Kelp polypeptide, antibacterial repairing whitening toothpaste, preparation method and application

A technology of kelp and toothpaste, which is applied in the field of preparation of antibacterial, repairing and whitening toothpaste, kelp polypeptide, and achieves the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

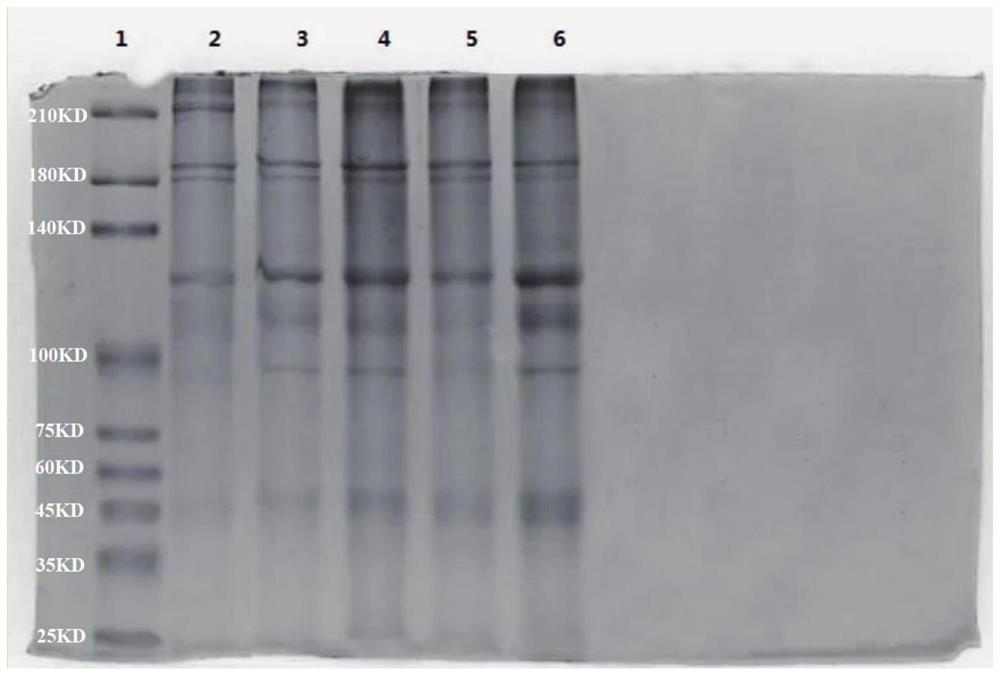

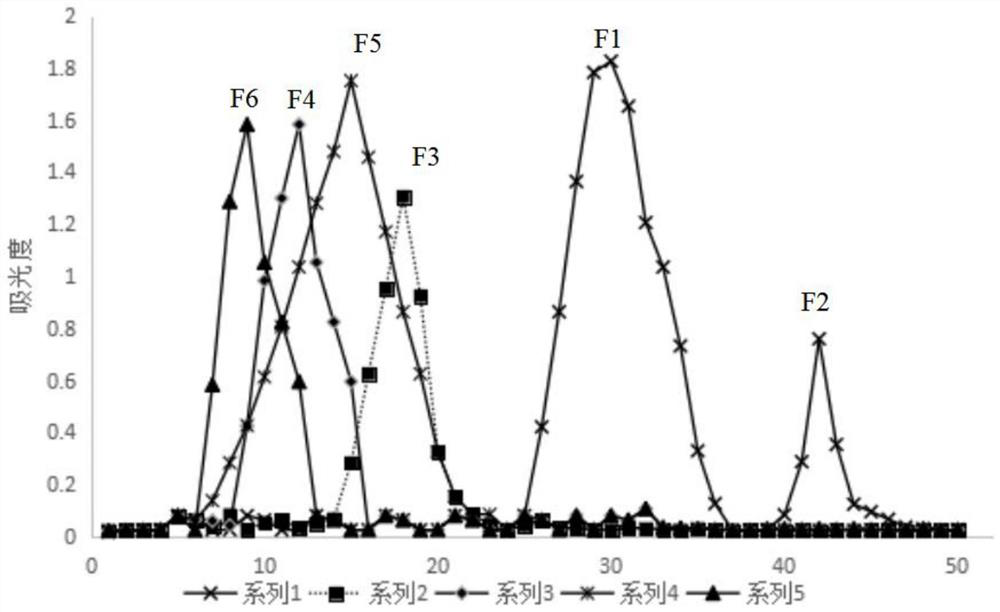

[0028] Preparation of kelp polypeptide

[0029] 1. Materials and methods

[0030] 1. Preprocessing

[0031] The dried commercially available Xiapu kelp was pulverized with a pulverizer and passed through a 40-mesh sieve to obtain kelp powder, which was sealed and stored at 4°C in the dark.

[0032] 2. Extract protein

[0033] Use low temperature freeze-thaw combined with ultrasonic to break cells of kelp powder, and then extract the broken cell liquid to obtain the protein liquid of kelp.

[0034] In a specific extraction process of kelp powder protein, accurately weigh 100g of kelp powder, add 300mL of distilled water, fully stir and disperse, let it stand for 1 to 5 days, and quickly freeze at -20°C for 4 hours, then transfer to 4°C environment. After being thawed in the middle, put it in an ultrasonic cleaner with 120W ultrasonic power for 30 minutes; then transfer to -20°C for rapid freezing for 4h, transfer to 4°C for thawing, and after 120W ultrasonic treatment for ...

Embodiment 7

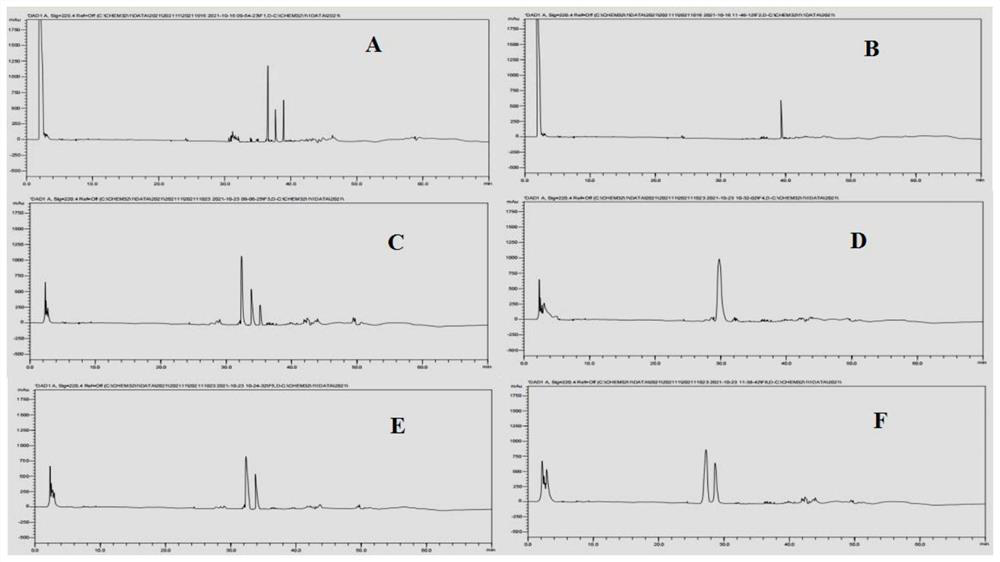

[0101] The preparation method of the polypeptide components in Example 7 is as follows: respectively accurately weigh 0.5 mg of kelp polypeptides T3, T6, T8, and T9 and dissolve them in 100 μL of pH6.8 trimaleic acid buffer to serve as the supply of 10 kinds of kelp polypeptides. The test solution was mixed with 1mL of 10ppm iron ion solution and 1mL of 0.1% (wt / vol) ascorbic acid solution in 2M hydrochloric acid by vortexing, incubated at room temperature for 5min, and 0.9mL of 11.3% trichloroacetic acid ( TCA), centrifuge at 2500g for 10min; take the precipitate and mix, wash with deionized water until neutral.

Embodiment 8

[0102] The preparation method of the polypeptide components in Example 8 is as follows: respectively accurately weigh 2 mg of kelp polypeptides T3, T6, T8, and T9 in 1 mL of distilled water, respectively, and mix them with 1 mL of 0.2 mM copper sulfate solution in 20 mL of pH6.8 Sanma. Add 1 mL of 11.3% TCA to the mixed solution, centrifuge at 2500 g for 10 min, take the precipitate and mix, and wash with deionized water until neutral.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com