Treatment method for low-friction solid-liquid composite lubrication of surface of aluminum-lithium alloy

An aluminum-lithium alloy and solid-liquid composite technology, applied in the field of tribology, can solve problems such as low friction, lack of lubrication mechanism, and inability to obtain low friction, and achieve the effects of reducing friction coefficient, improving tribological performance, and shortening the running-in period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

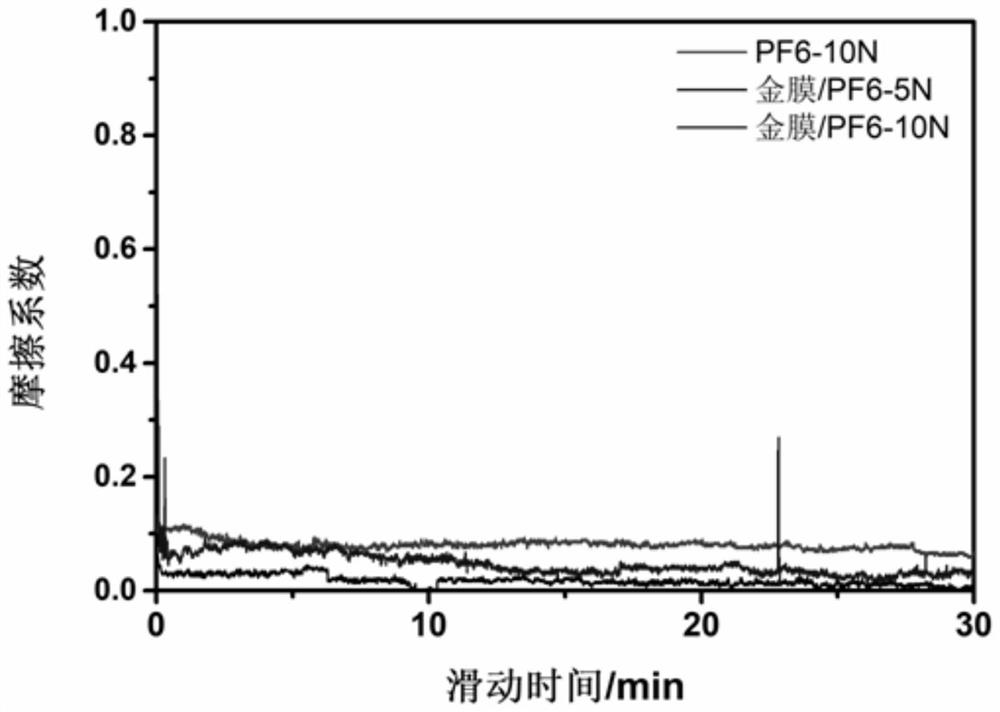

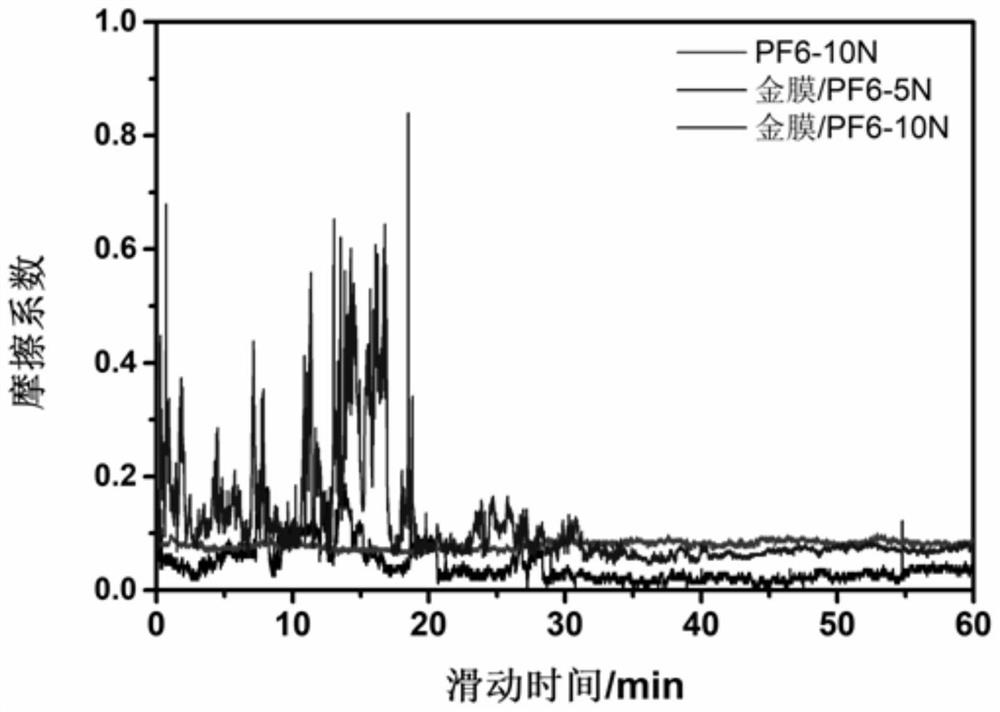

Examples

Embodiment 1

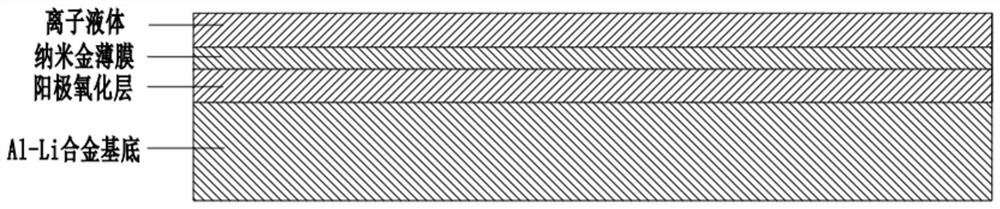

[0043] A method for treating low-friction solid-liquid composite lubrication on the surface of an aluminum-lithium alloy, comprising the following steps:

[0044] S1: Pretreating the surface of the aluminum-lithium alloy substrate; the aluminum-lithium alloy substrate is a rolled (subsurface) 2060-T8E30 aluminum-lithium alloy substrate, the surface roughness Ra is 0.384mm, and the size is 350×150 ×3mm.

[0045] Specifically, S101: carry out chemically pure ethanol ultrasonic degreasing on the aluminum-lithium alloy substrate, the ultrasonic power is 40W, the ultrasonic time is 10min, then rinsed with distilled water, and dried with a hair dryer at low temperature;

[0046] S102: deoxidize the cleaned and dried aluminum-lithium alloy substrate with 50g / L sodium hydroxide solution at 50°C for 13s;

[0047] S103: Rinse the deoxidized Al-Li alloy substrate with distilled water, and then use 30% HNO at room temperature 3 The solution is cleaned to remove the residual sodium hydroxi...

Embodiment 2

[0067] The difference between Example 2 and Example 1 is only that the aluminum-lithium alloy used in Example 2 is a 2060-T8E30 aluminum-lithium alloy substrate in a polished state (that is, bright surface), and all other operation steps are the same as those in Example 1. .

Embodiment 3

[0074] The difference between the third embodiment and the first embodiment is only that the ionic liquid used in step S4 is different, and other operation steps are the same as those of the first embodiment. Specifically, the aluminum-lithium alloy used in Example 3 is a rolled (subsurface) 2060-T8E30 aluminum-lithium alloy substrate, the surface roughness Ra is 0.384mm, and the size is 350×150×3mm. The ionic liquid is 1-octyl-3-methylimidazolium tetrafluoroborate (BF4 for short), and its structural formula is

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com