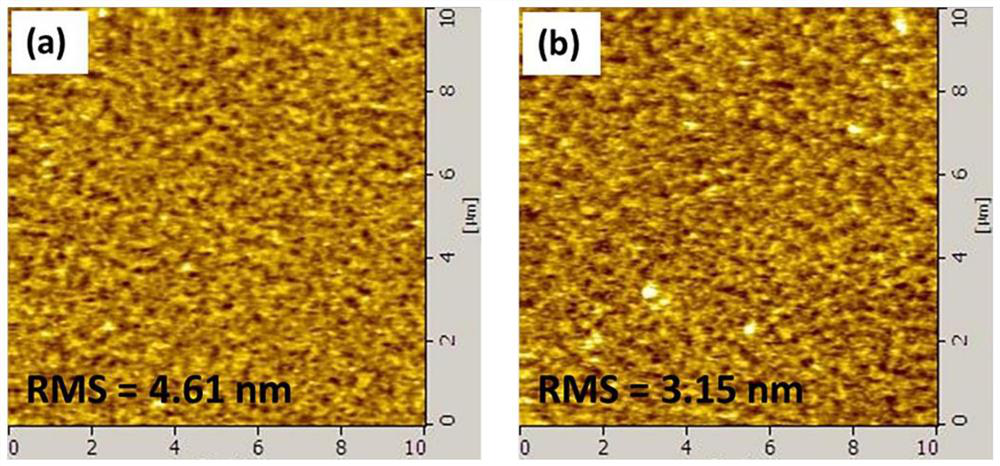

[0066] 0.6 mmol of lead bromide (PbBr 2 ), 0.48 mmol of formamidine hydrobromic acid (FABr), 0.24 mmol of 1-naphthylmethylammonium bromide (NMABr) were dissolved in 1 mL of N,N-dimethylformamide (DMF), and stirred at room temperature for 12 hours, The perovskite precursor solution was prepared, and the obtained solution was filtered for use. Then, the obtained perovskite precursor solution was spin-coated on the surface of the cleaned commercial bottom DBR mirror, the reflection center wavelength was 540 nm, the reflectivity of the mirror was 99.9%, and the high reflection area was 470-600 nm. The spin-coating speed was 4300 rpm, and the spin-coating time was 30 seconds. 0.12 mL of toluene was rapidly added to the rotating surface as an anti-so...

Embodiment 2

[0069] The mirrors were sequentially placed in deionized water, acetone, and isopropanol for ultrasonic cleaning for 15 minutes, and the isopropanol was boiled for 3 minutes. The bottom DBR mirror was blown dry with nitrogen for use.

[0070] 0.6 mmol of lead bromide (PbBr 2 ), 0.48 mmol of formamidine hydrobromic acid (FABr), 0.24 mmol of 1-naphthylmethylammonium bromide (NMABr) were dissolved in 1 mL of N,N-dimethylformamide (DMF), and stirred at room temperature for 12 hours, The perovskite precursor solution was prepared, and the obtained solution was filtered for use. Then, the obtained perovskite precursor solution was spin-coated on the surface of the cleaned commercial bottom DBR mirror, the reflection center wavelength was 540 nm, the reflectivity of the mirror was 99.9%, and the high reflection area was 470-600 nm. The spin coating speed was 4300 rpm, the spin coating time was 30 seconds, and 0.12 mL of ethyl acetate was rapidly added dropwise to the rotating surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com