Preparation method of all-organic composite photocatalytic material for photocatalytic production of hydrogen peroxide

A composite photocatalysis, hydrogen oxide technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low absorption efficiency , low charge conductivity, etc., to achieve the effect of reducing the recombination rate, simplifying the process flow, and improving the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 25g of melamine, put it in a crucible with a lid, place it in a muffle furnace at a rate of 5°C / min, heat it up to 550°C, keep it at a constant temperature for 3 hours, and after natural cooling, take it out and grind it to obtain a pale yellow powder g-C 3 N 4 ; Weigh 5g of pale yellow powder and 0.01g of 1,6,7,12,-tetrachloro-3,5,9,10-perylene tetracarboxylic dianhydride, grind the two, and put them into a porcelain boat after mixing evenly. In a tube furnace, in an argon atmosphere, the temperature was raised to 200 °C at a heating rate of 5 °C / min for 2 hours, and then taken out after natural cooling; then repeatedly washed with methanol and deionized water, vacuum dried and ground to obtain Brown powdery PI Cl EN.

Embodiment 2

[0040] Weigh 25g of melamine, put it into a crucible with a lid, place it in a muffle furnace at a rate of 5°C / min, heat it up to 550°C, keep it at a constant temperature for 3h, after natural cooling, take out and grind to obtain a pale yellow powder g-C 3 N 4 ; Weigh 5g of light yellow powder and 0.01g of 1,6,7,12,-tetrachloro-3,5,9,10-perylene tetracarboxylic dianhydride, grind the two, and put them into a porcelain boat after mixing evenly. In an argon atmosphere, the temperature was raised to 300°C at a heating rate of 5°C / min for 2 hours, and then taken out after natural cooling; then repeatedly washed with methanol and deionized water, vacuum dried and ground to obtain a brown color Powdered PI Cl EN.

Embodiment 3

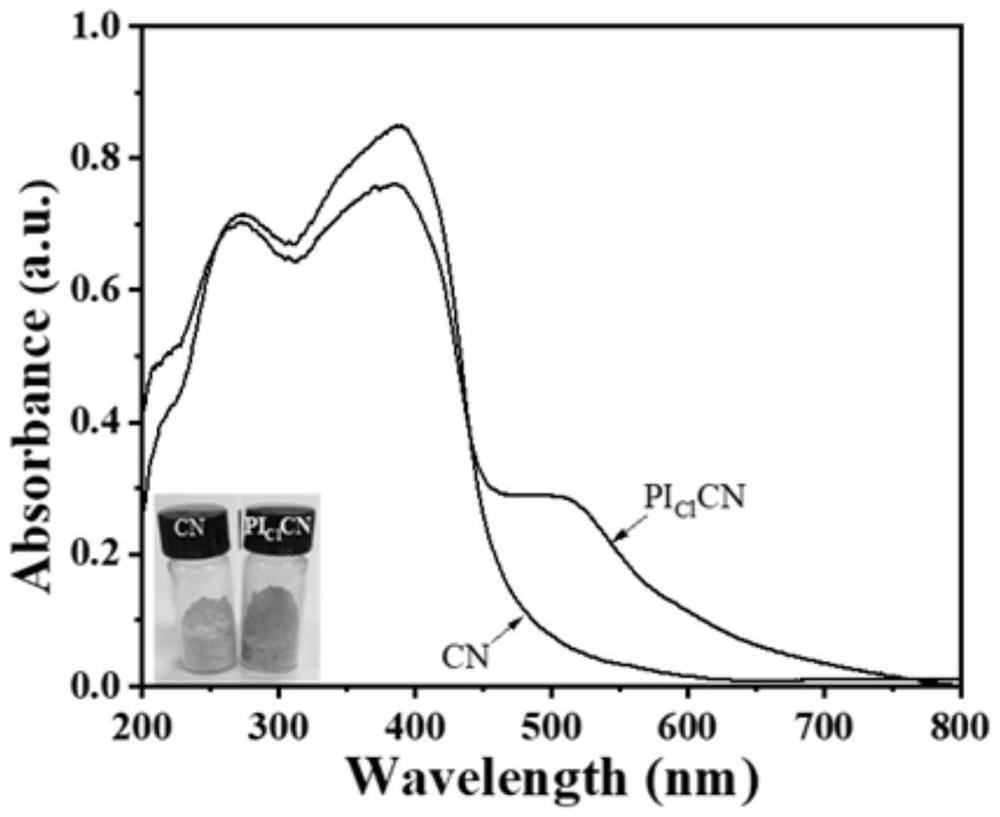

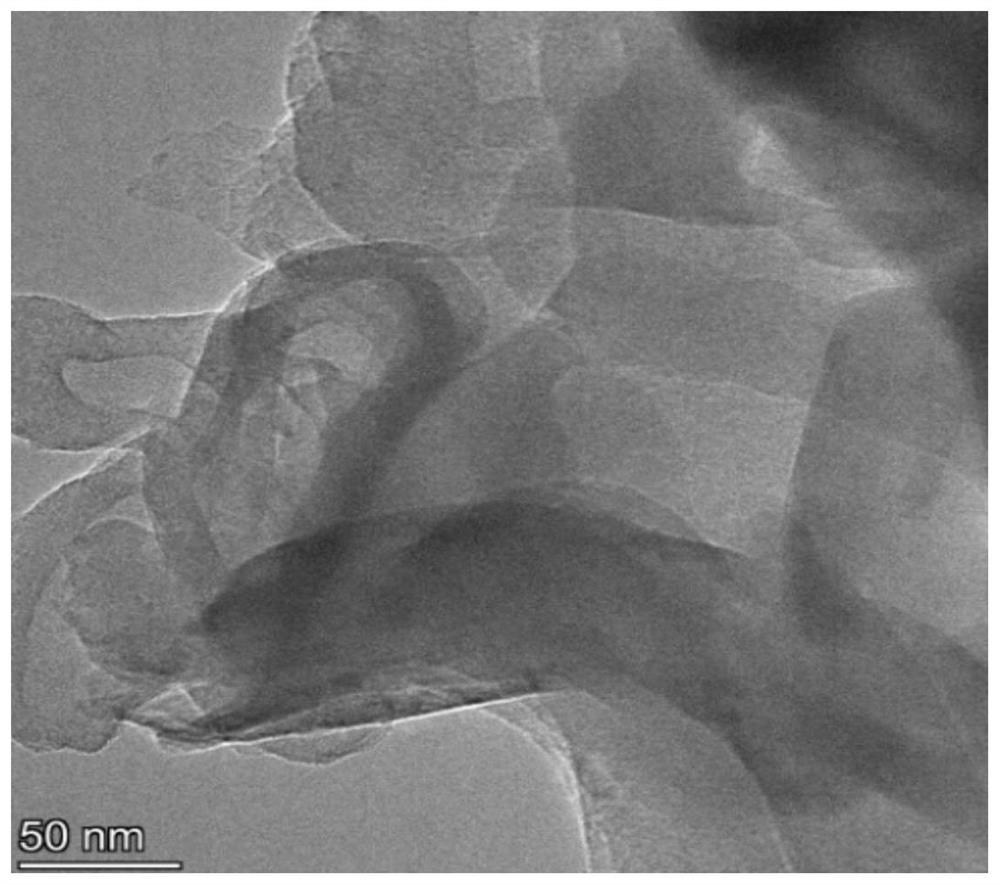

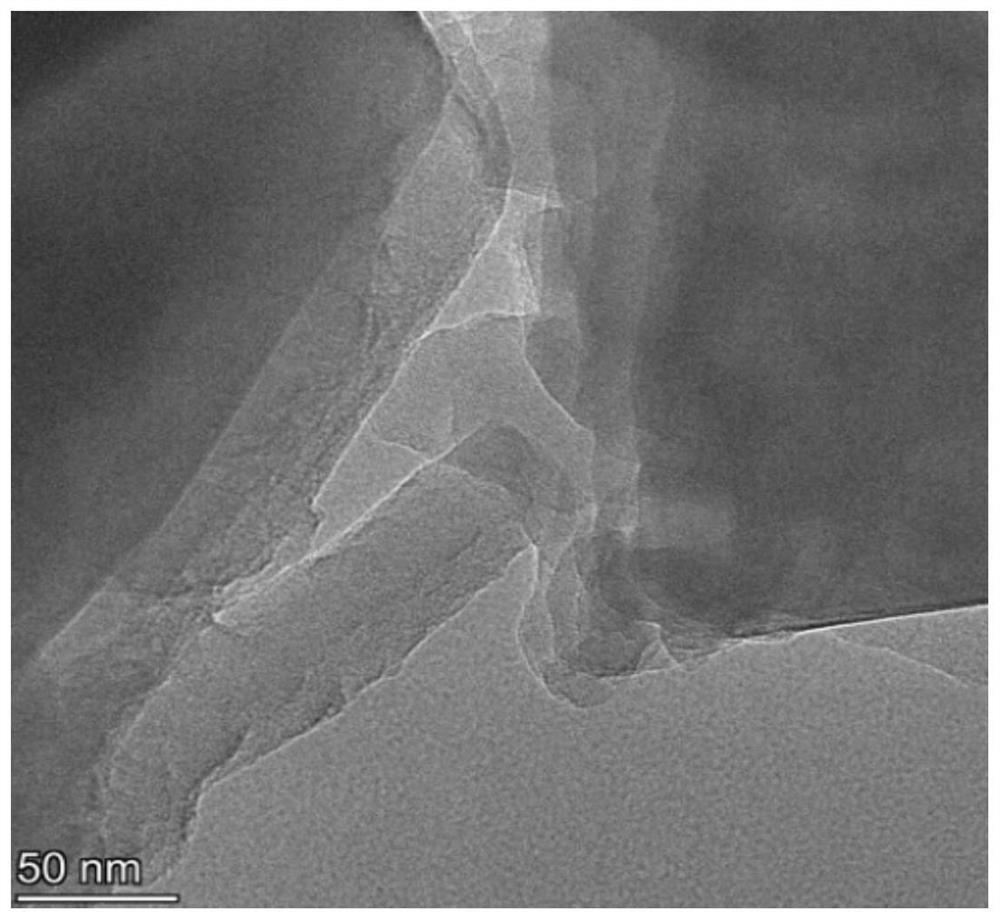

[0042] Weigh 25g of melamine, put it into a crucible with a lid, place it in a muffle furnace at a rate of 5°C / min, heat it up to 550°C, keep it at a constant temperature for 3h, after natural cooling, take out and grind to obtain a pale yellow powder g-C 3 N 4; Weigh 5g of pale yellow powder and 0.01g of 1,6,7,12,-tetrachloro-3,5,9,10-perylenetetracarboxylic dianhydride (PA Cl ), grind the two, mix them evenly and put them into a porcelain boat. As for the tube furnace, in an argon atmosphere, the temperature is raised to 400°C at a heating rate of 5°C / min for 2 hours, and then taken out after natural cooling; then Repeated washing with methanol and deionized water, vacuum drying and grinding to obtain PA through amidation reaction. Cl grafted on g-C 3 N 4 composite photocatalyst on PI Cl CN, due to the substitution of chlorine atoms at the PA bay site, the catalyst inhibits the π-π aggregation between perylene diimide molecules, which in turn affects the interfacial elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com