Method for continuously synthesizing hexamethylene diisocyanate tripolymer

A technology of hexamethylene diisocyanate and trimer, which is applied in the field of continuous synthesis of hexamethylene diisocyanate trimer, can solve the problem of low quality of HDI trimer finished product, low catalytic efficiency of catalyst and technological process. Complex problems, to achieve the effect of easy industrialization, saving raw material costs, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

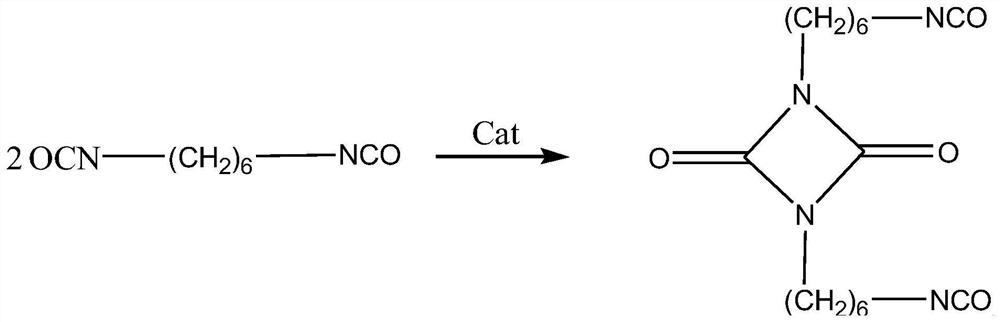

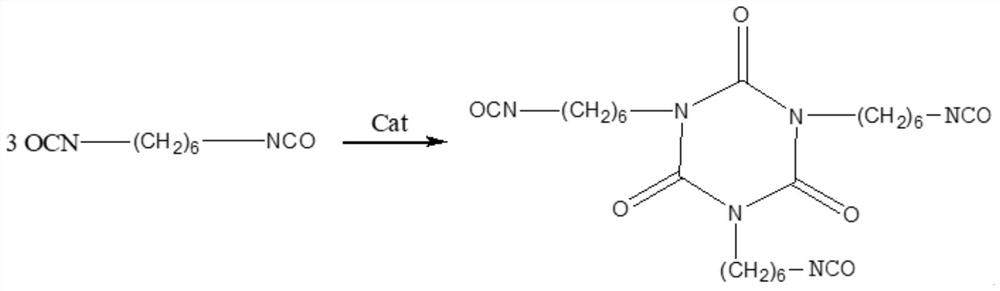

[0033] Under the catalysis of catalyst, hexamethylene diisocyanate is continuously synthesized to obtain hexamethylene diisocyanate (Hexamethylene Diisocyanate, HDI) trimer, and the reaction equation is such as figure 2 shown.

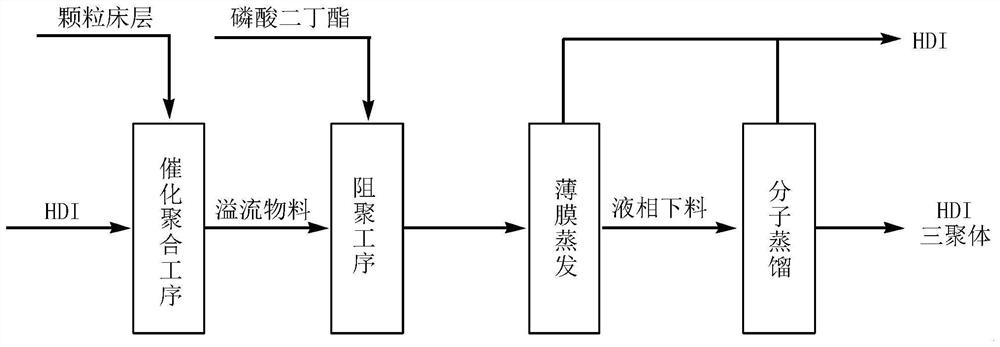

[0034] Process such as image 3 shown. The spherical silica particles containing the solid catalyst are filled into the tubular reactor to form a particle bed as a catalyst, wherein the aspect ratio of the tubular reactor is 5 to 20:1, and the diameter of the spherical particles containing the solid catalyst is 4 ~10mm, the porosity of the particle bed is 0.3~0.5, the volume ratio of the particle bed to the tubular reactor is 0.7~0.9, the solid catalyst is a kind of carboxylate and alkoxide, preferably potassium acetate, calcium acetate, propylene Potassium acetate, sodium acetate, cobalt acetate, zirconium ethoxide, titanium ethoxide, potassium ethoxide, calcium ethoxide.

[0035]The hexamethylene diisocyanate (HDI) preheated to 30~150℃ and nitrog...

Embodiment 2

[0038] The mesoporous silica supported potassium acetate was used as the catalyst, and the diameter of the catalyst particles was 5 mm. The height-diameter ratio of the tubular reactor is selected to be 10, the void ratio of the particle bed is 0.4, and the volume ratio of the particle bed to the tubular reactor is 0.85.

[0039] The internal temperature of the tubular reactor was 80°C. The HDI was preheated to 80°C for the feed, and the amount of nitrogen introduced per minute was 0.6 times the void volume of the tubular reactor. The reaction residence time was controlled to be 5h. The conversion rate of HDI is 60%, and the crude product of HDI trimer overflows to the transition tank.

[0040] Add dibutyl phosphate 0.0003 times the mass of the overflow material to the transition tank every hour. The synthetic liquid in the transition tank was passed through a thin film evaporator and a molecular distiller successively, and the temperature of the thin film evaporator was co...

Embodiment 3

[0043] The mesoporous silica supported calcium ethoxide was used as the catalyst, and the diameter of the catalyst particles was 5 mm. The height-diameter ratio of the tubular reactor is selected to be 10, the void ratio of the particle bed is 0.4, and the volume ratio of the particle bed to the tubular reactor is 0.85.

[0044] The internal temperature of the tubular reactor was 80°C. The HDI was preheated to 80°C for the feed, and the amount of nitrogen introduced per minute was 0.6 times the void volume of the tubular reactor. The reaction residence time was controlled to be 5h. The conversion rate of HDI is 60%, and the crude product of HDI trimer overflows to the transition tank.

[0045] Add dibutyl phosphate 0.0003 times the mass of the overflow material to the transition tank every hour. The synthetic liquid in the transition tank was passed through a thin film evaporator and a molecular distiller successively, and the temperature of the thin film evaporator was con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com