Flotation method of o-hydroxy aromatic ketoxime as collecting agent in froth flotation and application of o-hydroxy aromatic ketoxime

A technology for pro-hydroxyaromatic ketoxime and hydroxyaromatic ketoxime is applied in the field of flotation in froth flotation, which can solve the problems of collector selectivity and collection capacity not meeting application requirements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

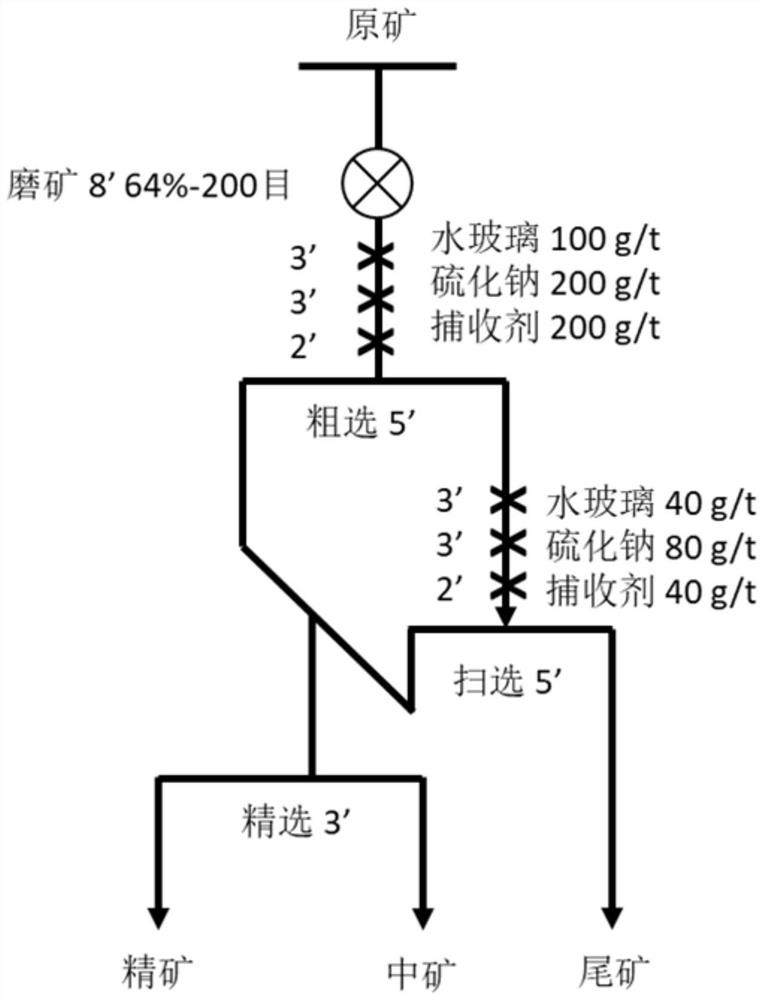

[0031] Example 1: Flotation experiment

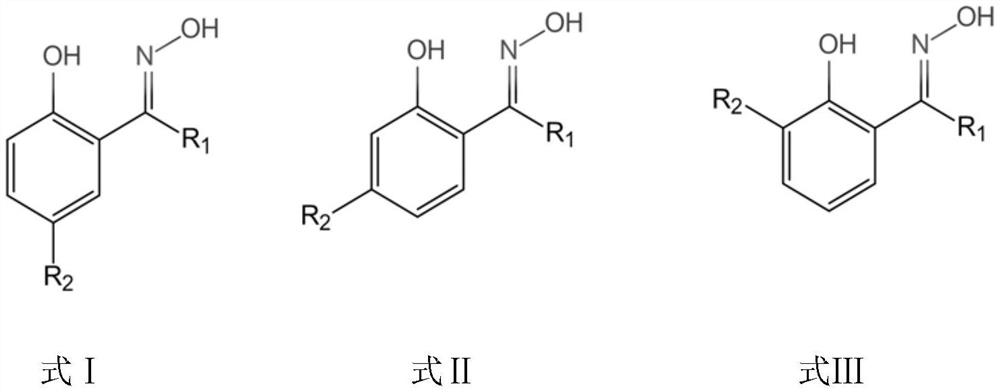

[0032] A copper mine in Africa is a mixed type of oxygen and sulfur, with an oxidation rate of 80-90%. The main useful mineral is malachite, and the raw ore grade is 1.6% copper. The collectors used in this example are: 109 (component is 2-hydroxy-5-ethylpropiophenone oxime (see formula V for structural formula)) and 2-hydroxypropiophenone oxime (see formula VI for structural formula), salicylic hydroxamic acid (see formula IV for structural formula) and octylhydroxime Acid flotation test. The compound synthesis of this scheme mainly adopts the esterification reaction of acid chloride and alkylphenol, followed by rearrangement reaction. Taking formula V as an example, the synthetic method is described, and the reaction of synthetic formula V is specifically as follows:

[0033] The first step esterification reaction (reaction equation see formula V-1)

[0034] Put 1.1 mol of ethyl phenol as a substrate in a four-necked flask and pl...

Embodiment 2

[0051] Embodiment 2: Flotation experiment

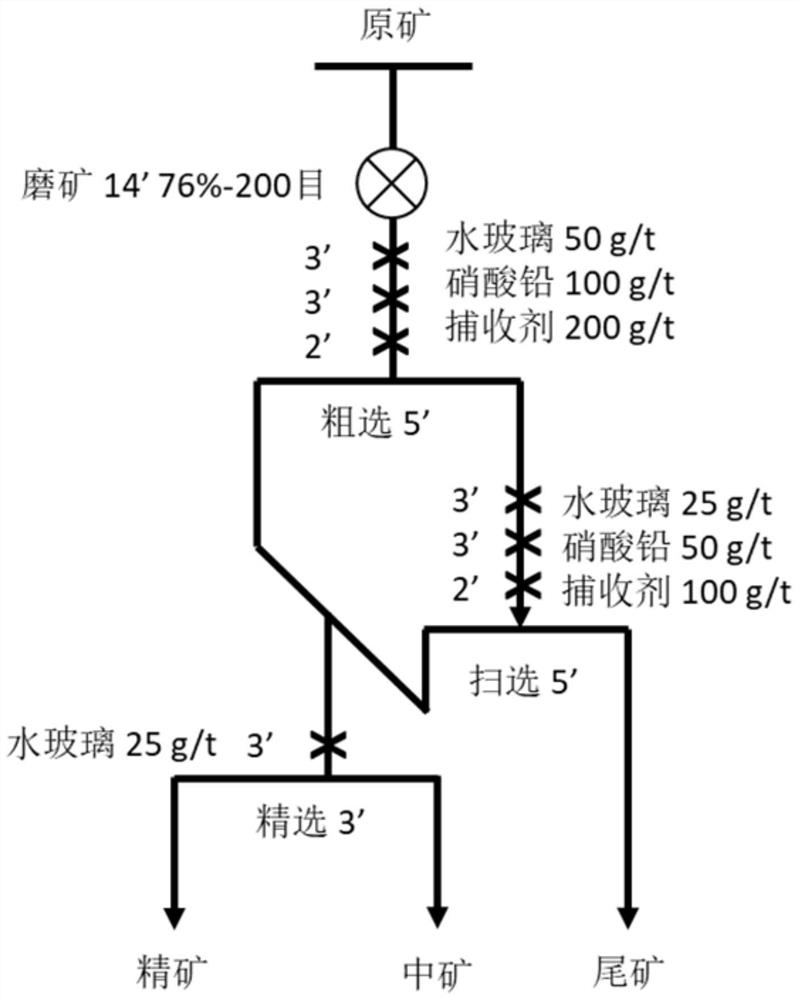

[0052] A tungsten mine in the south is scheelite, and the ore grade tungsten is 0.36%. The collector used in this embodiment has: 108 (the composition is 2-hydroxy-5-propyl acetophenone oxime, see formula VII for structural formula), 2-hydroxyacetophenone oxime (see formula VIII for structural formula), benzohydroxamic acid and octyl hydroxamic acid Select a small test and conduct a three-stage test of rough, fine, and sweep (for the experimental process, see figure 2 ). The more detailed operation process is as follows: use a ball mill to add water to the raw ore for ball milling to obtain preliminary pulp. The particle size of coarse ore powder in the preliminary slurry is 200 mesh, and the ore content is 28%. Then, add 50g / t of water glass, 100g / t of lead nitrate and 200g / t of collector to the preliminary slurry, and stir (rotating speed 1600rpm, time 3min, temperature 40°C) to obtain slurry I. After the pulp I has undergon...

Embodiment 3

[0057] Embodiment 3: the experiment of different collectors for the flotation effect of copper ore

[0058] The technological process of this embodiment is basically the same as that of Embodiment 1, the only difference lies in the selection of the collector and the preparation of copper concentrate products from a certain copper mine in Africa. The selection of specific collectors is shown in Table 4.

[0059] Table 4: Flotation indicators of a copper mine in Africa

[0060]

[0061]

[0062] According to the experimental results in Table 4, when the collectors No. 1-5 are used, the froth flotation yield, copper recovery rate and copper grade are all significantly improved. This shows that the compounds represented by the formula I to formula III of this scheme can be used as ideal collectors in the practical operation of ore dressing to improve the quality of concentrate and economic benefits. Moreover, the selection of each group in the compound has a very significa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com