Device and method for preparing battery-grade iron phosphate by using byproduct ferrous sulfate

A technology of ferrous sulfate and ferric phosphate, which is applied in the direction of ferric sulfate, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low impurity removal rate, difficulty in strict control of consistency and quality stability, and difficult control of process conditions, etc. achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

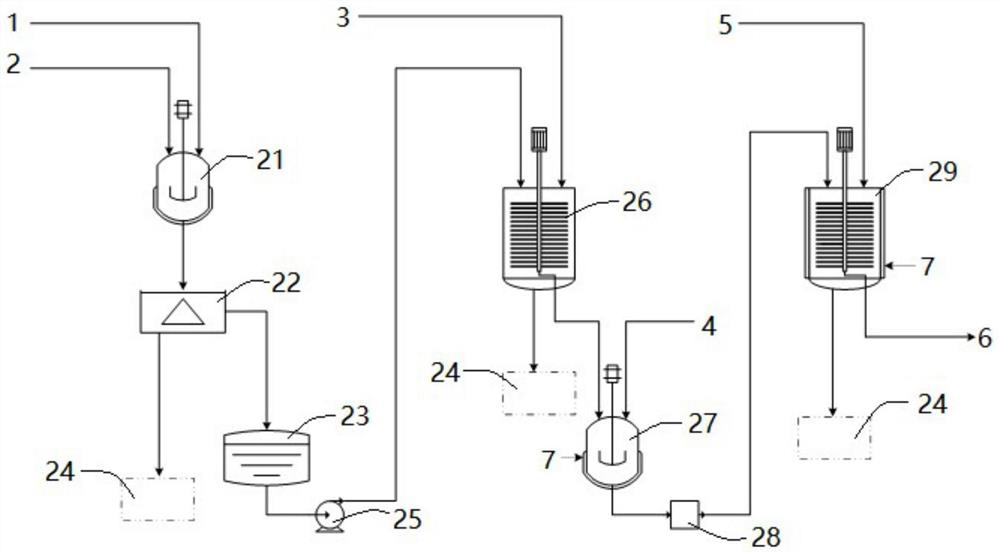

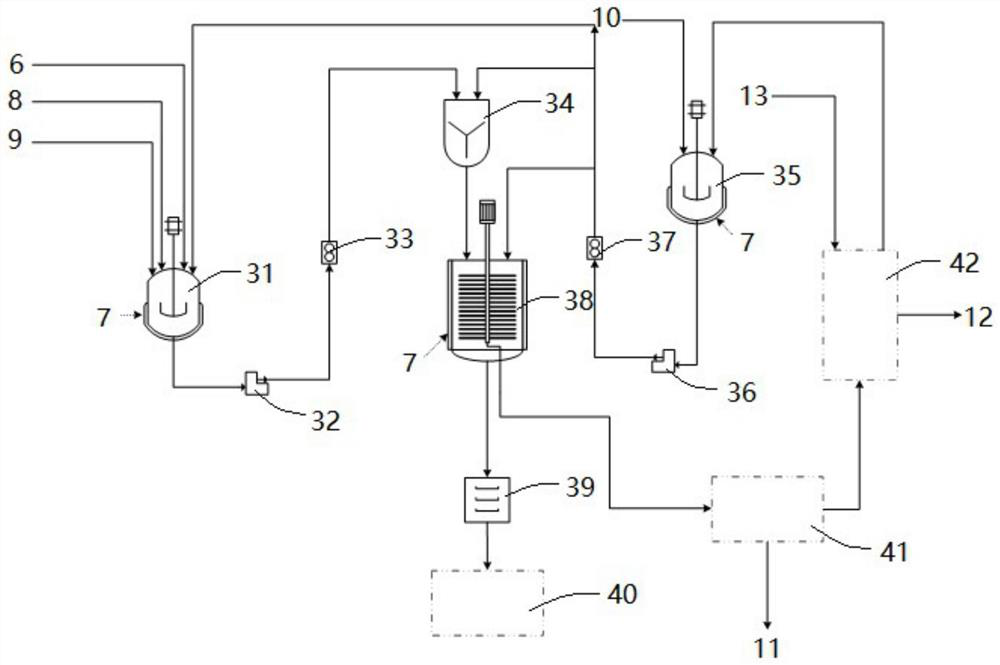

[0047] The invention purifies and purifies a large amount of by-product ferrous sulfate generated in the process of producing titanium dioxide by a sulfuric acid method, and uses it as an iron source to prepare battery-grade iron phosphate, so as to prepare a positive electrode material for lithium iron phosphate battery, so as to realize a titanium dioxide enterprise Resource utilization of ferrous sulfate solid waste to achieve the dual advantages of economy and environmental protection. Based on the above goals, the present invention proposes a device for preparing battery-grade iron phosphate by using by-product ferrous sulfate, including a purification device and a synthesis device. The purified liquid of the purification device is used as an iron source for the preparation of battery-grade iron phosphate in the synthesis device.

[0048] The invention is based on the chemical precipitation-hydrolysis method to purify the by-product ferrous sulfate. The hydrolysis conditi...

Embodiment 2

[0063] The invention also proposes a method for synthesizing iron phosphate by oxidative precipitation of ferrous salt in liquid phase. In the preparation process, isothermal premixing, step-by-step addition of lye, parallel feeding to control the flow ratio, and uniformity between the diaphragms of the liquid distributor are adopted. Engineering measures such as feeding, multi-blade strong shear mixing, in-situ discharge of clear liquid and in-situ washing of wet materials can strictly control various process conditions, so as to achieve product consistency and quality stability. The specific process steps of the present embodiment are described in detail below:

[0064] Purification steps:

[0065] 1) dissolve

[0066] The added amount of deionized water is calculated with reference to the designed handling capacity of each batch of titanium dioxide by-product ferrous sulfate and the solubility of ferrous sulfate in water, and is injected into the dissolving kettle 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com